Displacement

Pump Repair

4. To disassemble the rest of the pump, remove the

packing

nut (416) and plug (405). See Fig. 33.

5. Use

a plastic mallet to tap the piston rod (424) down.

Pull

the rod out through the bottom of the cylinder

.

6.

Remove the throat packings. See Fig. 33.

WARNING

Always use the special sleeve removal tool, P/N

220–991,

to remove the sleeve. Other removal meth

-

ods

could cause the pump to rupture, resulting in seri

-

ous

injury

. If the sleeve cannot be removed easily us

-

ing the tool, return the sleeve and cylinder to your

Graco

distributor for removal.

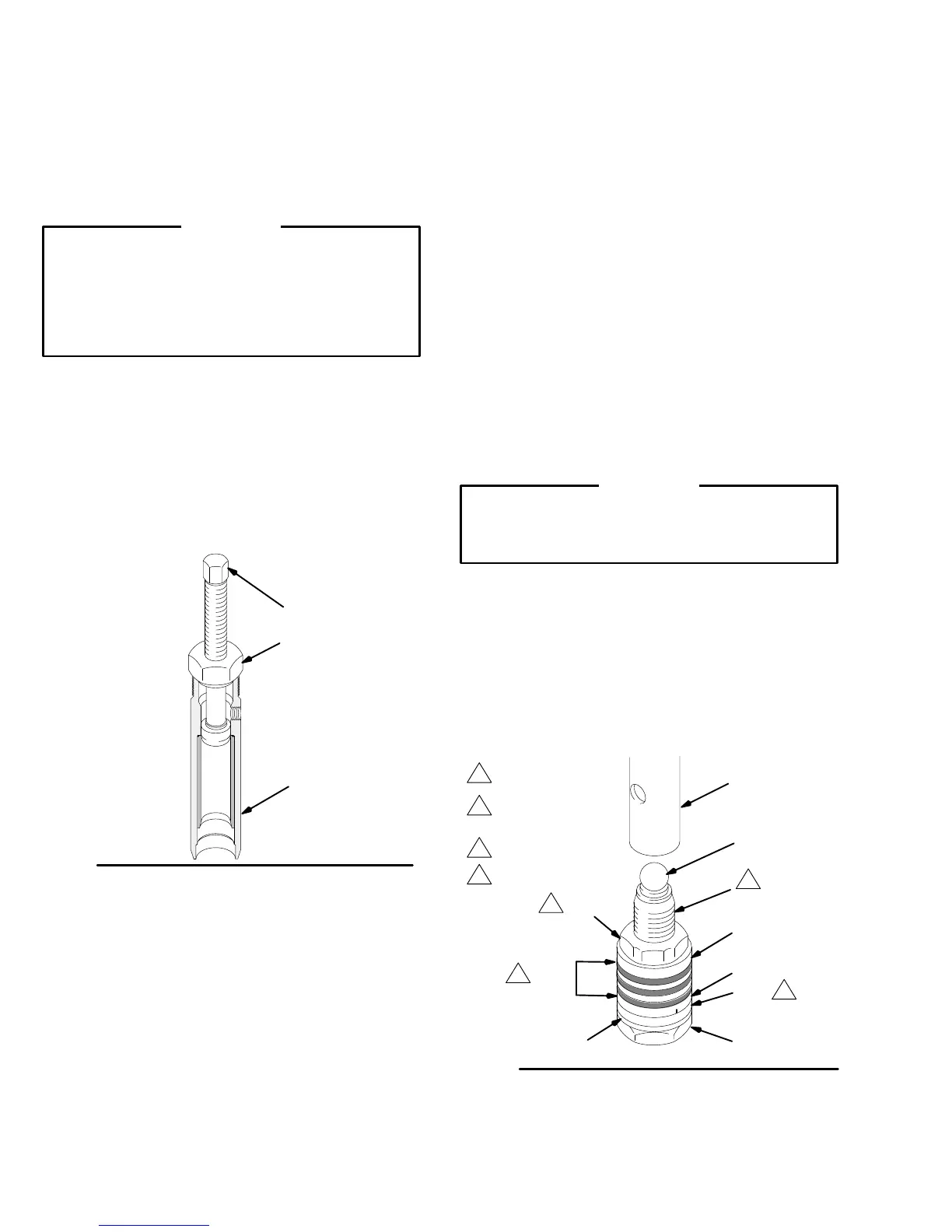

7. Remove the sleeve. Screw the large nut (B) of the

tool

into

the top of the cylinder (419). Screw down the

rod

(A) to push the sleeve out. Remove the tool. See

Fig.

29.

8. Clamp

the flats of the piston rod (424) in a vise. Loos

-

en

the retaining nut (41

1). Unscrew the piston valve

(422).

See Fig. 30.

9.

Disassemble the piston valve (422). See Fig. 30.

Fig. 29

419

B

A

0028

Reassembly Notes

1. Pump

Repair

Kit, P/N 220–877, is available. For the

best results, use all the new parts in the kit, even if

the

old ones still look good. Parts included in the kit

are shown with an asterisk, e.g., (410*) in the text

and

drawings.

2. Check

the outside of the piston rod (424) and the in

-

side of the sleeve (418) for scoring or scratches. If

the parts are damaged, new packings will not seal

properly.

Replace these parts if needed.

3. Alternate leather and plastic packings as shown in

Fig.

30. The lips of the throat “V” packings must face

down. The lips of the piston “V” packings must face

up.

The

lips of the U–cup seal (403) face down. Incor

-

rect installation damages the packings and causes

the

pump to leak.

4. Soak

leather packings in oil

before reassembling the

pump.

Reassembly Procedure

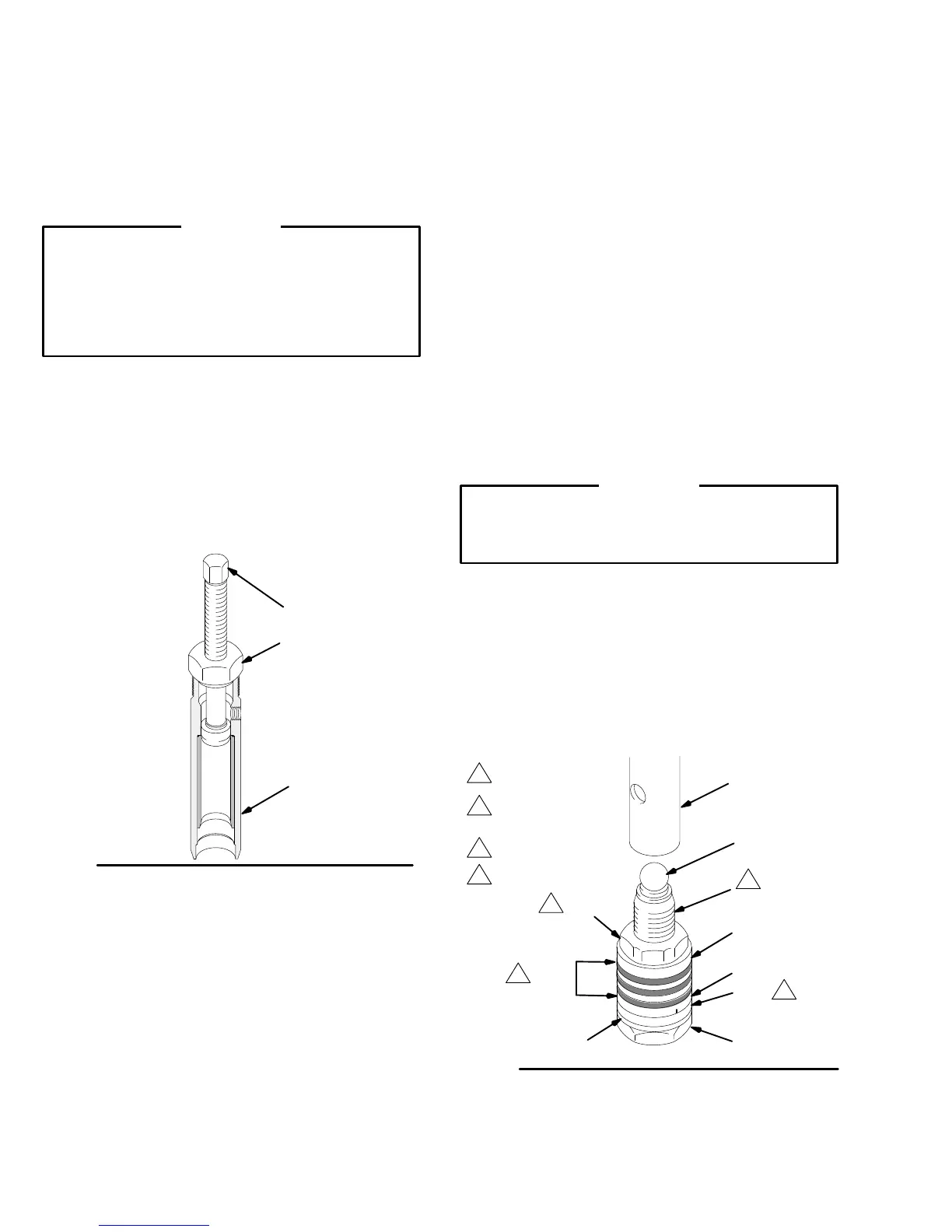

1. Stack

the backup washer (414), seal (403*),

female

gland

(415*), alternate the

packings (412*,406*), and

then male gland (410*) onto the piston valve (422).

See

Fig. 30.

2. Tighten

the packing retaining

nut (41

1) onto the pis

-

ton

valve (22) to the torque specified in Fig. 30.

3. Put the ball (425*) on the piston valve (422). See

Fig.

30.

CAUTION

Step

5, tightening the piston valve into the rod, is criti

-

cal.

Follow the procedure carefully to avoid damaging

the

packings by overtightening.

4. Apply

one drop of

adhesive, supplied, to the threads

of the piston valve. Then hand tighten the valve as-

sembly

into the piston rod just

until the nut (41

1) con

-

tacts

the rod. See Fig. 30.

NOTE:

Note the alignment

of the

piston (422) to the nut

(411).

Maintain this alignment through Steps 5,

6 and 7.

5. Place

the flats at the top of the rod (424) in a vise.

Torque

to

4 in-lb (0.35 N.m)

411

Fig.

30

422

410*

403*

415*

425*

*406

*412

424

0029

414

1

3

4

2

1

Apply

one drop

of sealant to

these threads

2

Lips face up

3

Lips face down

4

Loading...

Loading...