307-84718

Bearing

Housing & Connecting Rod

WARNING

To

reduce the risk of

serious injury

, including fluid in

-

jection

always follow the

Pressure Relief Procedure

Warning on page 14 before checking, adjusting,

cleaning or shutting off the sprayer.

Disconnect the

spark

plug!

NOTE:

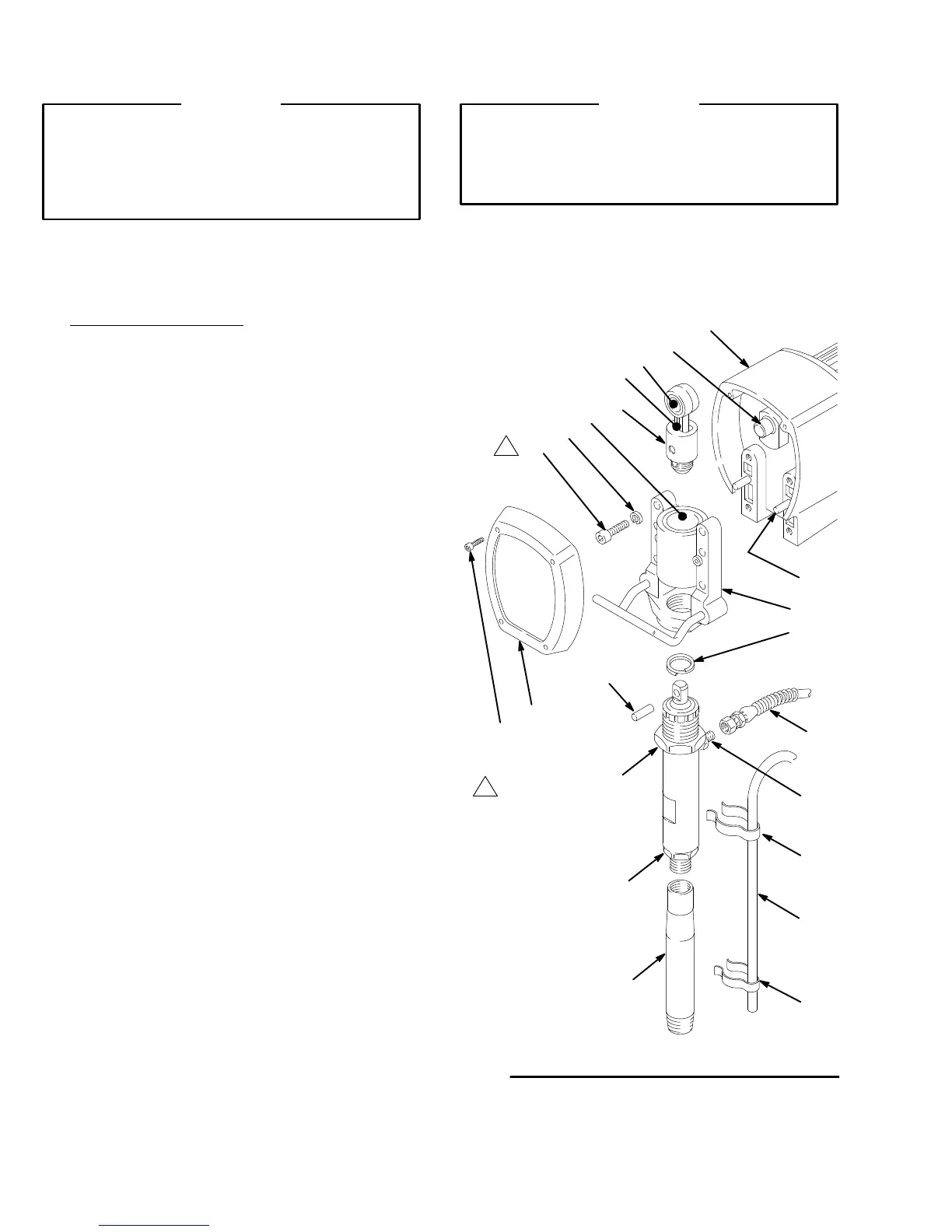

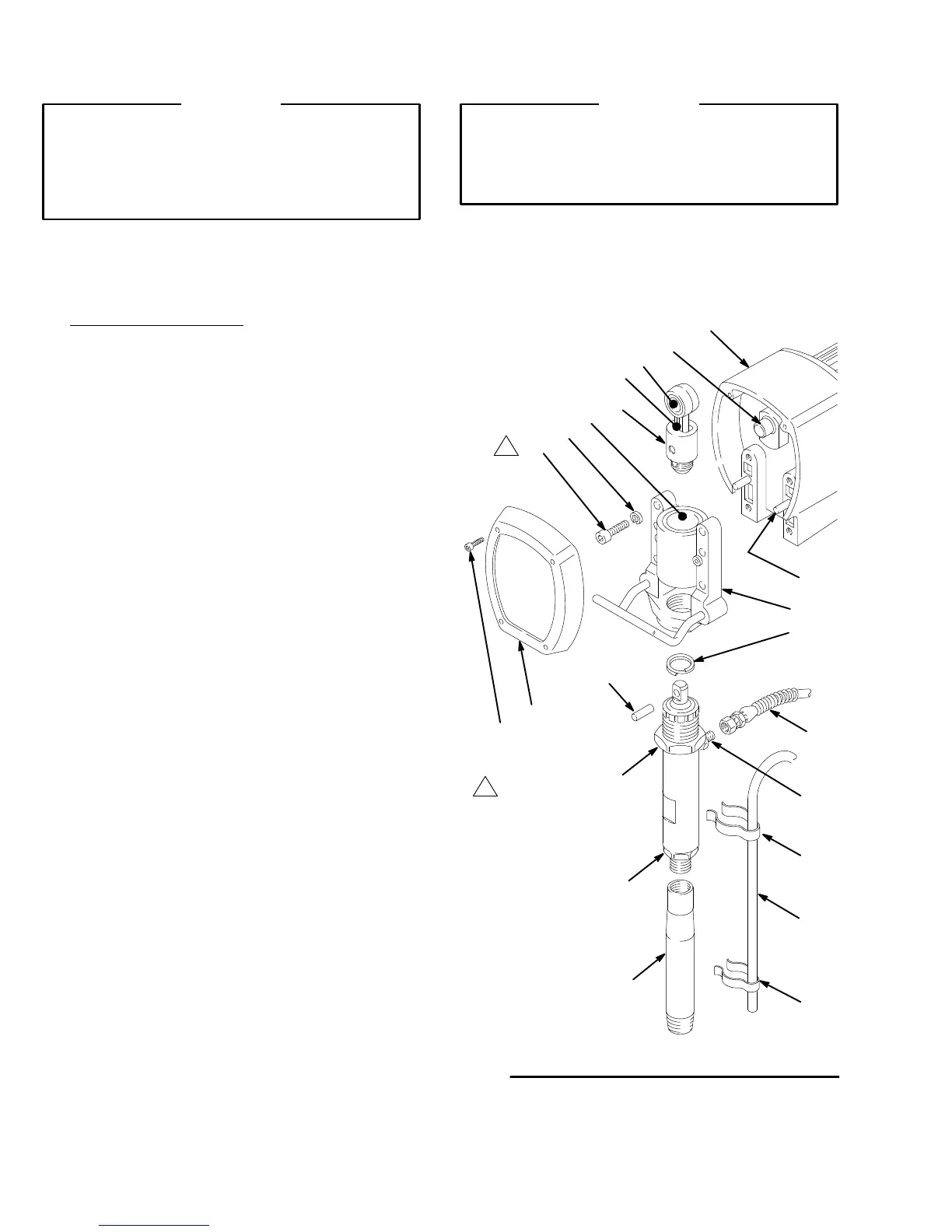

Steps 1 to 13 refer to Fig. 6.

1.

Remove the front cover and screws (23,68).

2. For upright models only:

Remove the spring clips

(112, 114) and the drain hose (113). Unscrew the

suction

tube (30) from the pump, holding a wrench on

the pump intake valve (B) to keep the pump from

loosening.

3. Disconnect the pump outlet hose (59) from the dis-

placement

pump outlet nipple (92).

4. Use

a screwdriver to push aside the retaining

spring

(26)

at the top of the pump. Push the pin (25) out the

rear.

5. Loosen the jam nut (27) with an adjustable wrench.

Unscrew

and remove the displacement pump.

6. Use

a

hex key wrench to remove the four screws (73)

and

lockwashers (74) from the bearing housing (21).

7. While

pulling the connecting rod (22) with one

hand,

lightly

tap the lower rear of the

bearing housing (21)

with

a plastic mallet to loosen it from the drive hous

-

ing

(20). Pull the bearing housing and the connecting

rod

assembly (22) of

f the drive housing.

8. Inspect

the crank (A) for excessive

wear and replace

parts

as needed.

9. Evenly

lubricate the inside of the bronze bearing

(C)

in

the bearing housing (21), and the inside of the con

-

necting

rod link (D),

with high–quality motor oil. Liber

-

ally

pack the roller bearing (E) in the connecting

rod

assembly

(22) with bearing grease.

10. Assemble

the connecting rod (22)

and bearing hous

-

ing (21).

11. Clean the mating surfaces of the bearing and drive

housings.

12. Align

the connecting rod with the crank (A) and care

-

fully align the locating pins (F) in the drive housing

(20)

with the holes in the bearing housing (21). Push

the bearing housing onto the drive housing or tap it

into

place with a plastic mallet.

CAUTION

DO

NOT use the bearing housing screw (73) to align

or seat the bearing housing with the drive housing.

These parts must be aligned using the locating pins

(F),

to help avoid premature bearing wear

.

13. Install the screws (73) and lockwashers (74) on the

bearing housing. Tighten evenly to 300 in–lb (34

N.m).

14. Refer

to

Installing the Pump

on page 31.

Fig. 6

73

27

22

114

113

112

0149

30

25

23

68

26

21

59

92

D

E

A

F

20

74

B

C

Torque

to

300 in–lb

(34 N.m)

Loading...

Loading...