Drive

Housing

WARNING

To

reduce the risk of

serious injury

, including fluid in

-

jection

always follow the

Pressure Relief Procedure

Warning on page 14 before checking, adjusting,

cleaning or shutting off the sprayer.

Disconnect the

spark

plug!

NOTE:

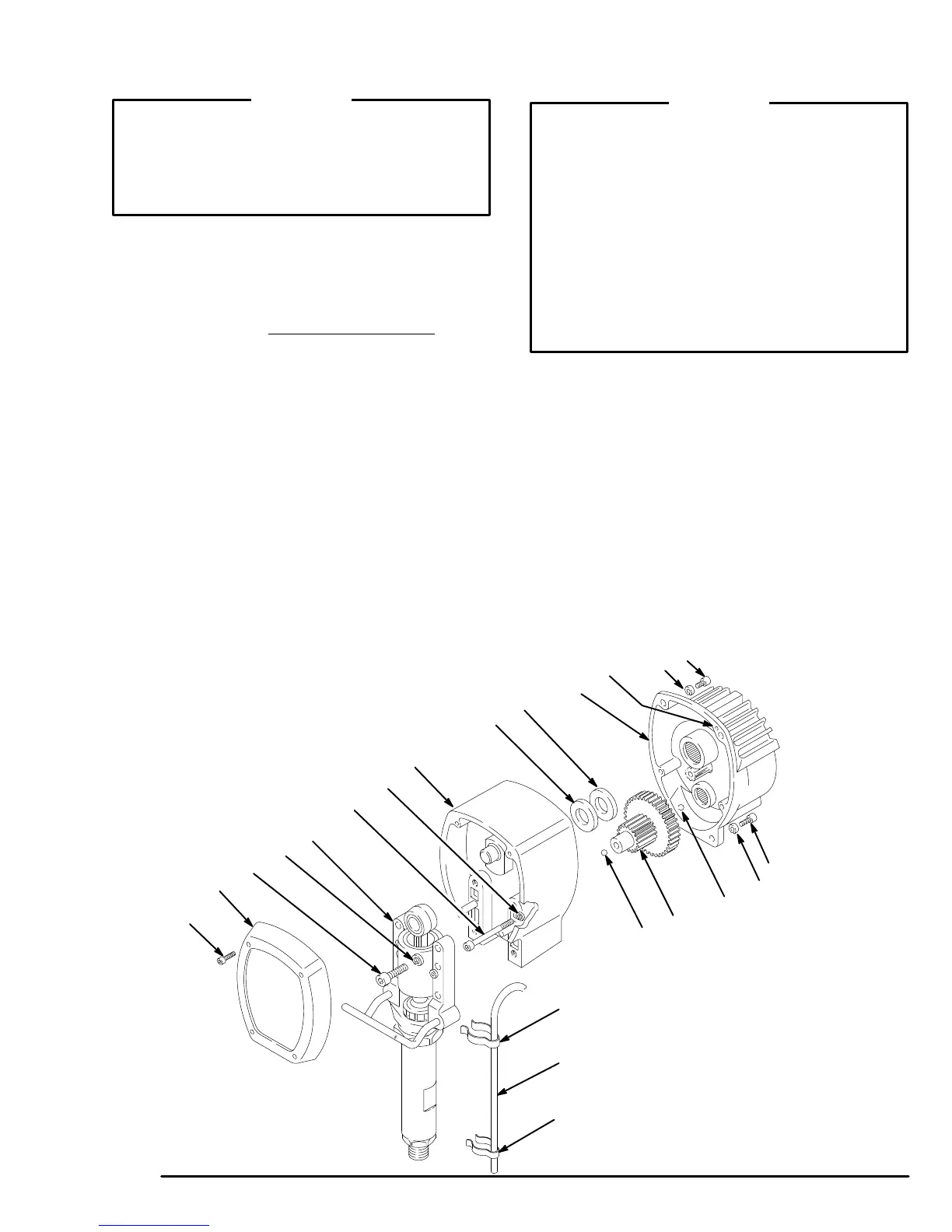

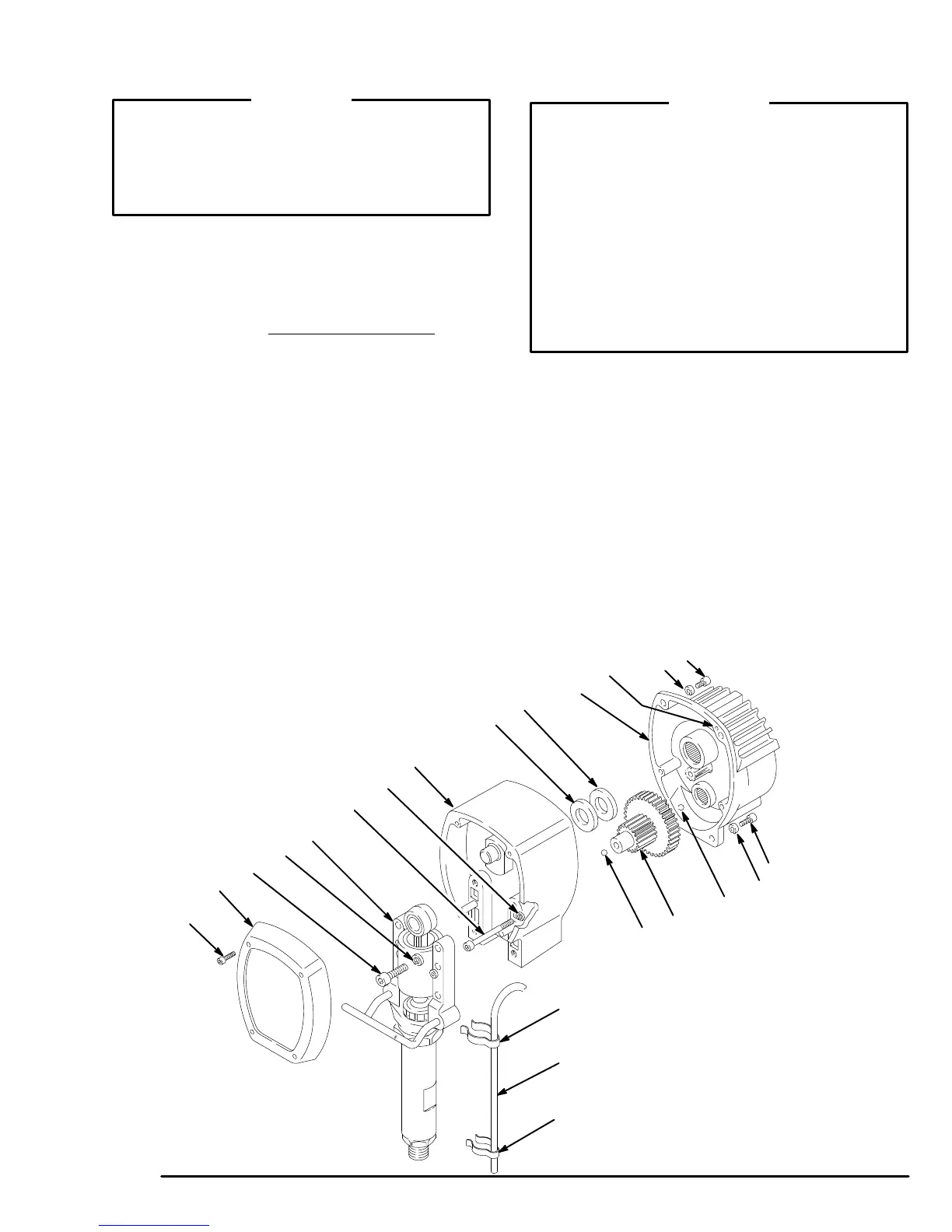

Refer to Fig. 7 for this procedure.

1.

Remove the front cover and screws (23,68).

2. Disconnect

the pump outlet hose from the displace

-

ment

pump

nipple. For the upright carts only

, remove

the spring clips (112, 114) and the drain hose (113)

from

the pump.

3. Remove the four screws (73) and lockwashers (74)

from

the bearing housing (20).

4. Lightly

tap the back of the bearing

housing (21) with

a plastic mallet. Pull the pump, bearing housing and

connecting rod away from the drive housing as one

assembly.

5. Remove the two screws (24)

and lockwashers (1

1).

Remove

the four screws (10) and lockwashers (1

1).

6. Lightly tap around the drive housing (20) to loosen

the drive housing. Pull the drive housing straight off

the

pinion housing. Be prepared to support the gear

cluster

(18), which may also come out.

CAUTION

DO NOT drop the gear cluster (18) when removing

the

drive housing (20). The gear cluster is easily dam

-

aged.

The gear may stay engaged in the drive hous

-

ing

or pinion housing.

DO

NOT lose the thrust balls

(20c or 19d) located at

each

end of the gear cluster

, or allow them to fall be

-

tween the gears. The ball, which is heavily covered

with grease, usually stays in the shaft recesses, but

could be dislodged. If the balls are caught between

the gears and not removed, they

will seriously dam

-

age

the drive housing. If the balls are not in place, the

bearings

will wear prematurely

.

7. Liberally apply bearing grease to the gear cluster

(18).

A tube

of grease is supplied with each replace

-

ment gear cluster. Use a full 6 oz. (160 grams) of

grease.

Be sure the thrust balls (20c and 19d) are in

place.

8.

Place the bronze colored washer (20a)

and then the

silver–colored washer (20b) on the shaft protruding

from

the big bearing of the drive housing (20). Align

the gears and push the new drive housing straight

onto

the pinion housing and locating pins (B).

9. Starting at Step 4, work backwards to reassemble

the sprayer. Or, move ahead to the next section in

this

manual if further service is needed.

Fig. 7

68

23

11

20

20a

20b

19

11

10

10

11

19d

18

20c

112

114

113

B

21

0170

24

73

74

Loading...

Loading...