Displacement Pump

311797S 17

Displacement Pump

GH130 Only

(Figures 7-12)

See manual 311845 for pump repair instructions

Removal

1 Flush pump.

2 Relieve pressure, page 7.

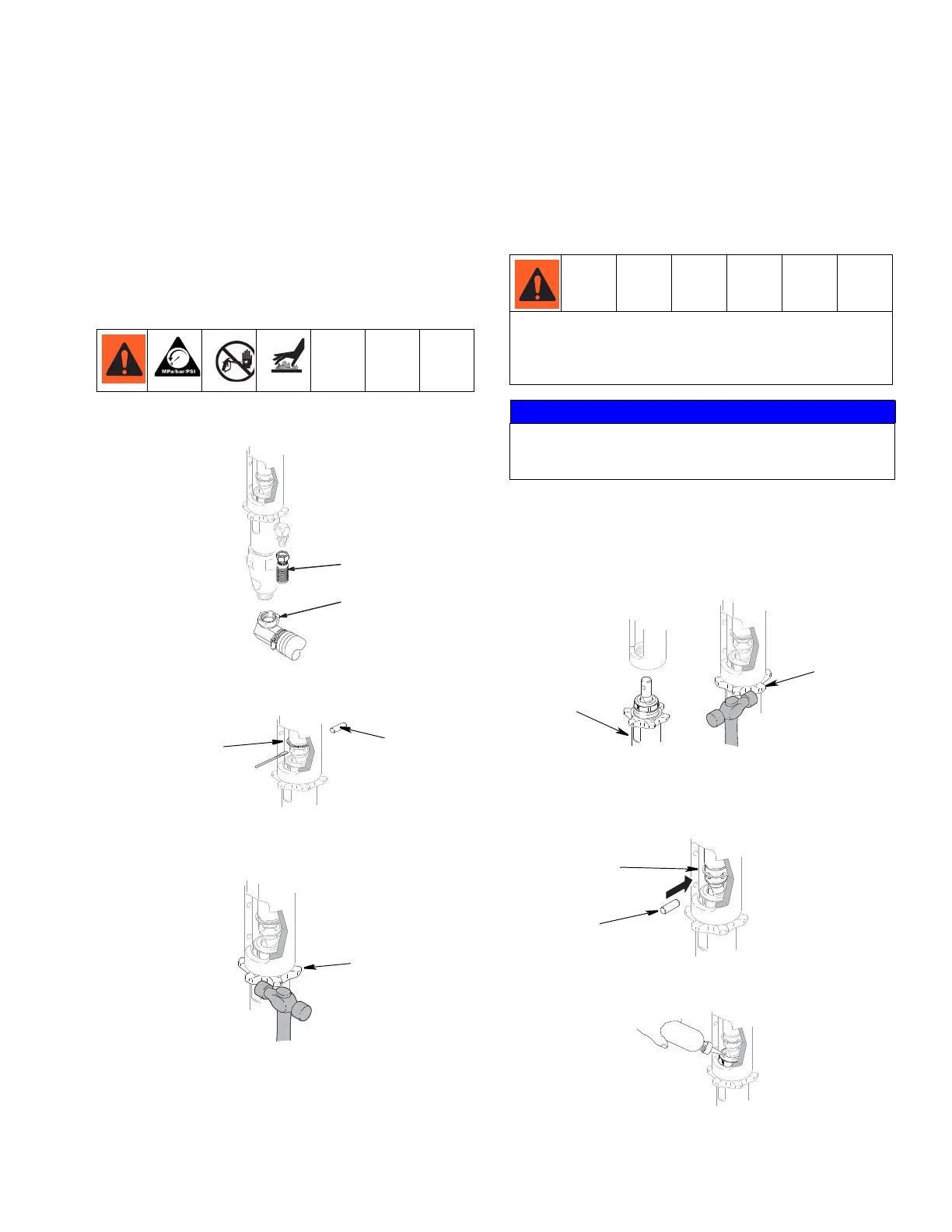

3 (Fig. 7) Remove suction tube (114) and paint hose (63)

(remove at swivel end).

FIG. 7

4 (Fig. 8) Push retaining ring (120) up; push out pin (92).

FIG. 8

5 (Fig. 9). Loosen jam nut (86). Unscrew pump (111).

FIG. 9

Installation

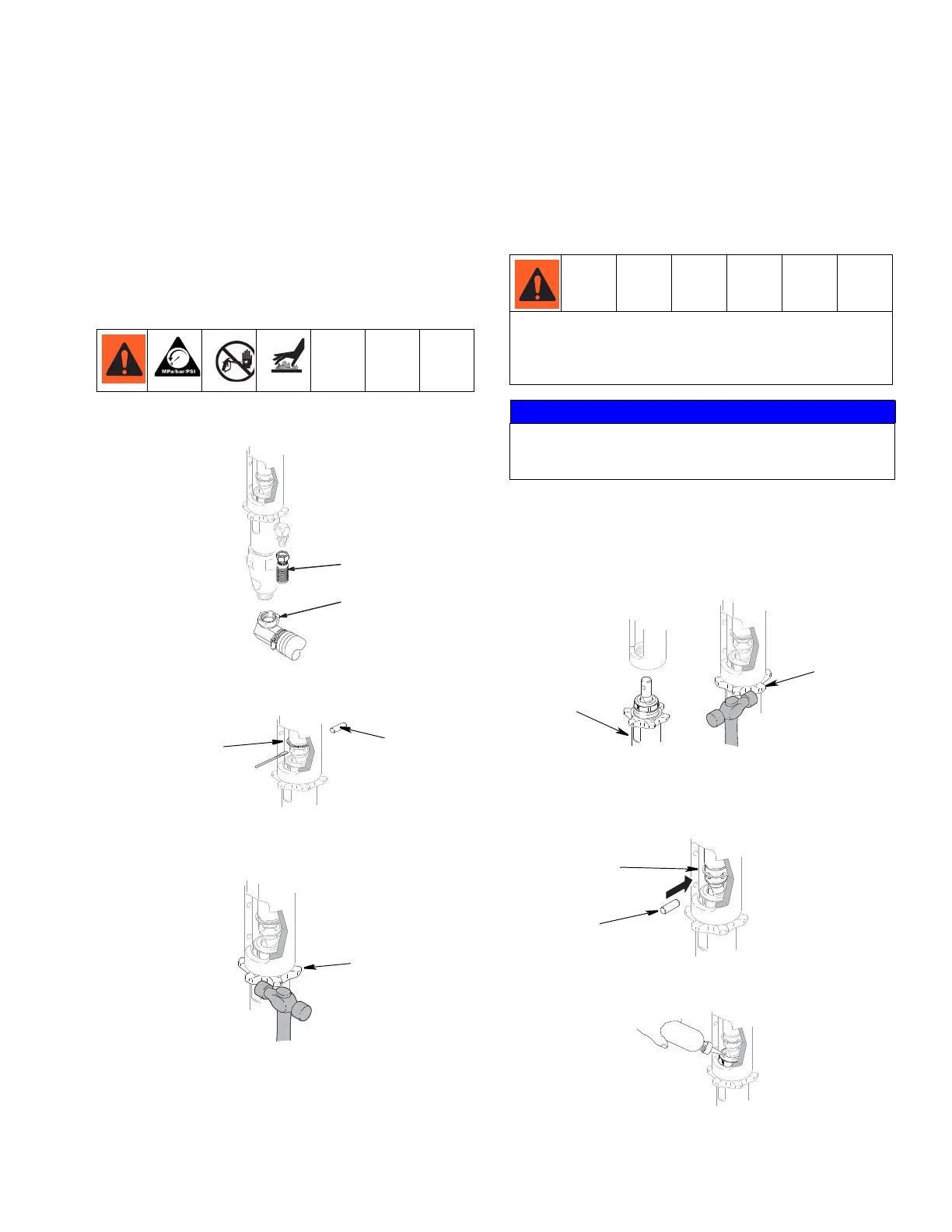

1 (Fig 10) Screw jam nut (86) to bottom of pump (111)

threads. Screw pump (111) completely into manifold.

Unscrew pump (111) from manifold until pump outlet

aligns with hose. Hand tighten jam nut (86), then tap 1/8

to 1/4 turn with hammer or torque to 75 ft-lb (101 N·m).

FIG. 10

2 (Fig. 11) Slowly pull engine starter rope until pump rod pin

hole is aligned with hydraulic rod hole. Fig. 8. Push pin

(92) into hole. Push retaining ring (120) into groove.

FIG. 11

3 (Fig. 12) Fill packing nut with Graco TSL.

If pin (92) works loose, parts could break off and project

through the air, resulting in serious injury or property

damage. Make sure pin is properly installed.

CAUTION

If the pump jam nut (86) loosens during operation, the

threads of the bearing housing and drive train will be dam-

aged. Tighten jam nut (86) as specified.

FIG. 12

Loading...

Loading...