General Repair Information

6 311797S

General Repair Information

1 Keep all screws, nuts, washers, gaskets, and electrical

fittings removed during repair procedures. These parts

are not normally provided with replacement assemblies.

2 Test repair after problem is corrected.

3 If sprayer does not operate properly, review repair

procedure to verify procedure was done correctly. If

necessary, see Troubleshooting Guide, page 7, for other

possible solutions.

4 Install belt guard before operation of sprayer and replace

if damaged. Belt guard reduces risk of pinching and loss

of fingers; see preceding WARNING.

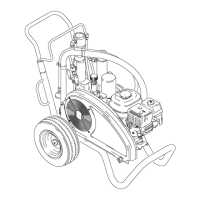

Grounding

Ground sprayer with grounding clamp to earth ground

for safe sprayer operation when using solvent-based

materials. Fig. 1.

F

IG. 1

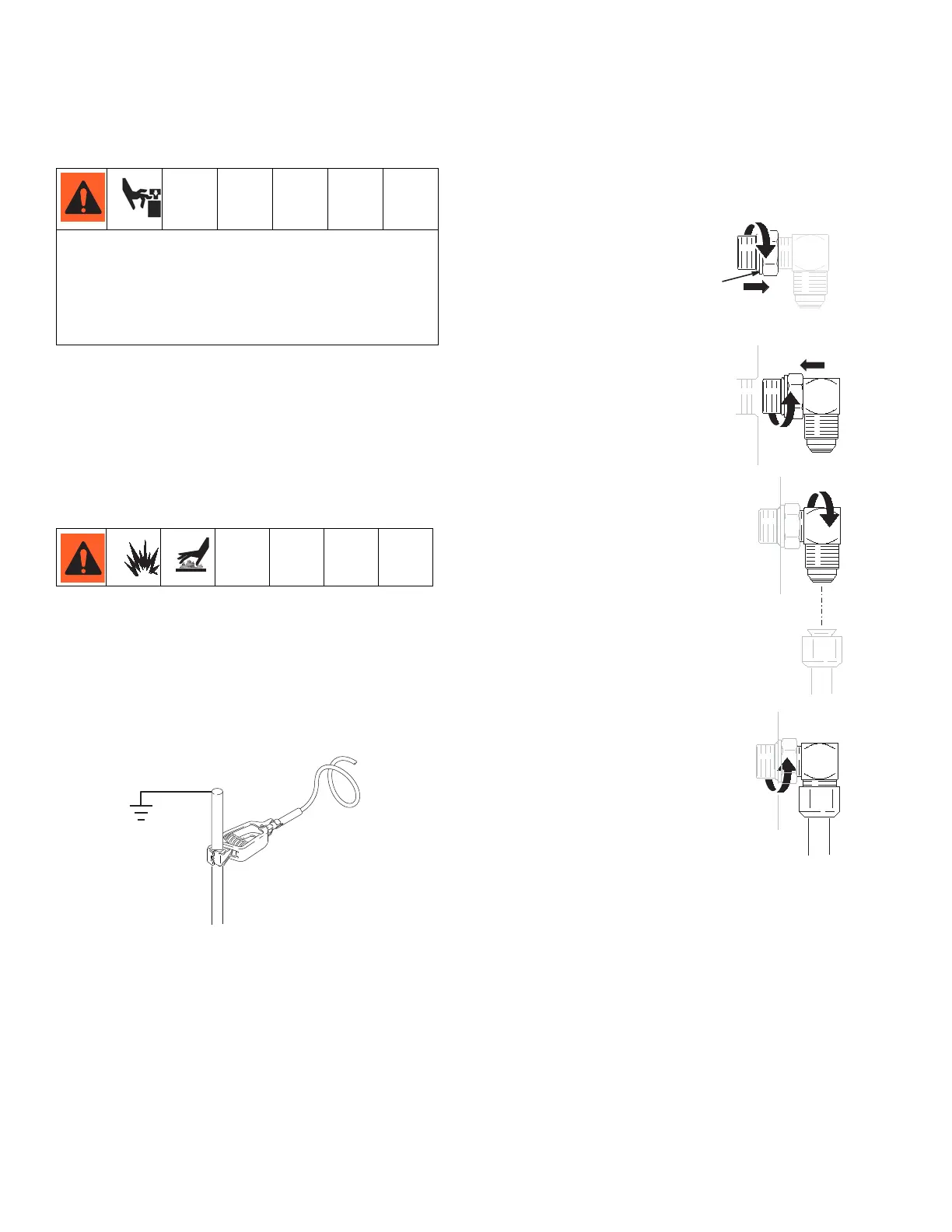

SAE O-Ring Installation

1 Unscrew lock nut to touch fitting.

2 Lubricate o-ring (A).

3 Screw in fitting hand tight.

4 Unscrew fitting until oriented

properly.

5 Tighten lock nut to indicated torque.

(Make sure washer is seated properly

without pinching o-ring).

To reduce risk of serious injury, do not touch

moving parts with fingers or tools while testing

repair. Shut off sprayer when repairing. Install all

covers, gaskets, screws and washers before

operating sprayer

Loading...

Loading...