To

reduce the risk of serious bodily injury, including

fluid injecfon, always follow the Pressure Relief

Procedure Warning on page 13 before checking,

adjusting, cleaning or shutting down the sprayer.

When

To

Flush

CAUTION

chance it could freeze. Push the water

out

with

min-

NEVER

leave water

in

the sprayer If there is the any

era1 spirits. Water frozen

in

the pressure control tube

prevents the sprayer from being started, and

causes serious damage to the pressure control.

1. New Sprayer.This sprayerwasfactorytested

in

light-

'

5,

Storage..

weight oi1,which was tell in to protect

the

pump parts. Wafer base paint: flush with water, then mineral spirits

Before using wafer-base paint, flush with mineral spir-

and leave the pump, hose and gun filled with mineral

soirit. Relieve oressure.

its, then soapy water, and then clean water.

Before

using

oil-basepainr, flush with mineral spirits.

Oil

base paint: flush with mineral spirits and leave the

pump, hose and gun filled with mineral spirit. Relieve

2. Changing Colors. Flush with a compatible solvent

pressure.

such as mineral spirits or water.

6.

Startup after storage.

__

..".

~~~~

r~-

~~~~~

3.

Changlngtromwater-basetooil-basepalnt.

Flush

with warm, soapy water, and then mineral spirits.

Before using wafer-base paint, flush

out

the mineral

snirits with soaov water. and then with clean water.

4.

Changlng from oil-base

to

water-base palnt. Flush

-8

~~~~

~I

I

with mineral spirits, then warm, soapy water, and then

When usingoil-basedpainf, flush

out

the mineral spir-

clean water.

its with the paint to be sprayed.

How

To

Flush

\A

1. Relieve pressure.

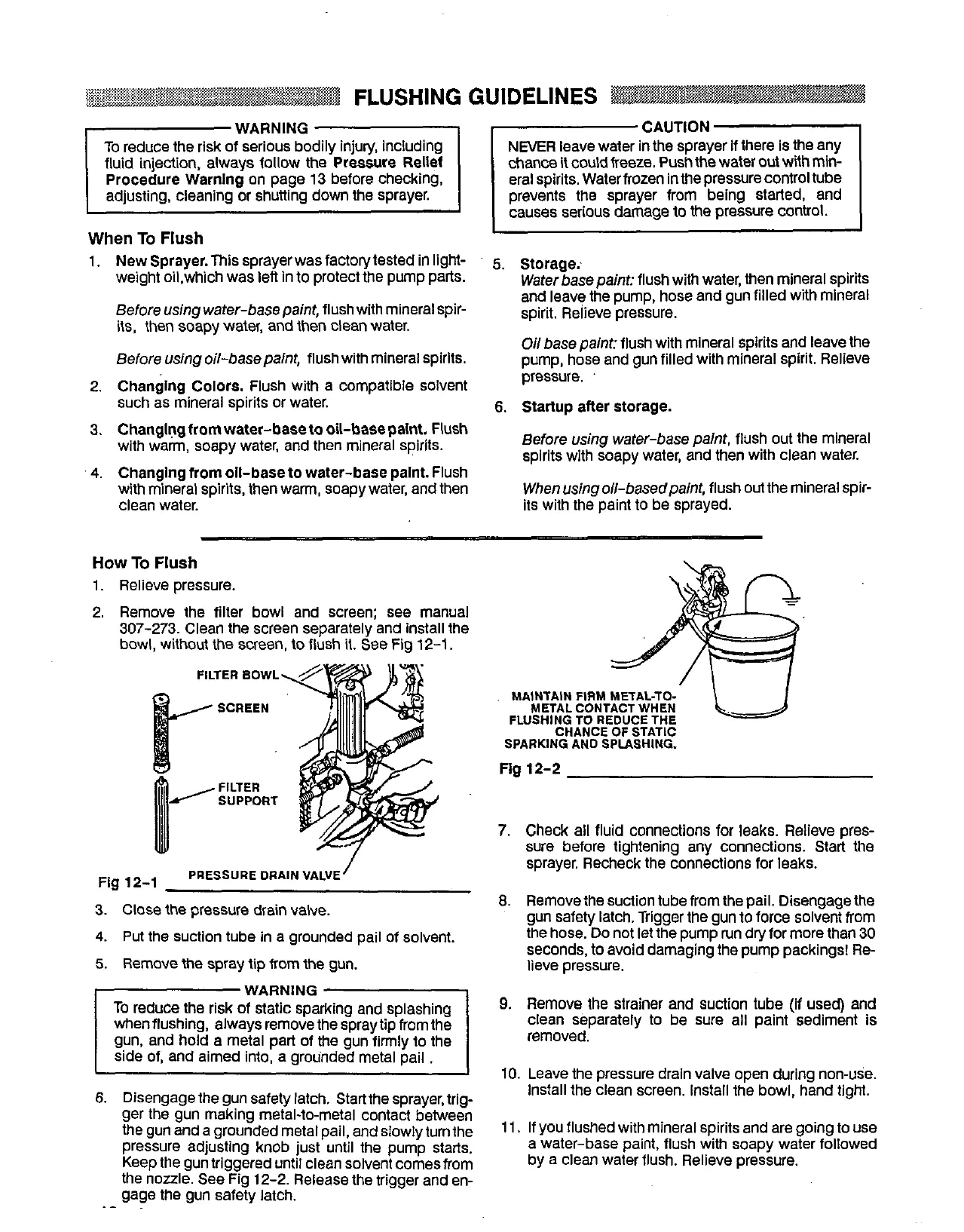

2. Remove the filter bowl and screen:

see

manual

307-273. Clean the screen separately and install the

bowl, without the screen, to flush it.

See

Fig 12-1.

FILTER

BOWL

SCREEN

FILTER

SUPPORT

Fig

12-1

3. Close the pressure drain valve.

4.

PLlt

the suction tube in a grounded pail of solvent.

5.

Remove the spray

tip

from

the

gun.

PRESSURE

DRAIN

VALVE'

WARNING

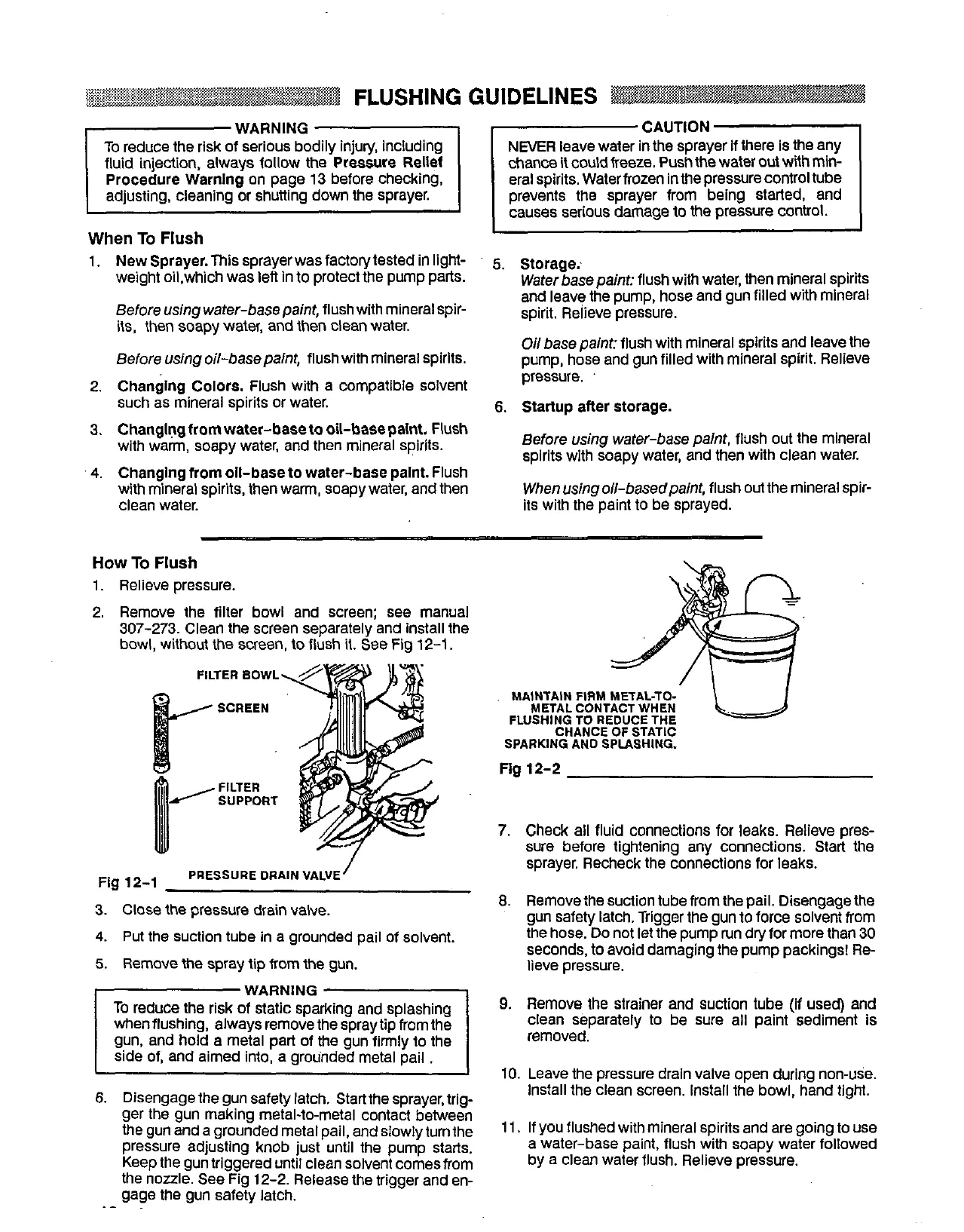

6.

Disengage the gun safety latch. Start the sprayer, trig-

ger the gun making metal-to-metal contact between

the gun and a grounded metal pail, and slowly turnthe

pressure adjusting knob just until the pump starts.

the nozzle.

See

Fig 12-2. Release the trigger and en-

Keep

the gun triggered until clean solvent comes from

gage the gun safety latch.

._

MAINTAIN

FIRM

METAL-TO-

FLUSHING

TO

REDUCE THE

METAL CONTACT WHEN

CHANCE OF STATIC

SPARKING AND SPLASHING.

Flg

12-2

7.

Check all fluid connections for leaks. Relieve pres-

sure before tightening any connections. Start the

sprayer. Recheck the connections for leaks.

8.

Removethe suction tube from the pail. Disengage the

the hose.

Do

not let the pump run dry for more than

30

gun safety latch. Trigger the gun to force solvent from

seconds, to avoid damaging the pump packings!

Re-

lieve pressure.

9.

Remove the strainer and suction tube (if

used)

and

clean separately to be sure all paint sediment is

removed.

10. Leave the pressure drain valve open during non-use.

Install the clean screen. Install the bowl, hand tight.

11.

If you flushed with mineral spirits and are going to

use

a water-base paint, flush with soapy water followed

by a clean water flush. Relieve pressure.

Loading...

Loading...