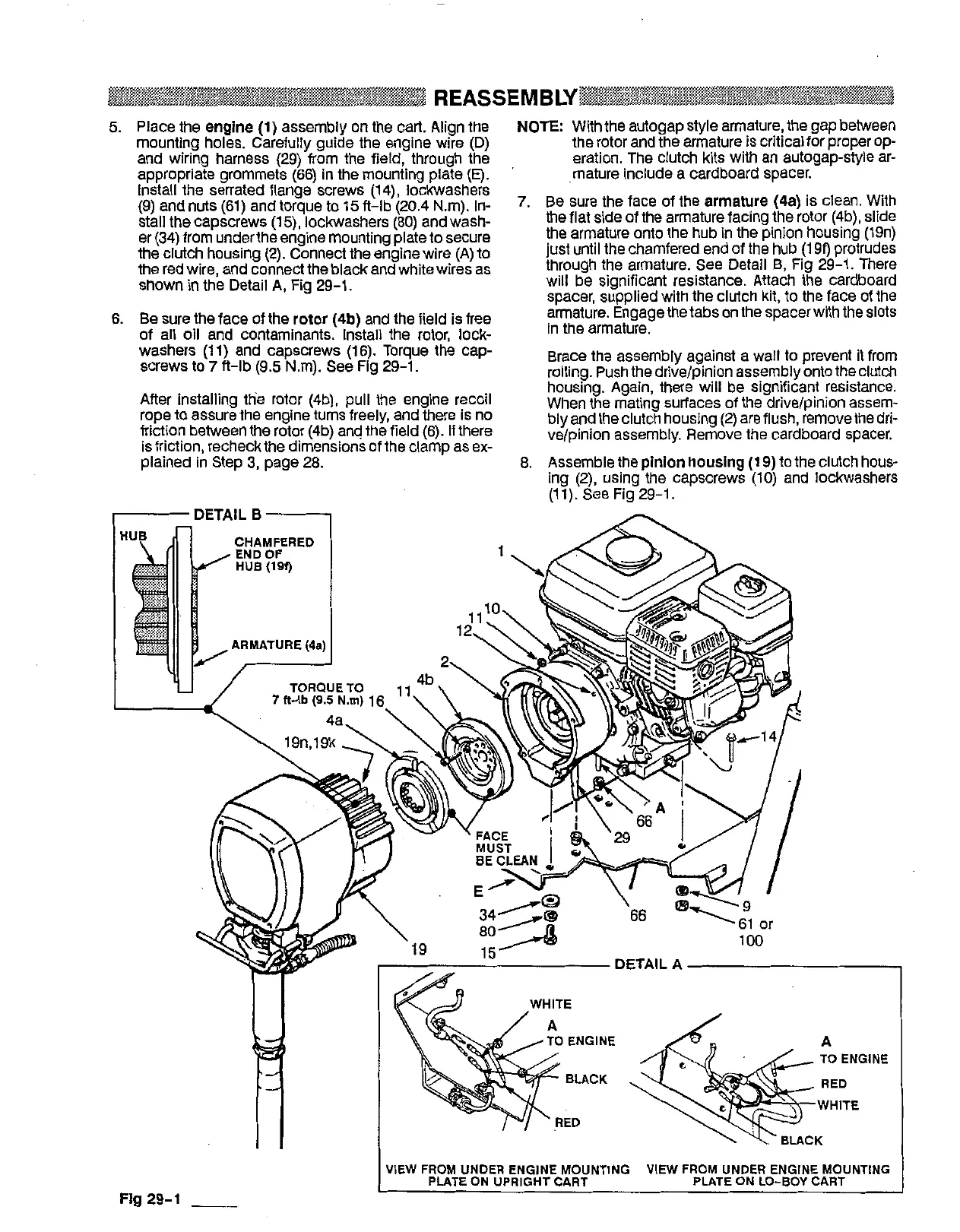

5.

Place the

engine

(1)

assembly on the cart. Align the

mounting holes. Carefully guide the engine wire (D)

and wiring harness (29) from the field, through the

appropriate grommets (66) in the mounting plate

(E).

Install the serrated flange screws (14), lockwashers

(9) and nuts (61) and torque to 15 fl-lb (20.4 Nm). In-

stall the capscrews (15), lockwashers (80) and wash-

er (34) from underthe engine mounting plate to secure

the clutch housing (2). Connect the enaine wire

IAl

to

the red wire, and connect the black aniwhite wiks'as

shown

in

the Detail

A,

Fig 29-1,

6.

Be

sure the face of the

rotor (4b)

and the field is free

washers (11) and capscrews (16). Torque the cap-

of all oil and contaminants. Install the rotor, lock-

screws to

7

fl-lb

(9.5

Nm).

See

Fig 29-1.

After installing ttie rotor (4b), pull the engine recoil

rope to assure the engine turns freely, and there

is

no

friction between the rotor

(4b)

and the field

(6).

If there

plained In Step

3,

page 28.

Is

friction, recheck the dimensions of the clamp as ex-

I

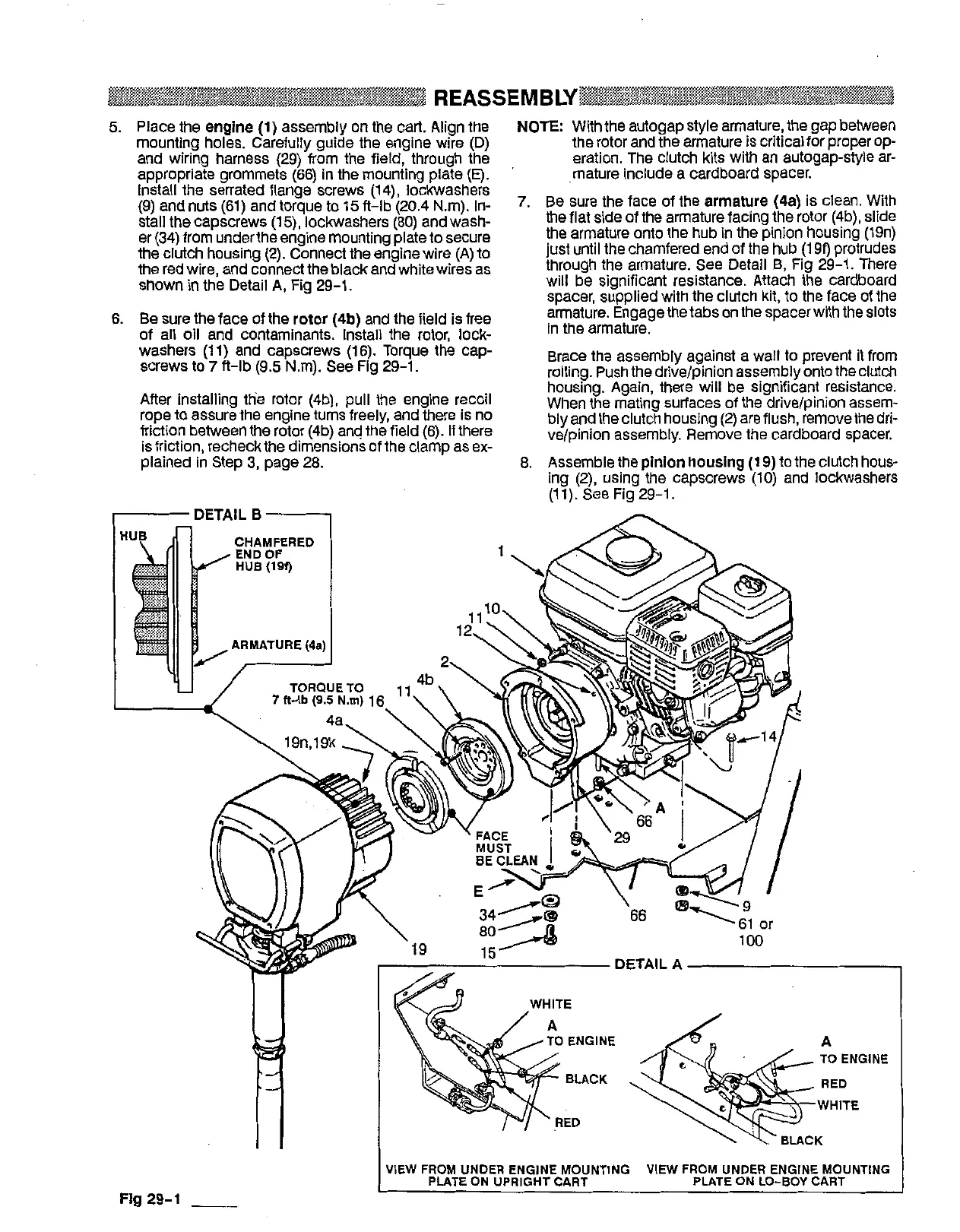

DETAIL B

-

NOTE:

With the autogap style armature, the gap between

the rotor and the armature is critical for proper op-

eration. The clutch kits with an autogap-style ar-

mature include a cardboard spacer.

7.

Be

sure the face of the

armature (48)

is clean. With

the flat side of the armature facing the rotor (4b), slide

the armature onto the hub in the pinion housing (19n)

just until the chamfered end of the hub (199 protrudes

through the armature.

See

Detail

B,

Fig 29-1. There

will be significant resistance. Attach the cardboard

spacer, supplied with the clutch kit, to the face of the

armature. Engage the tabson the spacerwith the slots

in the armature.

rolling. Push the drivdpinion assembly onto theclutch

Brace the assembly against a wall to prevent it from

When the mating surfaces of the drivelpinion assem-

housing. Again, there will be Significant resistance,

ve/pinion assembly. Remove the cardboard spacer.

bly and the clutch housing (2) are flush, remove the dri-

8. Assemble the plnlon housing

(1

9) to the clutch hous-

ing

(Z), using the capscrews (10) and lockwashers

(1 1). See Fig 29-1.

Flg 29-1

__

VIEW

FROM

UNDER ENGINE MOUNTING

VIEW

FROM

UNDER ENGINE MOUNTING

PLATE

ON

UPRIGHT CART PLATE ON

LO-BOY

CART

Loading...

Loading...