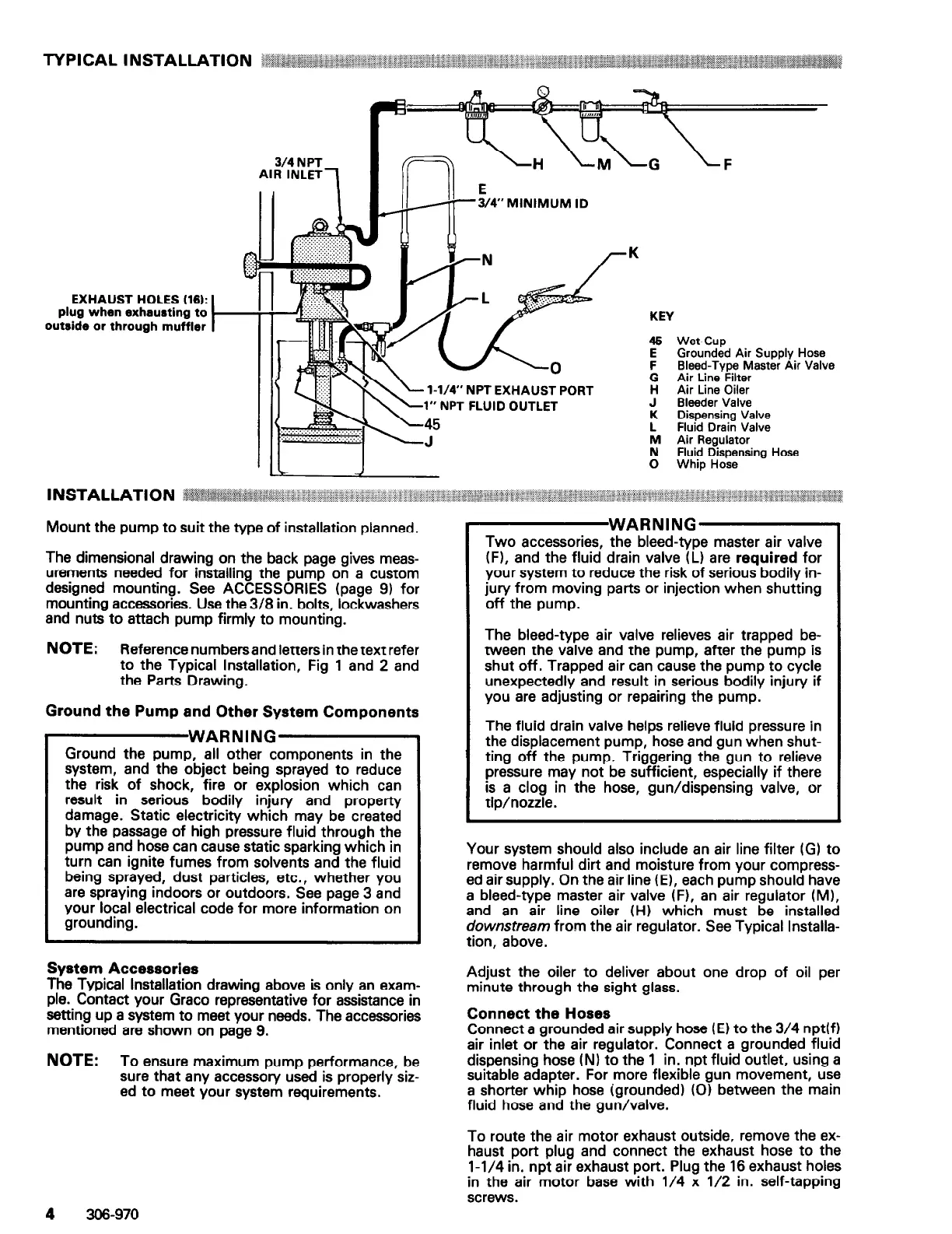

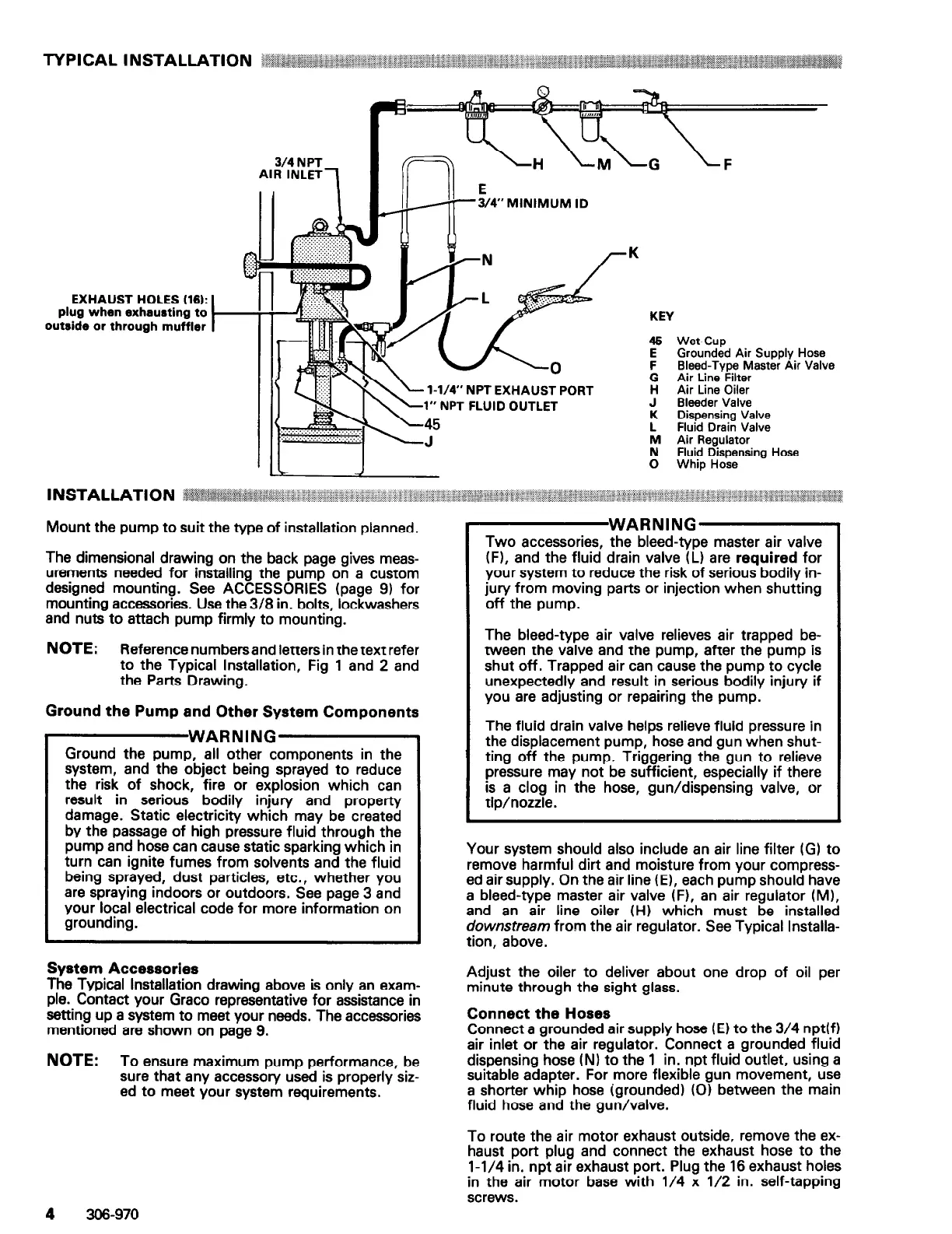

3/4” MINIMUM ID

EXHAUST HOLES (16):

plug when exhausting to

outside or through muffler

0

1-W” NPT

EXHAUST PORT

r FLUID

OUTLET

9’Ei%l Air Supply Hose

F Bleed-Type Master Air Valve

G Air Line Filter

H Air Line Oiler

J Bleeder Valve

K Dispensing Valve

L Fluid Drain Valve

M Air Regulator

N Fluid Dispensing Hose

0 Whip Hose

The dimensional drawing on the back page gives meas-

urements needed for installing the pump on a custom

designed mounting. See ACCESSORIES (page 9) for

mounting accessories. Use the 3/8 in. bolts, lockwashers

and nuts to attach pump firmly to mounting.

(F), and the fluid drain valve (L) are required for

your system to reduce the risk of serious bodily in-

jury from moving parts or injection when shutting

off the pump.

NOTE: Reference number-sand letters in the text refer

to the Typical Installation, Fig 1 and 2 and

the Parts Drawing.

Ground the Pump and Other System Components

WARNING

Ground the pump, all other components in the

system, and the object being sprayed to reduce

the risk of shock, fire or explosion which can

result in serious bodily injury and property

damage. Static electricity which may be created

by the passage of high pressure fluid through the

pump and hose can cause static sparking which in

turn can ignite fumes from solvents and the fluid

being sprayed, dust particles, etc., whether you

are spraying indoors or outdoors. See page 3 and

your local electrical code for more information on

grounding.

The bleed-type air valve relieves air trapped be-

tween the valve and the pump, after the pump is

shut off. Trapped air can cause the pump to cycle

unexpectedly and result in serious bodily injury if

you are adjusting or repairing the pump.

The fluid drain valve helps relieve fluid pressure in

the displacement pump, hose and gun when shut-

ting off the pump. Triggering the gun to relieve

pressure may not be sufficient, especially if there

is a clog in the hose, gun/dispensing valve, or

tip/nozzle.

Your system should also include an air line filter (G) to

remove harmful dirt and moisture from your compress-

ed air supply. On the air line (El, each pump should have

a bleed-type master air valve (F), an air regulator (MI,

and an air line oiler (HI which must be installed

downstream from the air regulator. See Typical Installa-

tion, above.

System Accessories

The Typical Installation drawing above is only an exam-

ple. Contact your Grace representative for assistance in

setting up a system to meet your needs. The accessories

mentioned are shown on page 9.

NOTE:

To ensure maximum pump performance, be

sure that any accessory used is properly siz-

ed to meet your system requirements.

4

306-970

Adjust the oiler to deliver about one drop of oil per

minute through the sight glass.

Connect the Hoses

Connect a grounded air supply hose (El to the 3/4 npt(f)

air inlet or the air regulator. Connect a grounded fluid

dispensing hose (N) to the 1 in. npt fluid outlet, using a

suitable adapter. For more flexible gun movement, use

a shorter whip hose (grounded) (0) between the main

fluid hose and the gun/valve.

To route the air motor exhaust outside, remove the ex-

haust port plug and connect the exhaust hose to the

l-1/4 in. npt air exhaust port. Plug the 16 exhaust holes

in the air motor base with l/4 x l/2 in. self-tapping

screws.

Loading...

Loading...