Repair/Parts

Husky

®

1050 Air-Operated

Diaphragm Pump

313435H

ENG

1-inch pump with modular air valve for fluid transfer applications.

For professional use only.

See page 3 for model information, including approvals.

125 psi (0.86 MPa, 8.6 bar) Maximum Fluid Working Pressure

125 psi (0.86 MPa, 8.6 bar) Maximum Air Input Pressure

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

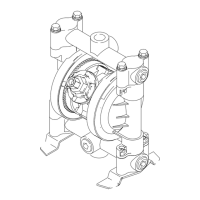

1050S Stainless Steel

1050H Hastelloy

ti14342a

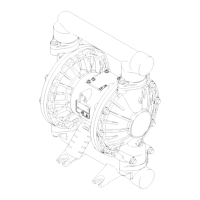

1050A Aluminum

ti13946a

Center

Flange

ti13844a

ti13843a

End

Flange

1050P Polypropylene

1050C Conductive

Polypropylene

1050F PVDF

Patents Pending

0359