Operation

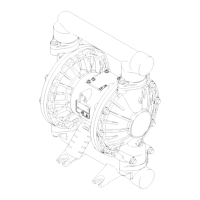

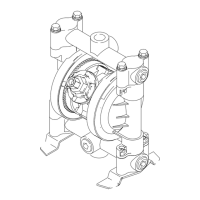

Husky™ Husky™

Husky™

2200 2200

2200

Air Air

Air

- -

-

Operated Operated

Operated

Diaphragm Diaphragm

Diaphragm

Pump Pump

Pump

3A2578E

EN

Polypropylene Polypropylene

Polypropylene

and and

and

PVDF PVDF

PVDF

pumps pumps

pumps

for for

for

uid uid

uid

transfer transfer

transfer

applications, applications,

applications,

including including

including

high high

high

viscosity viscosity

viscosity

materials. materials.

materials.

For For

For

professional professional

professional

use use

use

only. only.

only.

Not Not

Not

for for

for

use use

use

in in

in

European European

European

explosive explosive

explosive

atmosphere atmosphere

atmosphere

locations. locations.

locations.

Important Important

Important

Safety Safety

Safety

Instructions Instructions

Instructions

Readallwarningsandinstructionsinthismanualandinyour

Repair/Partsmanual.Save Save

Save

these these

these

instructions. instructions.

instructions.

Maximum Working Pressure: 125 psi

(0.86 MPa, 8.6 bar)

PROVENQUALITY.LEADINGTECHNOLOGY.