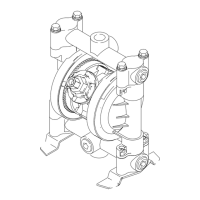

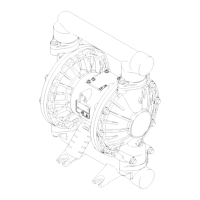

ACETAL AND POLYPROPYLENE

Husky™ 307 Air–Operated

Diaphragm Pumps

100 psi (0.7 MPa, 7 bar) Maximum Fluid Working Pressure

100 psi (0.7 MPa, 7 bar) Maximum Air Input Pressure

*Model No. D31 Acetal Pumps, Series E

*Model No. D32

Polypropylene Pumps, Series E

*Model No. D3A Acetal BSPT Pumps, Series E

*Model No. D3B Polypropylene BSPT Pumps, Series E

* To determine the Model No. for your pump and for additional models, refer to the Pump Matrix

on page 26.

Patent No.

US 5,240,390

US 5,280,808

Instructions–Parts List

308553AF

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

01428B