308553 23

Service

Diaphragm Repair

Tools Required

D Torque wrench

D One 7/16” (11 mm) and two 1/2” (13 mm)

socket wrenches

D Phillips screwdriver

D O-ring pick

D 13/32” EZY-OUT bearing extractor

D Rubber mallet

D Vise with soft jaws

Disassembly

NOTE: A Fluid Section Repair Kit is available. See

page 27 for the correct kit. Parts included in the kit are

marked with an asterisk, for example (401*). Use all

the parts in the kit for the best results.

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 11.

1. Relieve the pressure. Disconnect all hoses.

2. Remove the air valve from the pump (see page

16).

3. Remove the manifolds (102) and disassemble the

ball check valves as explained on page 21. Always

replace the o-rings (108) with new ones.

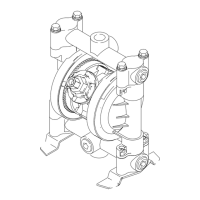

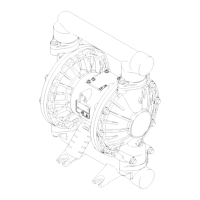

4. Using a 7/16” socket wrench, remove the clamp

nuts (113) and the grounding strip (112). Loosen

the clamps (111) and slip them over the housing

(1). Pull the covers (101) off the pump, then

remove the clamps from the housing. See the

Detail in Fig. 16.

5. Using a 1/2” socket wrench on both outer dia-

phragm plates (103), unscrew one plate from the

diaphragm shaft (23). Remove one diaphragm

(401), inner diaphragm plate (118), and o-ring

(404). Pull the opposite diaphragm assembly and

the diaphragm shaft out of the pump housing (1).

See Fig. 16. Clamp the shaft in a vise with soft

jaws and unscrew the outer plate (103), then

disassemble the remaining diaphragm assembly.

6. Inspect the diaphragm shaft (23}) for wear or

scratches. If it is damaged, check the bearings

(31}) also. Replace parts as needed. To remove

the bearings, place a 13/32 EZY-OUT in a vise.

Position the pump housing (1) over the EZY-OUT

(see Fig. 16). Turn the housing in the direction

shown by the arrows to remove the bearing.

7. Hook the shaft seals (30}) with an o-ring pick and

pull them out of the housing (1).

8. Clean all parts and inspect for wear or damage.

Replace parts as needed.

Loading...

Loading...