24 308553

Service

Reassembly

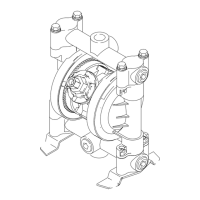

1. Install the shaft seals (30}) in the housing (1).

Using a rubber mallet, carefully drive the bearings

(31}) flush into the housing so the holes face out.

See Fig. 16.

2. Grease the diaphragm shaft (23}) and slide it into

the housing (1). Install the o-rings (404*) in the

grooves of the housing.

3. Assemble the inner diaphragm plates (118), dia-

phragms (401*), and outer diaphragm plates (103)

as shown in Fig. 16. Apply medium-strength (blue)

LoctiteR or equivalent to the threads of the fluid-

side plates (103), and torque the plates to 75 to 85

in-lb (8.5 to 9.6 NSm) at 100 rpm maximum using a

1/2-in. socket wrench. Do not over-torque. These

parts must be assembled correctly.

CAUTION

Do not over-torque the outer diaphragm plates

(103). Doing so will damage the hex heads.

4. When installing the covers (101), slip the clamps

(111) over the housing (1) before positioning the

covers. See the Detail in Fig. 16. Engage the

notches in the covers with the locator tabs on the

housing, then position the clamps over both parts.

The clamp bolts should be on the air valve side of

the housing, and pointing down toward the bottom

of the pump. Install the grounding strip on the

bolts. Apply thread lubricant to the bolts, then

install the clamp nuts (113). Using a 7/16” socket

wrench, torque the nuts to 50 to 60 in-lb (5.6 to 6.8

NSm). See Torque Sequence, page 32.

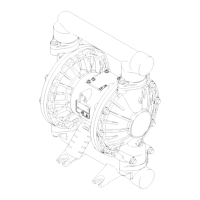

5. Reassemble the ball check valves and manifolds

as explained on page 21. Always install new

o-rings (108*), and make sure they are properly

seated.

6. Reinstall the air valve, using the six mounting

screws (15). See Fig. 10.

Loading...

Loading...