Instructions - Parts List

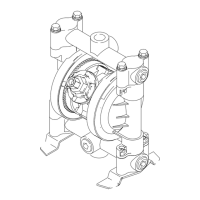

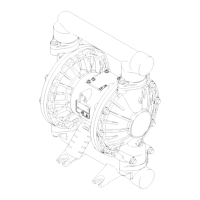

ACETAL, POLYPROPYLENE, AND PVDF

Husky™ 1040 Air-Operated

Diaphragm Pumps

308443ZAE

EN

1–inch AODD pump for fluid transfer applications. For professional use only.

Not approved to European explosive atmosphere requirements.

See Models on page 2 for a list of pump models and descriptions.

120 psi (0.8 MPa, 8 bar) Maximum Fluid Working Pressure

120 psi (0.8 MPa, 8 bar) Maximum Air Input Pressure

Important Safety Instructions

Read all warnings and instructions in the manual.

Save these instructions.