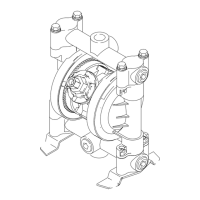

Air–Operated

Diaphragm Pumps

For fluid transfer applications. For professional use only.

Only models marked with (*) are approved for use in European explosive atmosphere

locations.

100 psi (0.7 MPa, 7 bar) Maximum Fluid Working Pressure

100 psi (0.7 MPa, 7 bar) Maximum Air Input Pressure

ACETAL, POLYPROPYLENE, AND PVDF

Huskyt 515

Model No. D 5 1 _ _ _ Acetal NPT Pumps*

Model No. D 5 2 _ _ _ Polypropylene Pumps

Model No. D 5 5 _ _ _ PVDF NPT Pumps

Model No. D 5 A _ _ _ Acetal BSPT Pumps*

Model No. D 5 B _ _ _ Polypropylene BSPT Pumps

Model No. D 5 E _ _ _ PVDF BSPT Pumps

For Additional Models, see Table of Contents

ALUMINUM AND STAINLESS STEEL*

Huskyt 716

Model No. D 5 3 _ _ _ Aluminum NPT Pumps

Model No. D 5 4 _ _ _ Stainless Steel NPT Pumps

Model No. D 5 C _ _ _ Aluminum BSPT Pumps

Model No. D 5 D _ _ _ Stainless Steel BSPT Pumps

For Additional Models, see Table of Contents

Patents Pending

Instructions

9246A

Husky 515

Husky 716

9065A

*These models are certified.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

Refer to the Pump Matrix on page 20 to determine

the model number of your pump.

308981ZAA

EN