Instructions – Parts List

POLYPROPYLENE AND PVDF

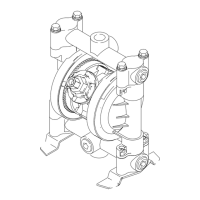

Huskyt 1590 Air-Operated

Diaphragm Pumps

1.5–inch AODD pump for fluid transfer applications. For professional

use only.

Not approved to European explosive atmosphere requirements.

See Models on page 2 for a list of pump models and descriptions.

120 psi (0.84 MPa, 8.4 bar) Maximum Fluid Working Pressure

120 psi (0.84 MPa, 8.4 bar) Maximum Air Input Pressure

308549ZAC

EN

Important Safety Instructions

Read all warnings and instructions in

this manual. Save these instructions.

04700B