DISPLACEMENT PUMP SERVICE

Before you Start:

A. To reduce downtime, be sure you have all necessary re-

pair parts available. Recommended “tool box” spare

parts are listed in the parts list with an asterisk (“1.

6

B. Packing repair kit 210539 is available (see page 10).

If you have a repair kit, use all the new parts for the

best results. Parts included in the kit are marked with

a double asterisk, for example (28”“).

C. When cleaning parts, use a compatible solvent. In-

spect parts for wear or damage and replace as

necessary. Scoring or irregular surfaces on the

displacement rod (46) or smooth inner surface of the

displacement cylinder (27) causes premature packing

wear and leaking. Check these parts by rubbing a

finger on the surface or holding them up to the light

at a slight angle.

D. Use light, water-proof grease whenever grease is

mentioned.

Repair Procedure

1. Solvent flush the fluid from the pump if possible.

Follow the Pressure Relief Procedure on page 6.

Stop the pump at the bottom of its stroke.

2. Disconnect the hoses from the displacement pump.

Remove the pump from its mounting, and clamp it

in a vise.

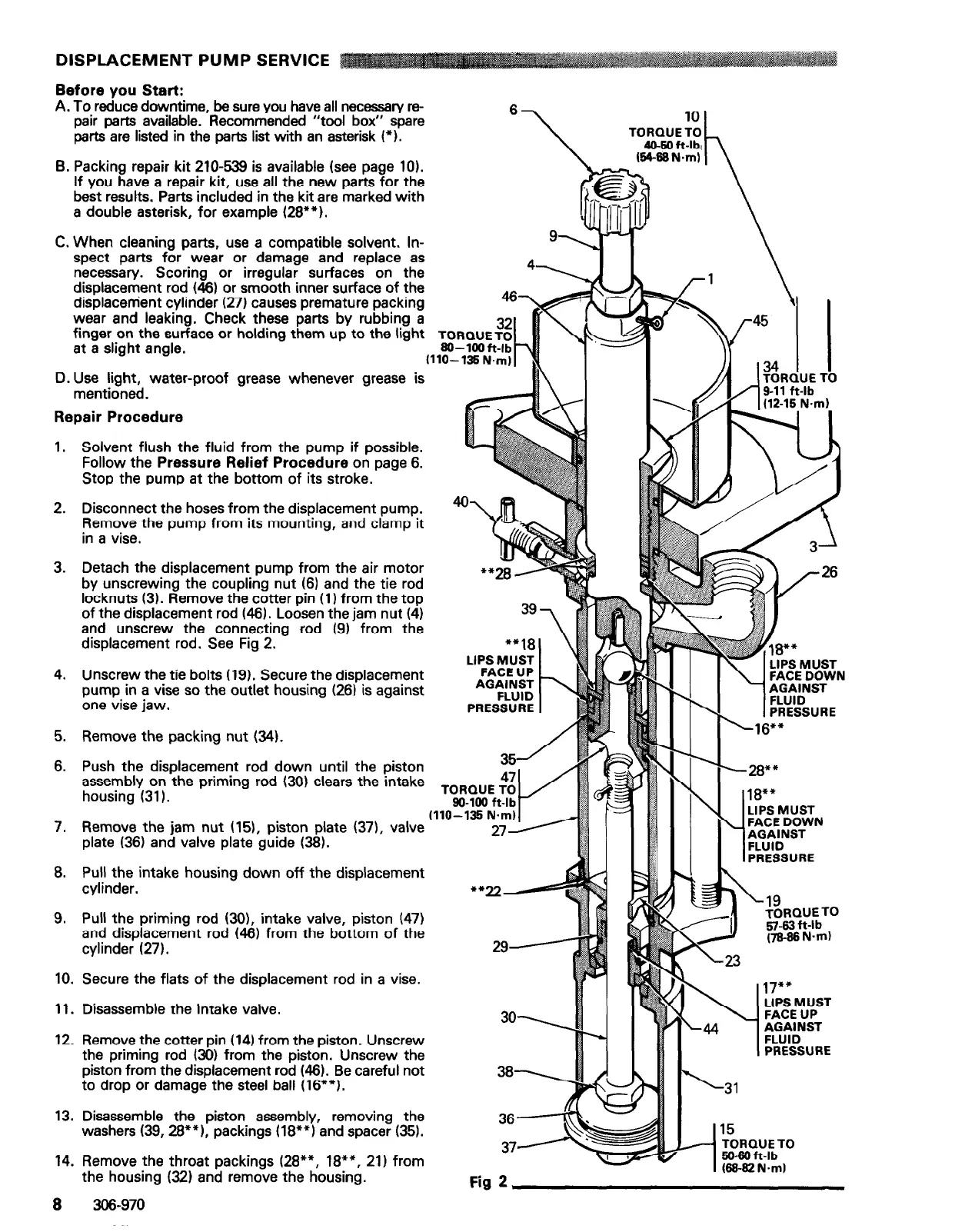

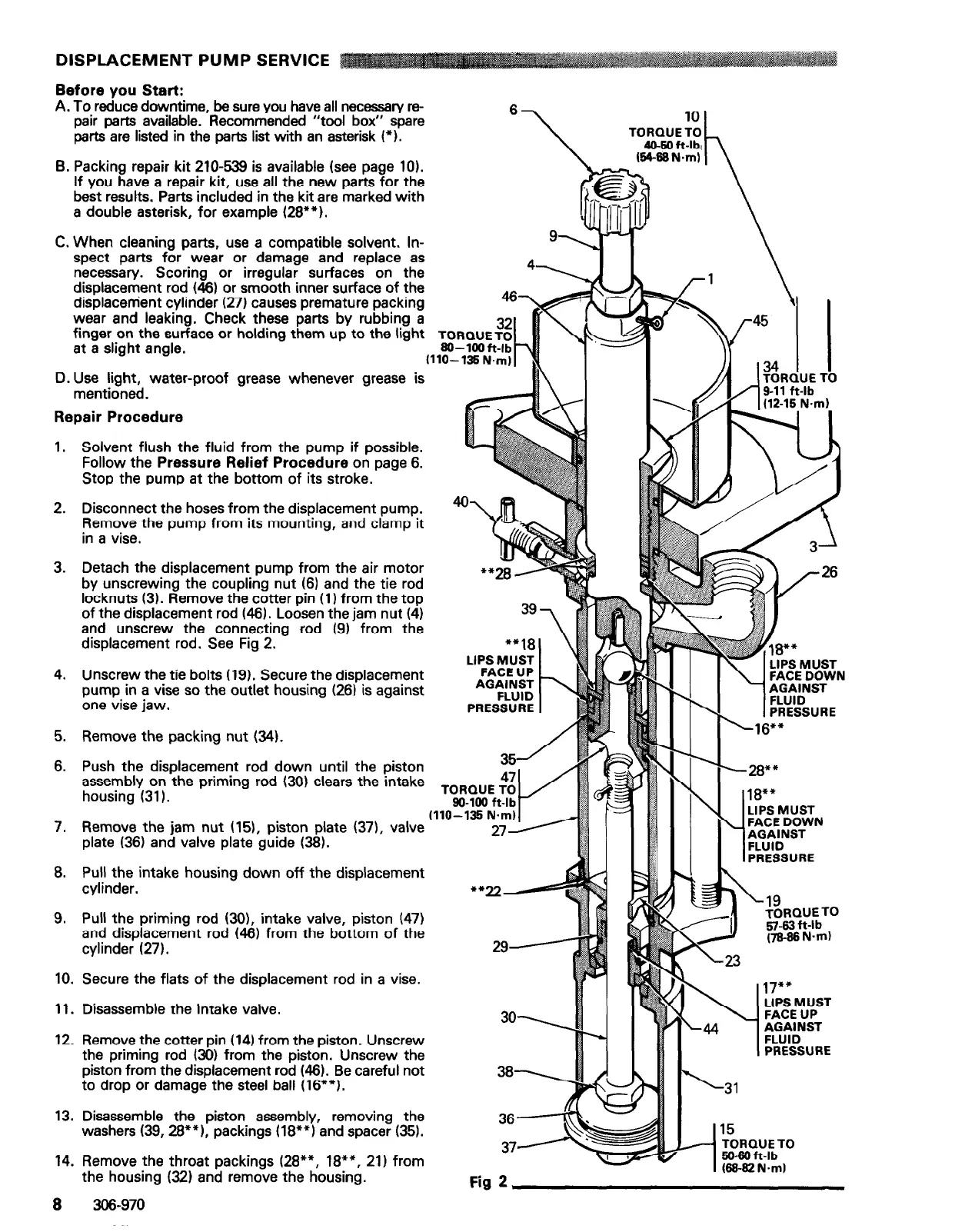

3. Detach the displacement pump from the air motor

by unscrewing the coupling nut (6) and the tie rod

locknuts (3). Remove the cotter pin (1) from the top

of the displacement rod (46). Loosen the jam nut (4)

and unscrew the connecting rod (9) from the

displacement rod. See Fig 2.

4. Unscrew the tie bolts (19). Secure the displacement

pump in a vise so the outlet housing (26) is against

one vise jaw.

5. Remove the packing nut (34).

6. Push the displacement rod down until the piston

assembly on the priming rod (30) clears the intake

housing (31).

39

7

“+18

LIPS MUST

FACE UP

AGAINST

FLUID

PRESSURE

TORQUE TO

(110-135 N.m)

7. Remove the jam nut (151, piston plate (371, valve

plate (36) and valve plate guide (38).

8. Pull the intake housing down off the displacement

cylinder.

9. Pull the priming rod (301, intake valve, piston (47)

and displacement rod (46) from the bottom of the

cylinder (27).

10. Secure the flats of the displacement rod in a vise.

**=A

29-

11. Disassemble the intake valve.

so\

12. Remove the cotter pin (14) from the piston. Unscrew

the priming rod (30) from the piston. Unscrew the

piston from the displacement rod (46). Be careful not

to drop or damage the steel ball (16”“).

38-

13. Disassemble the piston assembly, removing the

washers (39,28**1, packings (18”“) and spacer (351.

36-

37A

14. Remove the throat packings (28**, 18**, 21) from

. . . ,_^.

. . .

1

15

TORQUE TO

50-60 ft-lb

(W-S2 N.ml

\-19

TORQUE TO

R-63 ft-lb

(78-W N-m)

17**

WEMu;ST

AGAINST

FLUID

PRESSURE

the

hOuSIng

W;L) and remove the housing.

Fig 2

8 306-970

Loading...

Loading...