12 307-738

Maintenance

Thorough flushing and proper maintenance are

essential to keep the sprayer working properly

and

avoid costly damage to the sprayer or the ob

-

ject being sprayed.

Diaphragm Failure: Always replace the diaphragm

after

every 500 hours

of operation (once every 4 to 6

months). The diaphragm weakens with use. If the

diaphragm

ruptures, hydraulic oil and paint may mix,

damaging

the sprayer and/or the surface of the object

being

sprayed may be damaged.

Follow the Maintenance Intervals outlined below

.

CAUTION

Maintenance Intervals

Flushing Immediately

after each use.

Lubricate the intake valve.

Immediately after each use.

Tighten the paint pump

screws

and the inlet valve.

1.

After

the first 3 to 5 hours of

operation.

2. After the next 3 to 5 hours

of

operation.

3. Each 25 hours thereafter

(about weekly).

Check

or

change the hydrau

-

lic

oil.

1. Check the oil after each

use

of the sprayer

.

2.

Change the oil after the first

20

hours of operation.

3. Change the oil each 50

hours

thereafter (about twice

monthly).

Replace the diaphragm.

After every 190,000 liters of

paint

sprayed (4 to 6 months).

Flushing Procedure

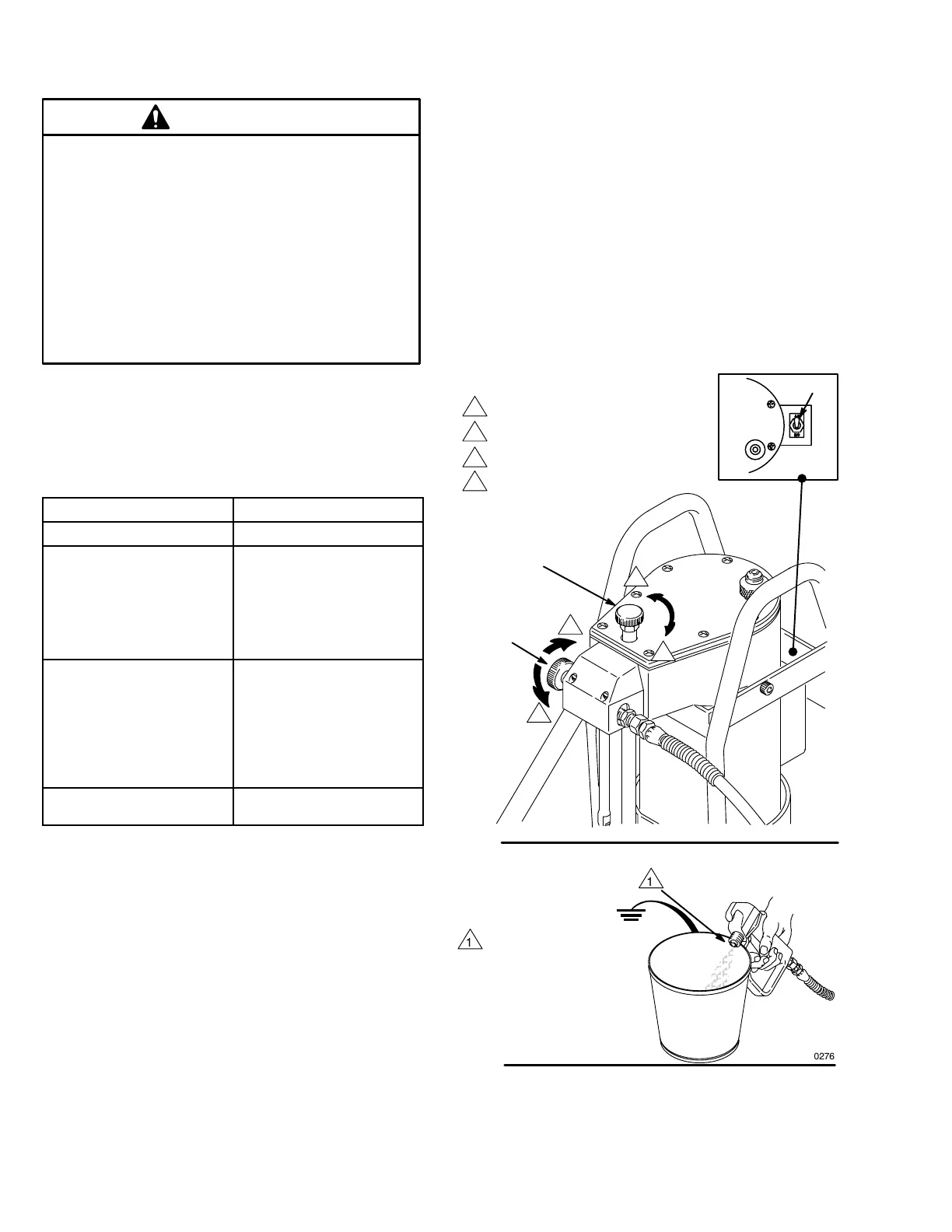

1. Shut off the sprayer. Lock the gun trigger safety le-

ver.

Open

the bypass valve (66) ONE turn

counter-

clockwise. Raise the paint pump just above the

paint

and turn on the sprayer to drain the paint. Now

turn

of

f the sprayer

. See Fig. 7.

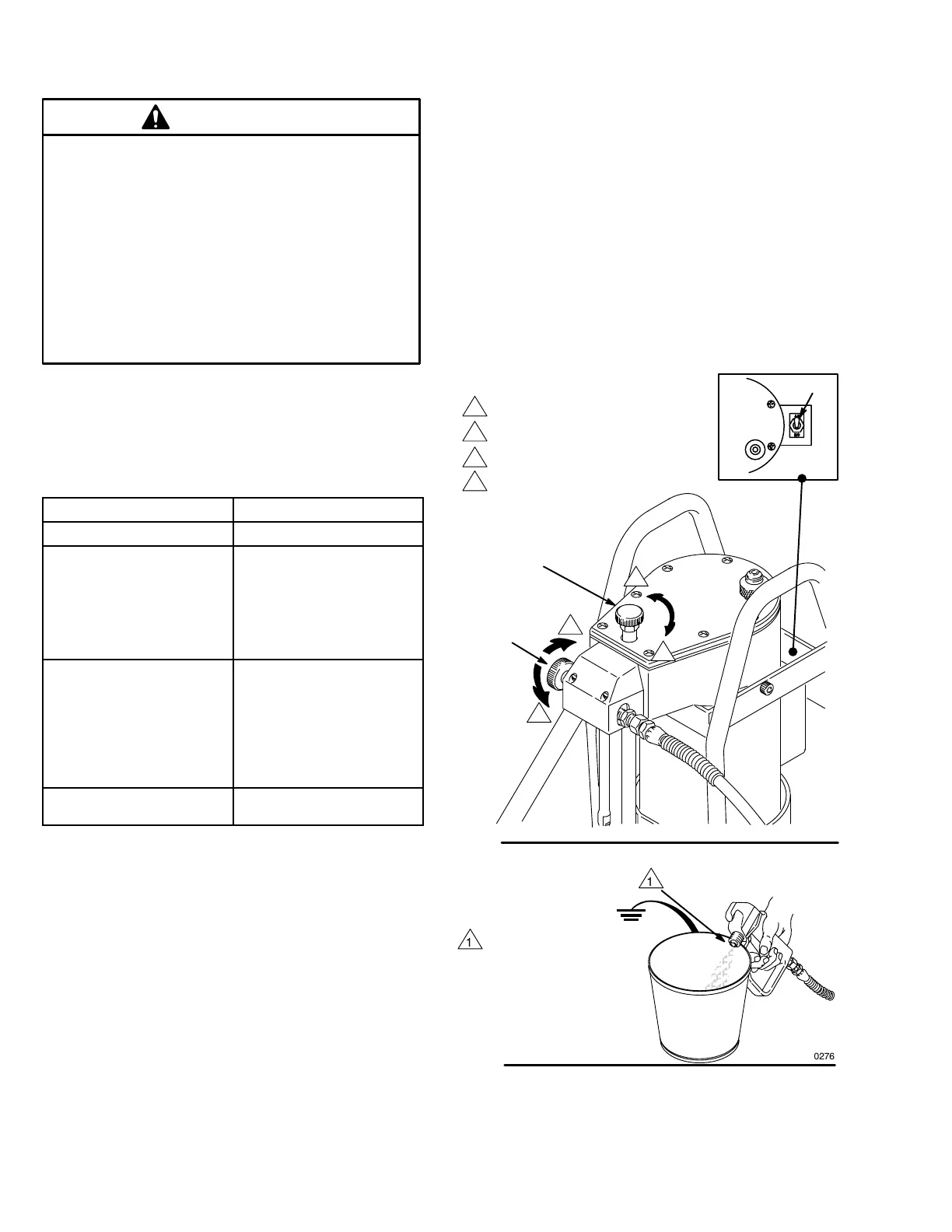

2. Place the paint pump in a grounded flushing pail of

solvent.

3. Check to be sure the trigger safety lever is locked.

Remove

the spray tip from the gun.

Unlock the safety

lever. Hold a metal part of the gun firmly to the side

of a grounded metal pail. Close the bypass valve

(66).

T

rigger

the gun into the pail. T

urn on the spray

-

er. Watch the side of the pail for solvent to appear .

Then

release the gun trigger

. T

urn of

f the sprayer

.

4. With

the bypass valve (66) closed, turn on the spray

-

er,

trigger the gun into the flushing pail and allow the

solvent

to circulate through the hose and gun for two

to

three minutes, using the lowest possible

pressure.

See

Fig.

8. Release the gun trigger and lock the safe

-

ty

lever

. T

urn of

f the sprayer

.

Fig. 7

Decrease

pressure

(counterclockwise).

Increase pressure (clockwise).

Open (counterclockwise).

Close (clockwise).

66

4

11

Maintain firm met

-

al–to–metal

contact

between

gun and

container

Fig.

8

Loading...

Loading...