307-738 9

Startup

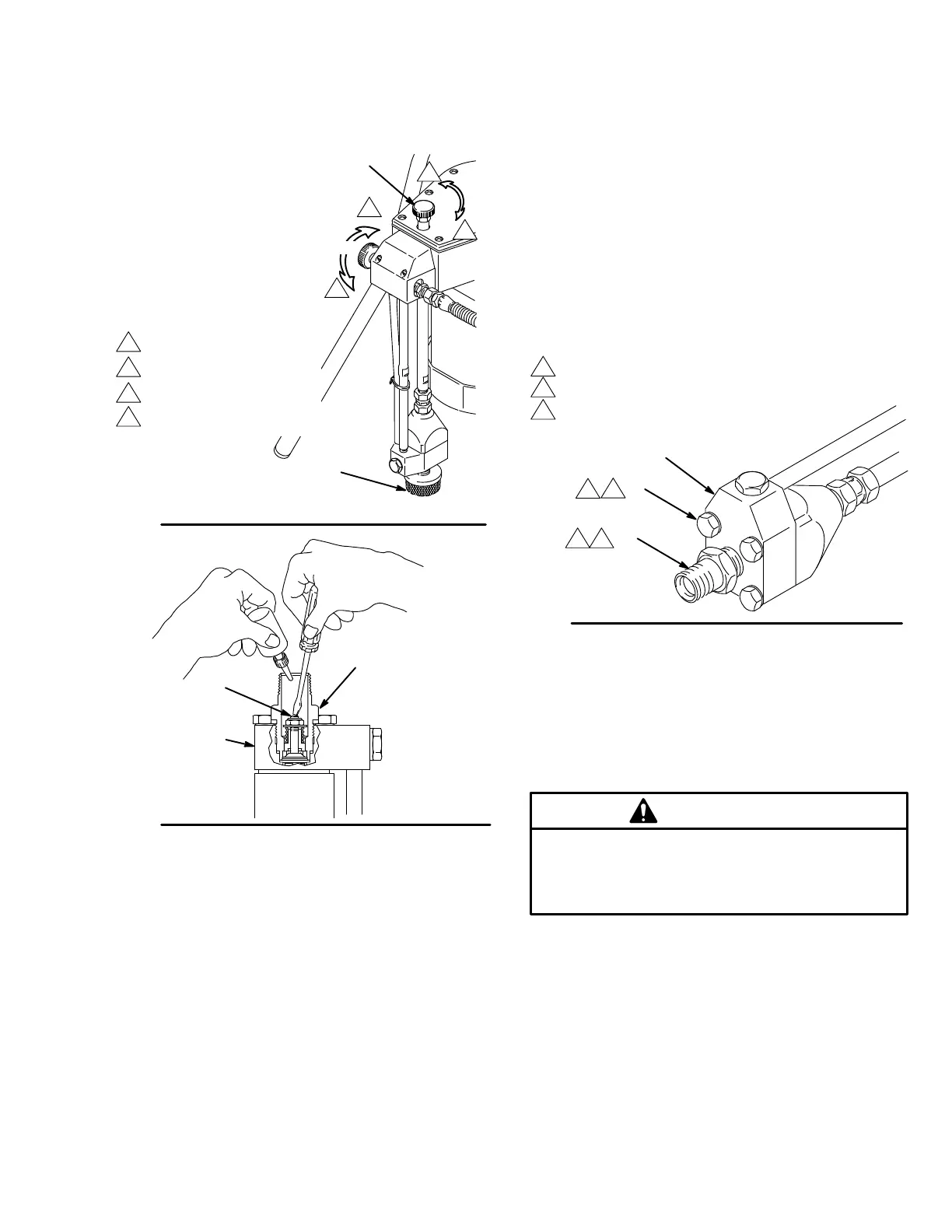

6. Turn the bypass valve (66) clockwise (finger tight)

to

close it; this allows the pump to build up pressure.

Fig.

3

Fig. 4

27

66

4

Decrease

pressure

(counterclockwise).

Increase pressure (clockwise).

Open (counterclockwise).

Close (clockwise).

22

26

A

7. Release the trigger safety lever and trigger the gun

onto

a piece of paper to check the spray pattern. Ad

-

just

the pressure setting to obtain the best atomiza

-

tion and spray pattern.

Always use the lowest

pressure necessary .

Excessive pressure cause

premature

tip wear and pump wear

.

NOTE: If

you cannot obtain a good spray pattern or ade

-

quate

atomization, your paint may be too thick. Thin the

paint

according to the manufacturer

’

s recommendations

until

you can get good atomization.

8. Whenever

you stop spraying, even for a moment,

al

-

ways

set

the trigger safety lever to prevent acciden

-

tally

trigger the gun.

9. Whenever you stop spraying for more than a mo-

ment, or if you must leave the sprayer unattended,

shut

it of

f and follow the

Pressure Relief Procedure

on

page 8.

NOTE: The

sprayer will not restart

if it was left pressur

-

ized

after shutting it off. Relieve pressure, then start

the

sprayer.

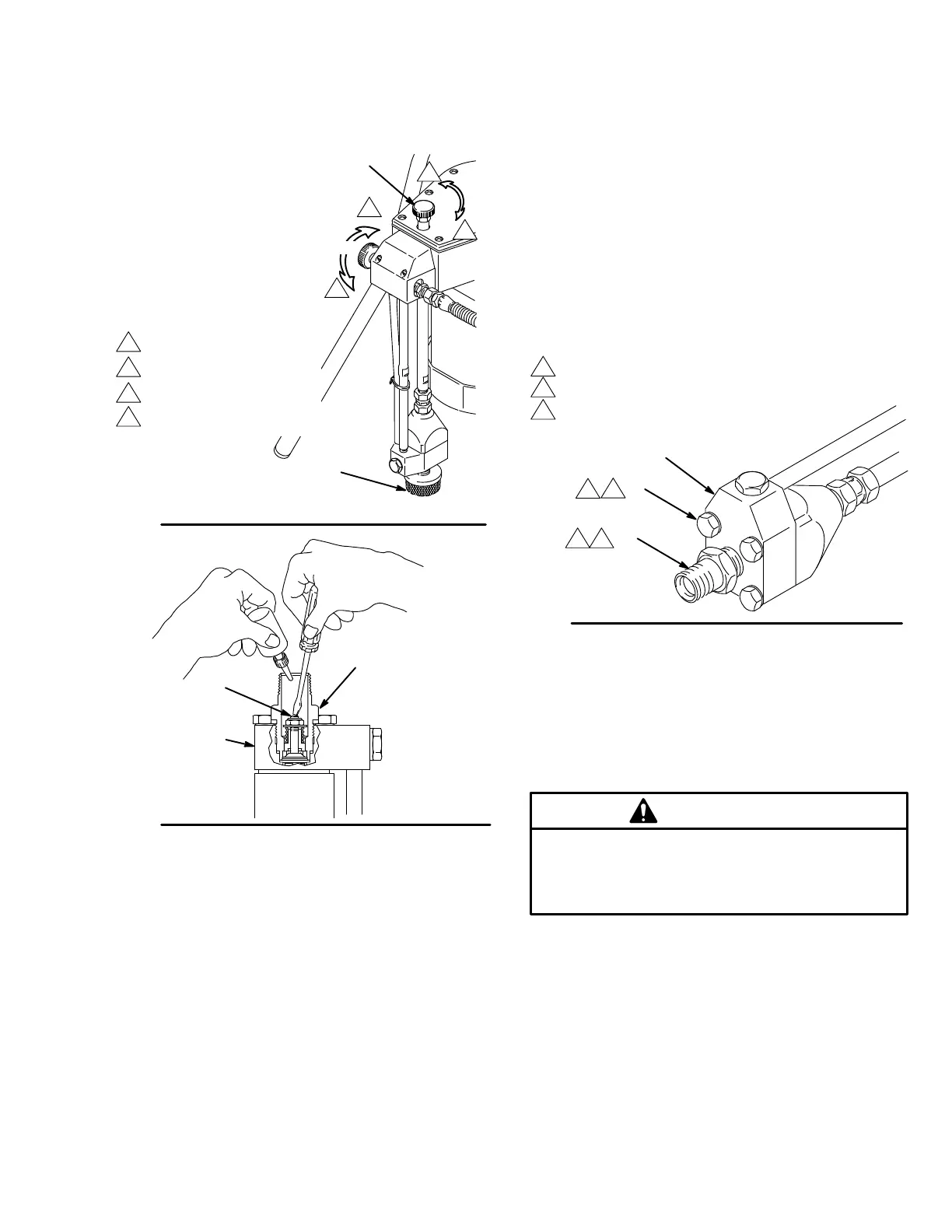

Fig. 5

Lubricate

the threads.

T

orque to 19–23 N.m.

T

orque to 36–41 N.m.

22

26

25

10.

After

the first 3 to 5 hours of operation

torque the

four

screws (25) on the bottom of the paint pump (22)

to

19–23 N.m. See Fig. 5.

11.

Also torque

the inlet valve (26) to 36–41 N.m.

CAUTION

Failure

to properly tighten the inlet valve and

screws

at

the intervals indicated will result in oil leaking from

the hydraulic system into the paint, and can cause

costly

damage to the sprayer

.

12.

Repeat

these torques

after another

3 to 5 hours of

operation,

and then after each 25 hours of operation

(about

weekly).

startup procedure continued on page 10

Loading...

Loading...