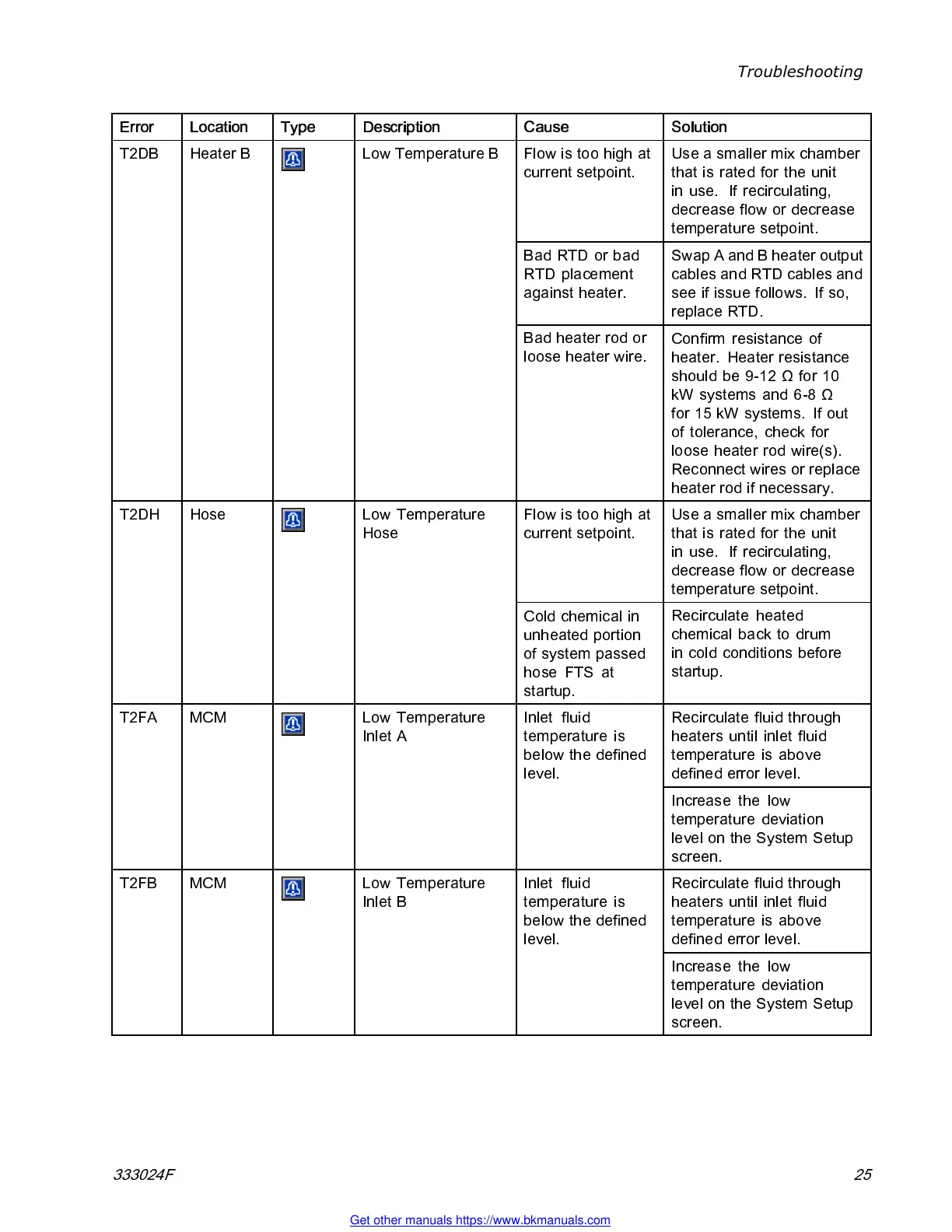

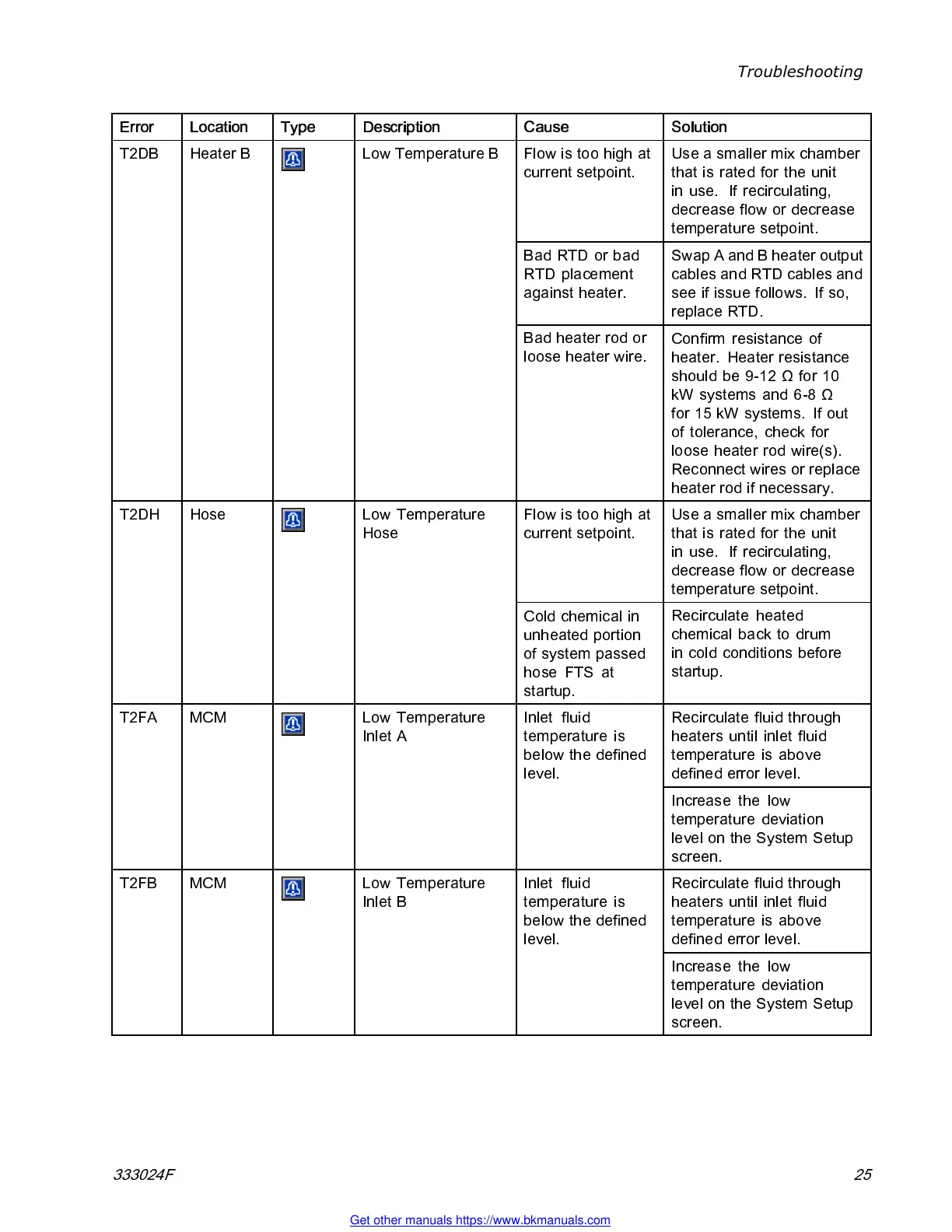

Troubleshooting

Error Location Type Description

Cause Solution

Flow is too high at

current setpoint.

Use a smaller mix chamber

that is rated for the unit

in use. If recirculating,

decrease flow or decrease

tempera ture setpoint.

Bad RTD or bad

RTD placement

against heater.

Swap A and B heater output

cables and RTD cables and

see if issue follows. If so,

replace RTD.

T2DB Heater B Lo w Tem perature B

Bad heater rod or

loose heater wire.

Confirm resistance of

heater. Heater resistance

shouldbe9-12Ωfor10

kW systems and 6-8 Ω

for 15 kW systems. If out

of tolerance, check for

loose h eater rod wire(s).

Reconnect wires or replace

heater rod if necessary.

Flow is too high at

current setpoint.

Use a smaller mix chamber

that is rated for the unit

in use. If recirculating,

decrease flow or decrease

tempera ture setpoint.

T2DH Hose Low Tem perature

Hose

Cold c hemical in

unheated portion

of system passed

hose FTS at

startup.

Recirculate heated

chem ical bac k to drum

in cold c ond itio ns b efo re

startup.

Recirculate fluid through

heaters until inlet fluid

tempera ture is above

defined error level.

T2FA

MCM

Low T emperature

Inlet A

Inlet fluid

temperature is

below the defined

level.

Increase the low

tempera ture deviati on

level on the System Setup

screen.

Recirculate fluid through

heaters until inlet fluid

tempera ture is above

defined error level.

T2FB MCM Low Temperature

Inlet B

Inlet fluid

temperature is

below the defined

level.

Increase the low

tempera ture deviati on

level on the System Setup

screen.

333024F 25

Get other manuals https://www.bkmanuals.com

Loading...

Loading...