Repair

Change Pump Lubricant

Check the condition of the ISO pump lubricant daily.

Change the lubric ant if it becom es a gel , its co lor

darkens , or it b ec ome s di lu ted wi th iso cy an ate .

Gel formation is due to moisture absorption by the

pump lubricant. The interval between changes

depends on the environment in which the equipment

is operating. The pump lubrication system min imizes

expos ure to mo is ture, b ut so me c ont ami nation i s s til l

possible.

Lubricant dis coloration is due to conti nual see page of

small amounts of isocyanate past the pump packings

during operation. If the packings are operating

properly, lub ricant replac em ent du e to di sc olorati on

shoul d no t b e ne ce ss ary more often than every 3 or

4weeks.

To c ha nge p ump lub ric ant:

1. Follow Pre ssure Relief Procedure, page 43.

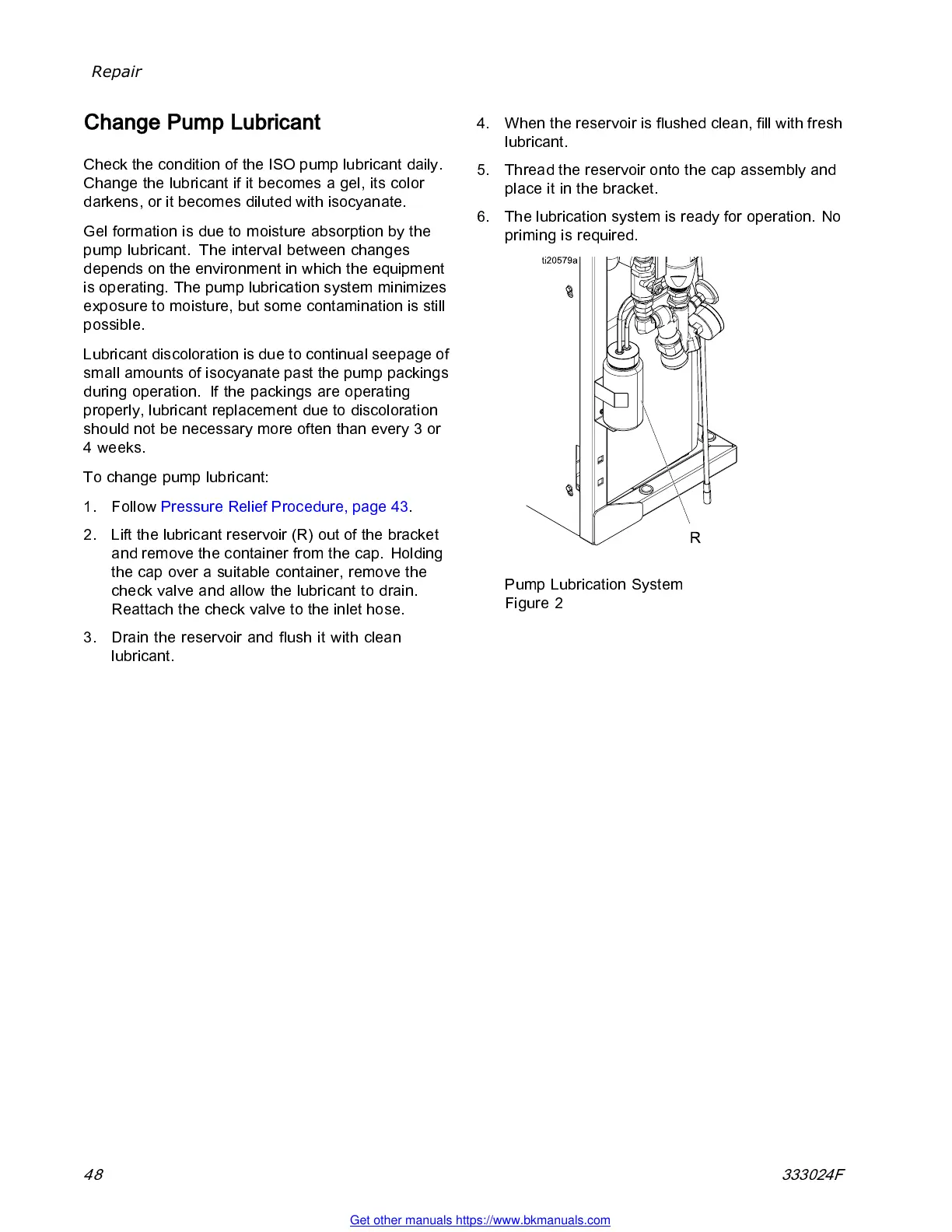

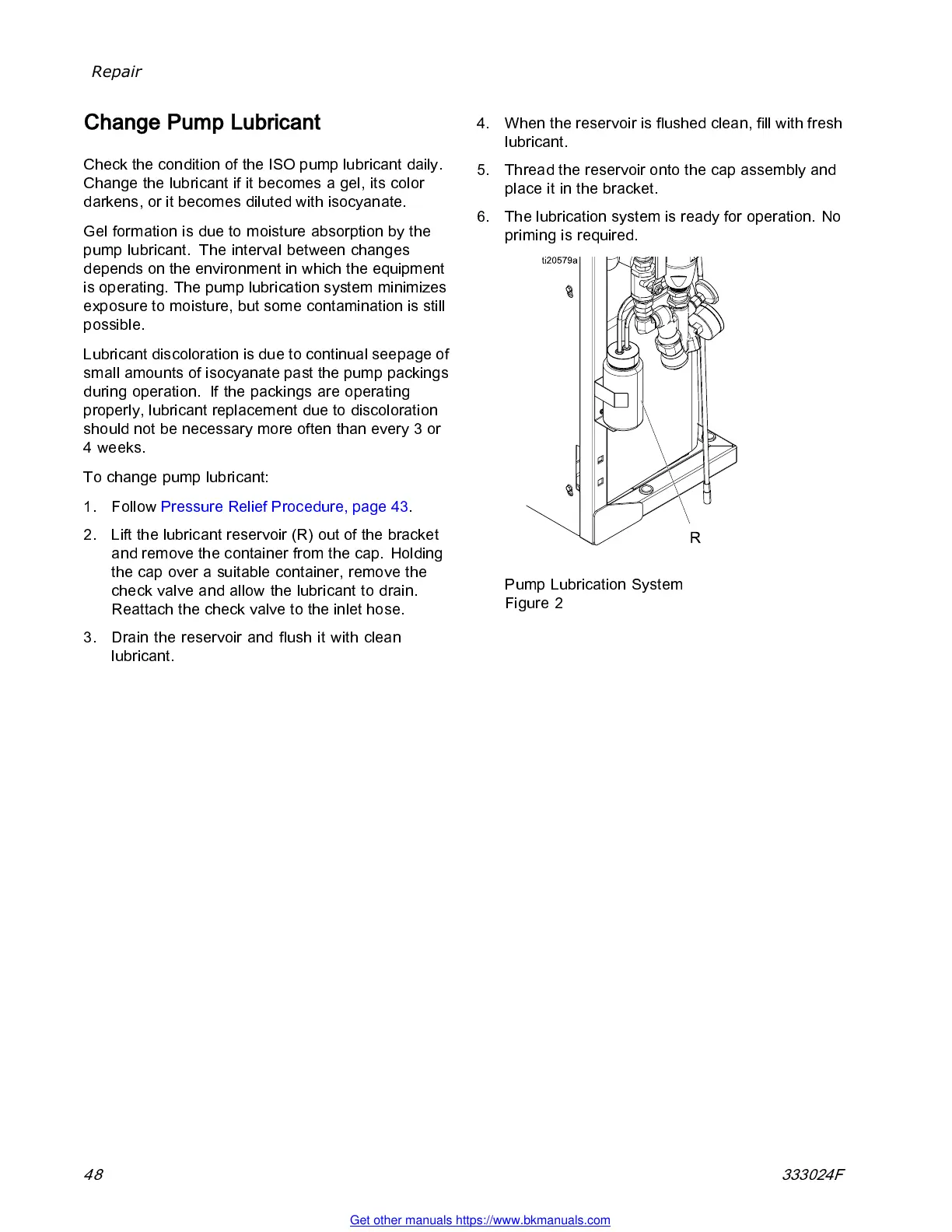

2. Lift th e lubric ant res erv oir (R) out o f the brack et

and remove the container from the cap. Holding

the cap over a suitable container, remove the

check v alve and allow the lubricant to drain.

Reattach the che ck valve to the inlet hose.

3. Drain the reservoir and flush it with clean

lubricant.

4. When the reservoir is flushed clean, fill with fresh

lubricant.

5. Thread the reservoir onto the cap assembly and

placeitinthebracket.

6. The lubrication system is ready for operation. No

priming is required.

Pump Lubrication System

Figure 2

48 333024F

Get other manuals https://www.bkmanuals.com

Loading...

Loading...