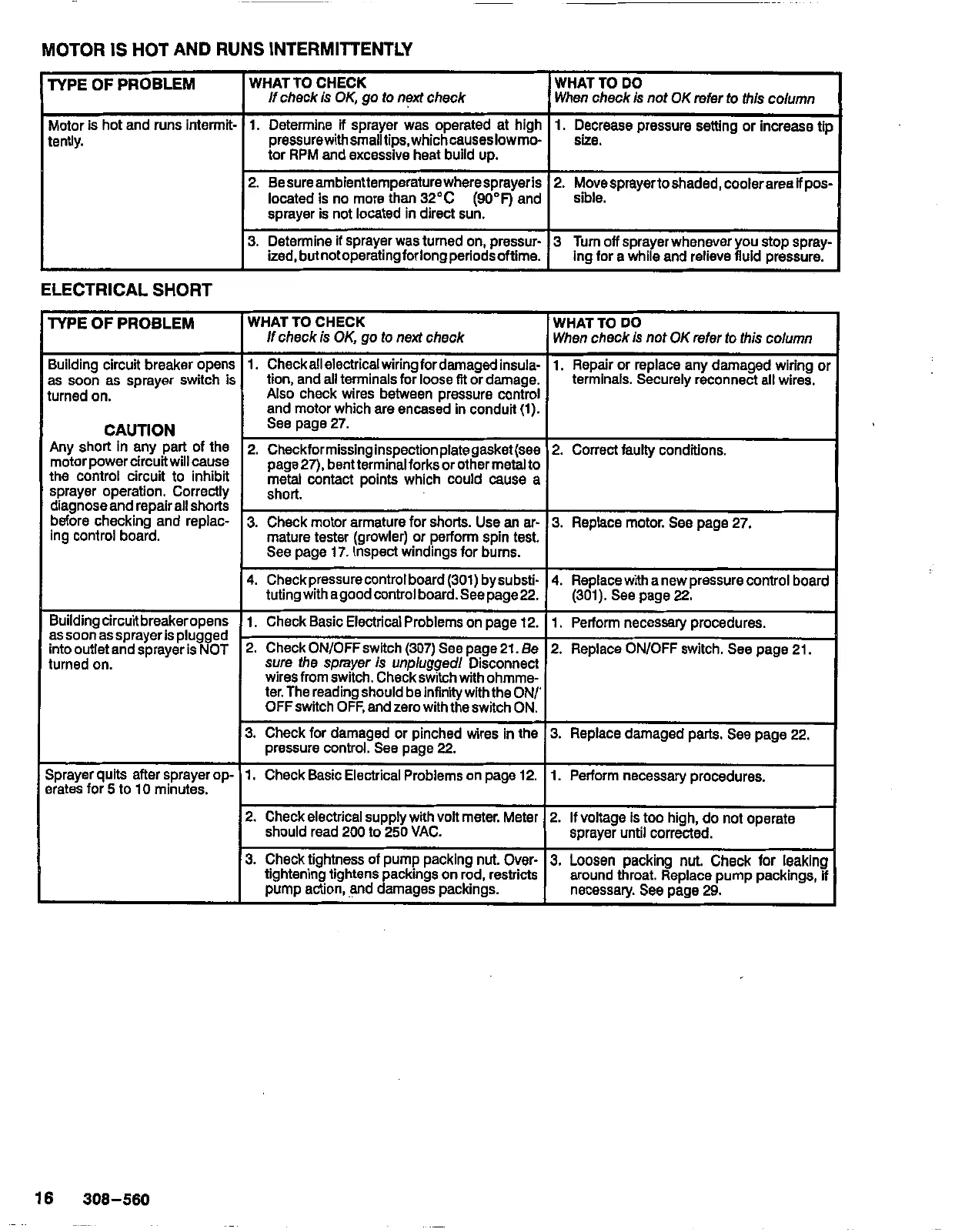

MOTOR

IS

HOT AND RUNS INTERMITTENTLY

TYPE

OF

PROBLEM

WHAT TO CHECK

If check is

OK,

go

to

next

check

WHAT TO DO

ing

for a while and relieve fluid pressure.

ized,

butnotoperatingforlongperiodsoftime.

3 Turn

off

sprayer whenever you stop spray-

3. Determine

if

sprayer was turned on, pressur-

sprayer is not located

in

direct sun.

sible.

located is no more

than

32%

(90OF)

and

sbe.

pressurewithsmalltips,whichcauseslowmo-

tor RPM and excessive heat build

up.

tently.

1.

Decrease pressure setting or increase

tip

1.

Determine

if

sprayer was operated at high

Motor is hot and runs intermit-

When check is

not

OK

refer

to

this column

2.

Besureambienttemperaturewheresprayeris

2.

Movesprayertoshaded,coolerareaifpos-

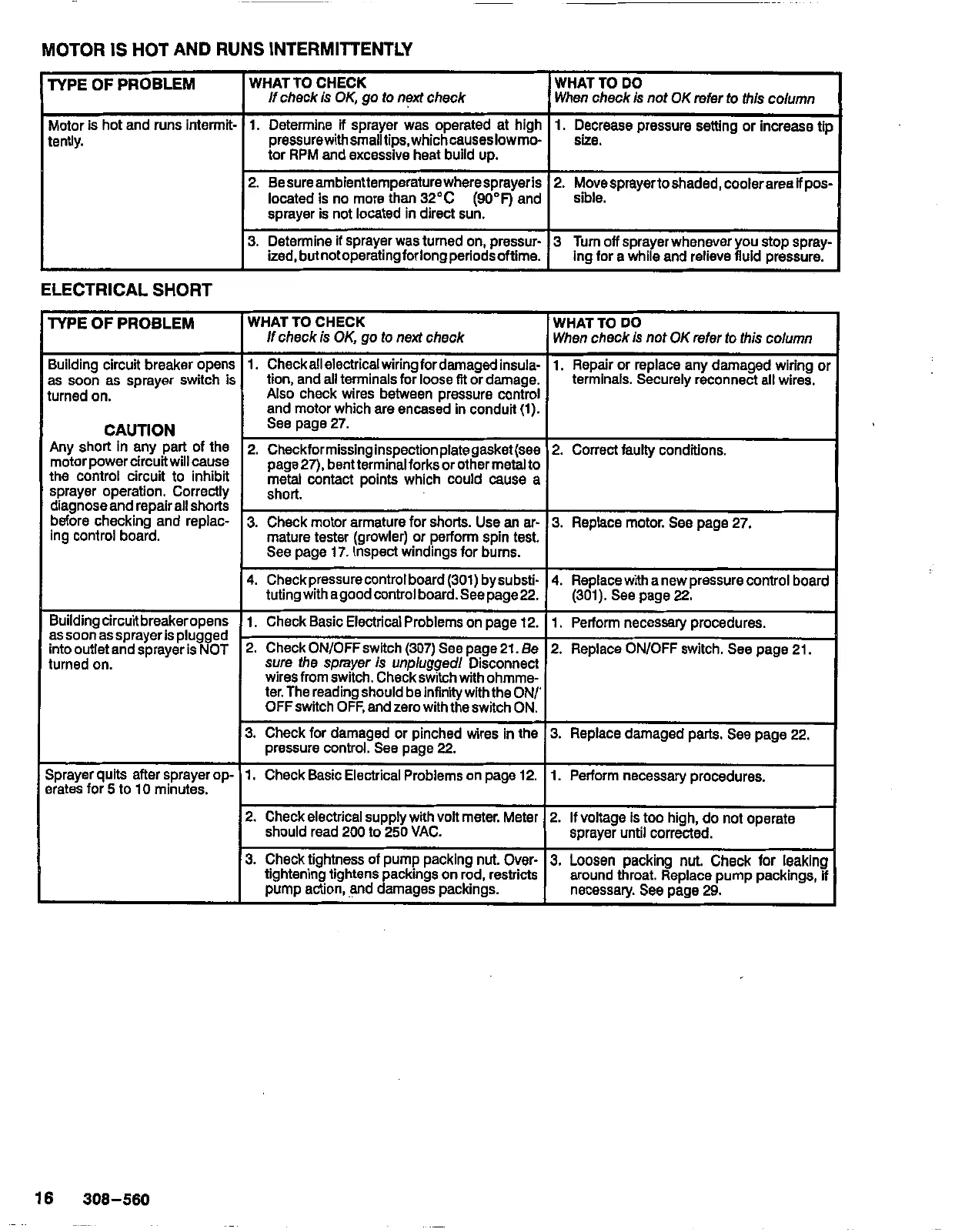

ELECTRICAL SHORT

TYPE

OF

PROBLEM

Building circuit breaker opens

as

soon as sprayer switch

is

turned on.

CAUTION

Any short

in

any part of the

motorpowercircuitwillcause

the control circuit to inhibit

sprayer operation. Correctly

diagnoseand repairallshorts

before checking and replac-

ing control board.

assoonassprayerisplugged

Buildingcircuitbreakeropens

into outlet and sprayer is NOT

turned on.

sprayer quits after sprayer

op-

)rates for

5

to

10

minutes.

WHAT

TO

CHECK

WHAT TO

DO

If check is

OK,

go

to

next

check

When check is

not

OK

refer

to

this column

I

1.

Checkallelectricalwiringfordamagedinsula-

Also check wires between Dressure control

terminals. Securely reconnect all wires.

tion, and

all

terminals for

loose

fit

or damage.

1.

Repair or replace any damaged wiring or

and motor which are encased in conduit

(1).

See

page

27.

2.

Checkformissinginspectionplategasket(see

2.

Correct faulty conditions.

..

page27),bentterminalforksorothermetalto

metal

contact points which could cause a

short.

3.

Check motor armature for shorts.

Use

an

ar-

3. Replace motor.

See

page 27.

mature tester (growler) or perform spin test.

See

page

17.

Inspect windings for burns.

4.

Checkpressurecontrol board (301) by substi-

2. Replace ON/OFF switch. See page

21.

?.

CheckON/OFFswitch (307)

See

page 21.

Be

1.

Perform necessary procedures.

1.

Check Basic Electrical Problems on page 12.

4.

Replace with anewpressure control board

tutingwithagoodcontrolboard.Seepage22.

(301).

See

page

22.

sure

the sprayer

is

unpluggedi Disconnect

wiresfromswitch.Checkswitchwithohmme-

ter.The reading should be infinity withtheONr

OFFswitchOFF,andzerowiththeswitchON.

I

3.

Check for damaged or pinched wires

in

the

1.

Perform necessary procedures.

I.

Check Basic Electrical Problems on page

12.

3. Replace damaged parts.

See

page

22.

pressure control.

See

page

22.

?.

Check electrical supply with volt meter. Meter

2.

If voltage is too high, do not operate

should read

200

to

250

VAC.

SDraver until corrected.

3.

Check tightness

Of

pump packing

nut.

Over-

3.

Loosen packing

nut.

Check

for leaking

tightening tightens packings on rod, restricts

around throat. Replace pump packlngs,

if

pump action,

and

damages packinas. necessaw.

See

Daoe

29.

1

Loading...

Loading...