Spin

Test

ELECTRIC

SHOCK

HAZARD

springs or brush holders while the

Do not touch the brushes, leads,

sprayer is plugged in to reduce the risk

of

electric shock and serious bodily injury.

INJECTION HAZARD

To reduce the risk of serious injury,

follow the illustrated

Pressure Rellef

Procedure

warning on page 12 when-

ever you are instructed to relieve pressure.

tor does not spin freely, the armature is shorted and the

revolutions before coming to a complete stop.

If

the

mo-

motor must be replaced. See page 27.

trical continuity.

For checking armature, motor winding and brush elec-

Setup

25.

Relieve pressure. Remove the drive housing. See page

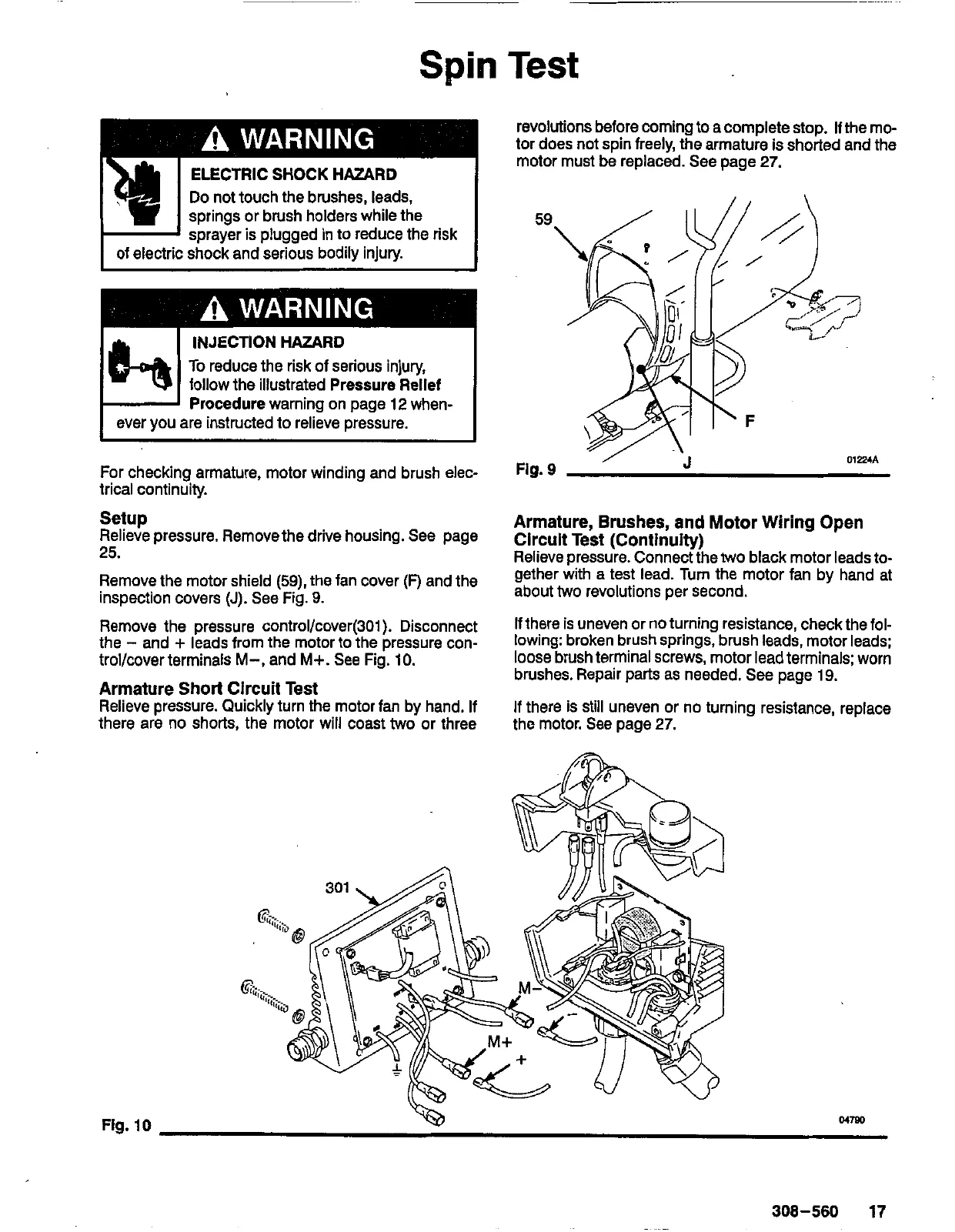

Remove the motor shield (59), the fan cover

(F)

and the

inspection covers

(J).

See Fig.

9.

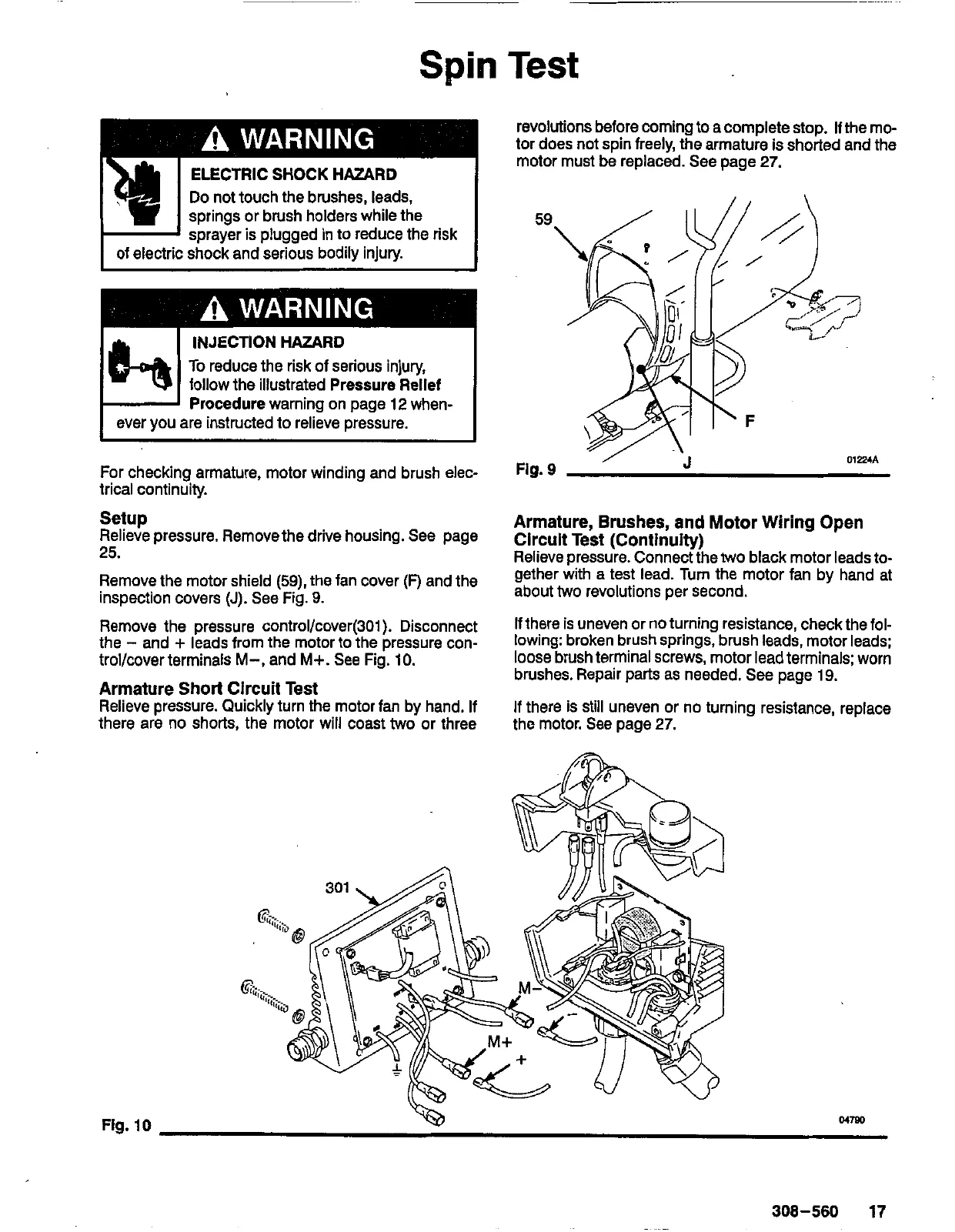

Remove the pressure control/cover(301). Disconnect

the

-

and

+

leads from the motor to the pressure con-

trol/cover terminals

M-,

and

M+.

See Fig. 10.

Armature Short Circuit Test

Relieve pressure. Quickly turn the motor fan by hand.

If

there are no shorts, the motor will coast two or three

/

Fig. 9

J

DlZ4A

Armature, Brushes, and Motor Wiring Open

Circuit Test (Continuity)

Relieve pressure. Connect thetwo black motor leads to-

about two revolutions per second.

gether with a test lead. Tum the motor fan by hand at

lowing: broken brush springs, brush leads, motor leads;

If

there

is

uneven or no turning resistance, check the

fol-

loose brush terminal screws, motor lead terminals; worn

brushes. Repair parts as needed. See page 19.

the motor. See page 27.

If

there

is

still uneven or no turning resistance, replace

Flg.

10

308-560

17

Loading...

Loading...