Displacement Pump Repair

REMOVING AND INSTALLING

PUMP

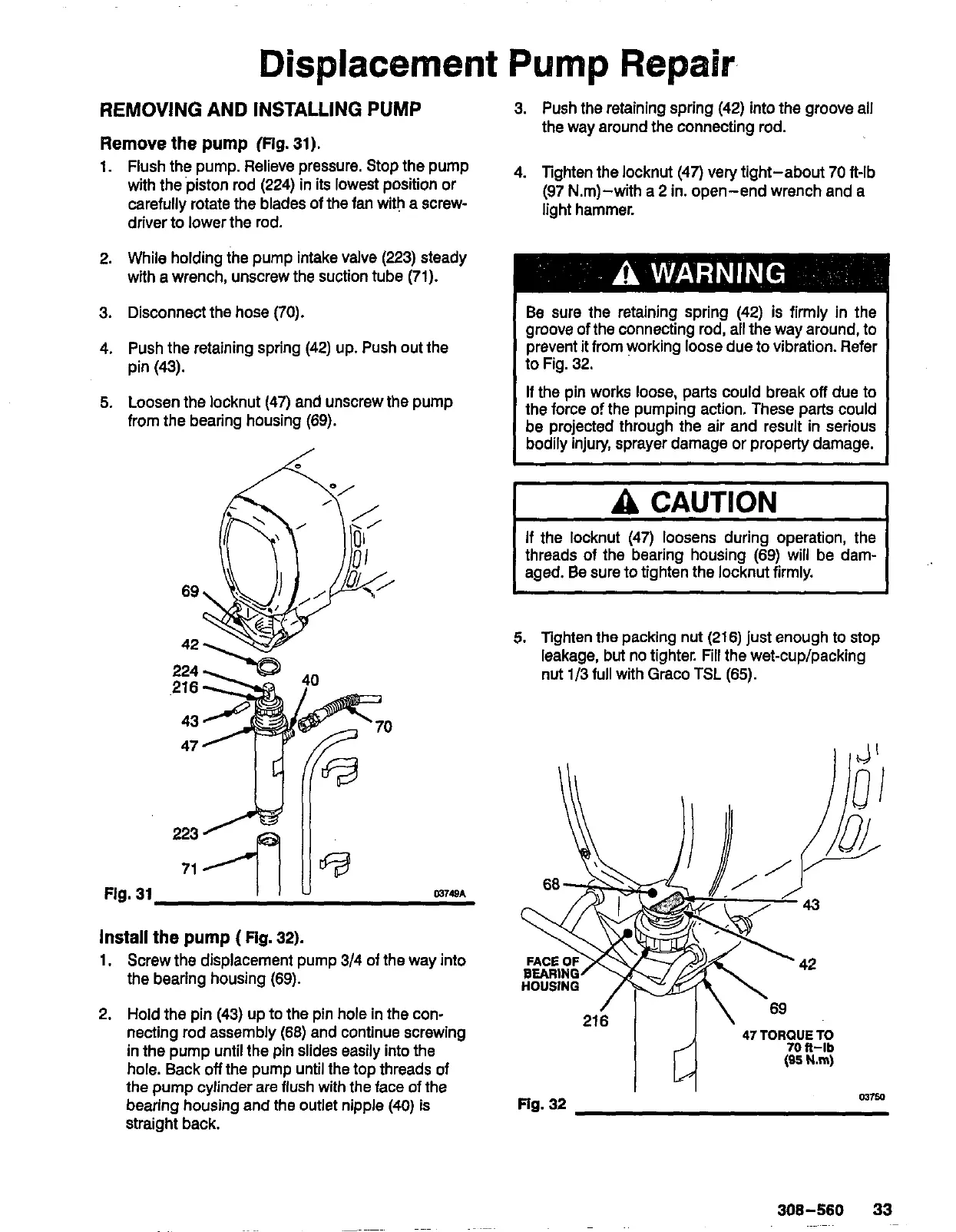

Remove the pump

(Flg.

31).

1.

Flush the pump. Relieve pressure. Stop the pump

with the piston rod

(224)

in its lowest position or

carefully rotate the blades of the fan wi@ a screw-

driver

to

lower the rod.

2.

While holding the pump intake valve

(223)

steady

with a wrench, unscrew the suction tube

(71).

3.

Disconnect the hose

(70).

4.

Push the retaining spring

(42)

up. Push out the

pin

(43).

5.

Loosen the locknut

(47)

and unscrew the pump

from the bearing housing

(69).

69

42

216

224

43

47

Flg.

31

IIU

mrw

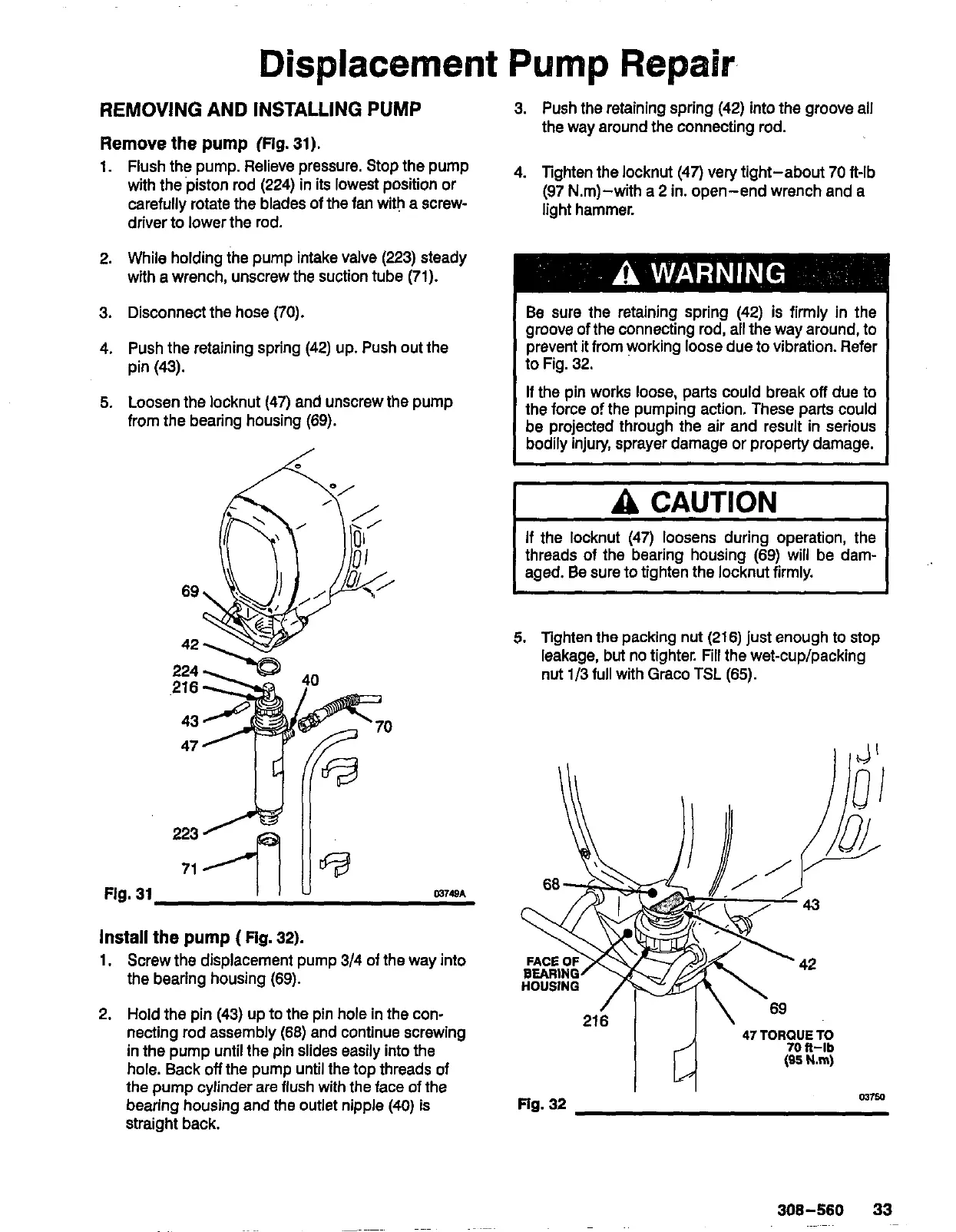

Install

the pump

(Fig.

32).

1.

Screw the displacement pump

3/4

of the way into

the bearing housing

(69).

2.

Hold the pin

(43)

up

to

the pin hole in the con-

necting rod assembly

(68)

and continue screwing

in the pump until the pin slides easily into the

the pump cylinder are flush with the face of the

hole. Back

off

the pump until the top threads of

straight back.

bearing housing and the outlet nipple

(40)

is

3.

Push the retaining spring

(42)

into the groove all

the way around the connecting rod.

4.

Tighten the locknut

(47)

very tight-about

70

ft-lb

light hammer.

(97

N.m)-with a

2

in. open-end wrench and a

groove of the connecting rod, all the way around, to

Be sure the retaining spring

(42)

is

firmly in the

prevent it from working loose due to vibration. Refer

to Fig.

32.

If

the

pin works

loose,

parts could break

off

due to

the force

of

the pumping action. These parts could

be

projected through the air and result in serious

bodily injury, sprayer damage or property damage.

I

A

CAUTION

I

If

the locknut

(47)

loosens during operation, the

threads of the bearing housing

(69)

will be dam-

aged.

Be

sure

to

tighten the locknut firmly.

5.

Tighten the packing nut

(216)

just enough to stop

leakage, but no tighter. Fill the wet-cup/packing

nut

1/3

full

with Graco

TSL

(65).

I

Fig.

32

I

308-560

33

Loading...

Loading...