11

Grant Vortex External Module

4 - GENERAL BOILER INFORMATION

4 A metal bowl type filter with a replaceable

micronic filter must be fitted in the fuel supply line

adjacent to the boiler. A shut-off valve should be

fitted before the filter, to allow the filter to be

serviced.

5 A flexible fuel hose, adaptor and

1

/

4

" BSP isolation

valve are supplied loose with the boiler for the final

connection to the burner. If a two pipe system or

'Tiger Loop' type de-aerator is used, an additional

flexible fuel hose (600 mm) and

3

/

8

" to

1

/

4

" BSP male

adaptor are available to purchase from your local

stockist. If a 'Tiger Loop' is fitted it should not be

fitted indoors or within a boiler casing.

6 Metal braided flexible hoses should be replaced

annually when the boiler is serviced. Long life

flexible hoses should be inspected annually and

replaced at least every 60 months.

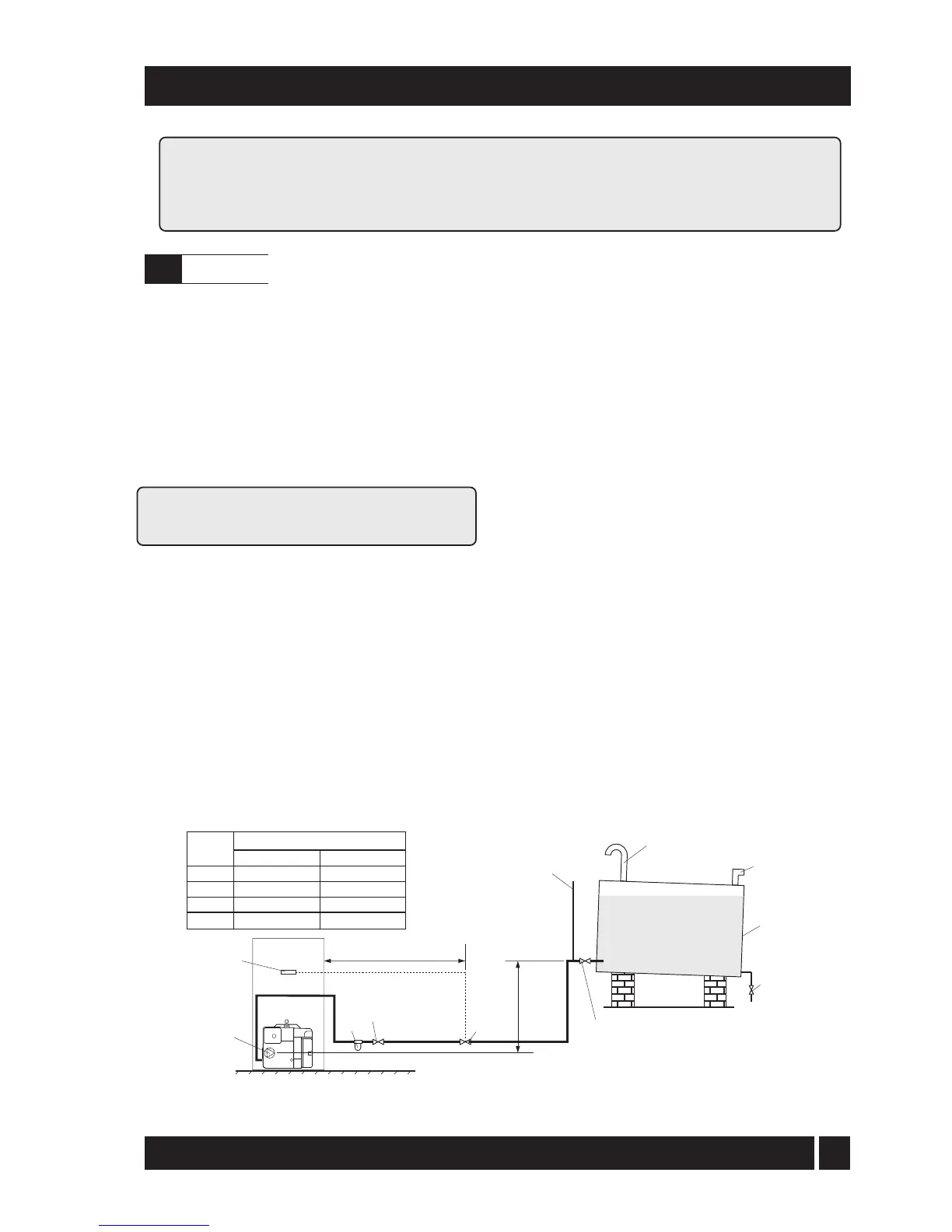

4.4.3 Single pipe system - (See Fig. 2)

1 Where the storage tank outlet is above the burner

the single pipe system should be used. The height

of the tank above the burner limits the length of

pipe run from the tank to the burner.

2 As supplied the burner is suitable for a single pipe

system.

4.4.1 Fuel storage

The tank should be positioned in accordance with the

recommendations given in BS 5410:1:1997, which gives

details of filling, maintenance and protection from fire.

A steel tank may be used and must be constructed to

BS 799:5:1987 and OFST 200.

A galvanised tank must not be used.

A plastic tank may be used and must comply with

OFST 100.

Note: Plastic tanks should be adequately and

uniformly supported on a smooth level surface, across

their entire base area.

4.4.2 Fuel pipes

1 Fuel supply pipes should be of copper tubing with

an external diameter of at least 10 mm.

Galvanised pipe must not be used.

All pipe connections should preferably use flared

fittings. Soldered connections must not be used on

oil pipes.

2 Flexible hoses must not be used outside the boiler case.

3 A remote sensing fire valve (not a fusible head type)

must be installed in the fuel supply line, with the

sensing head located above the burner.

Recommendations are given in BS 5410:1:1997.

Fuel supply

4.4

Regional statutory requirements may deem this appliance to be a 'controlled service'.

Where this is the case, it is a legal requirement that the appliance is installed and

commissioned either under the remit of building control or by a 'Competent person' such

as a suitably qualified Oftec registered technician.

Fig. 2 - Single pipe system

Filter

Fire

valve

Shut-off

valve

Shut-off

valve

A

Sludge

valve

Fill

pipe

Vent

pipe

Level

gauge

Fuel

storage

tank

Head A

(m)

Maximum pipe run (m)

0.5

1.0

1.5

2.0

10 mm OD pipe

10

20

40

60

12 mm 0D pipe

20

40

80

100

Fire

valve

sensor

Pump

1m

Loading...

Loading...