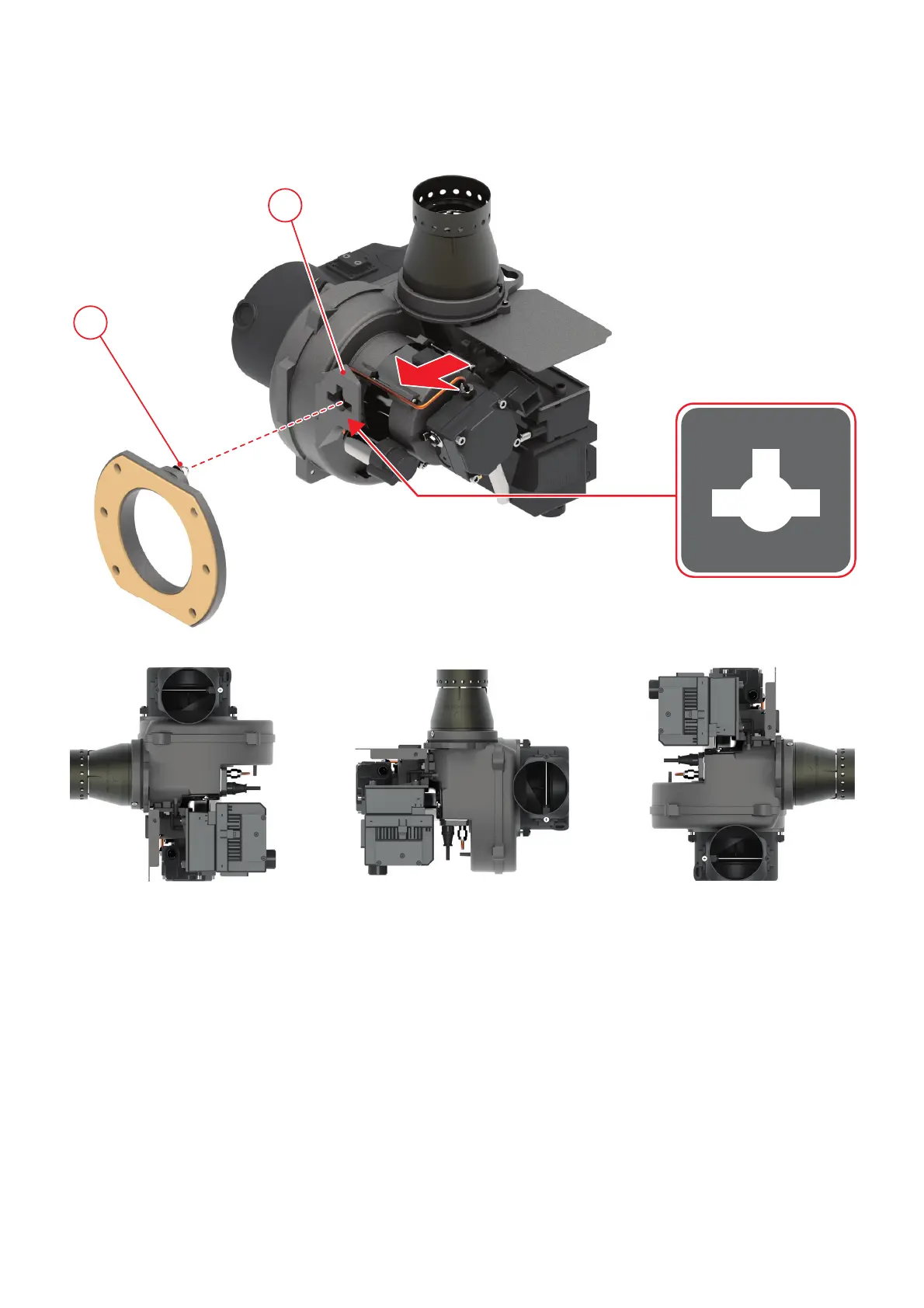

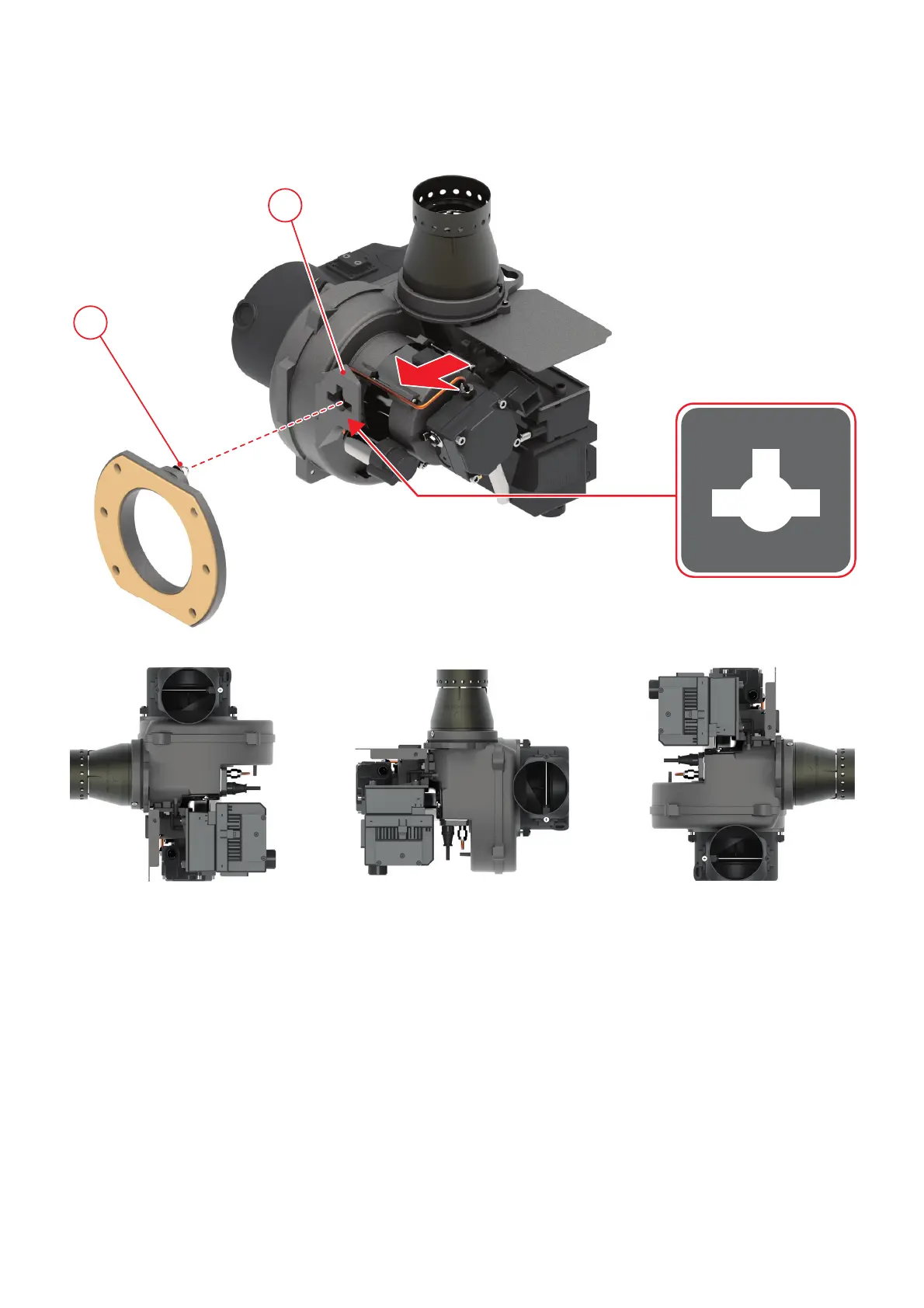

BAC

11

12

B

AC

Position A:

- inspection and cleaning of the internal rotor.

Position B:

- combustion head inspection

- inspection and maintenance of the nozzle

- inspection and maintenance of the electrode group

Position C:

- pump inspection and maintenance

- coil inspection and maintenance

- inspection and maintenance of the capacitor.

10.6 BURNER MAINTENANCE

- Check the oil supply components (hose, pump, fuel supply hose)

and their connections to detect leaks and signs of wear, and

replace the parts if necessary.

To facilitate maintenance operations, fi x the burner to the boiler by

inserting the fi xing screw (11) in the hole (12) located on the base of

the burner. Use one of the three square grooves located on the base

of the burner to fi x the burner, which must be turned to the position

most suitable for carrying out the maintenance operation.

- Check that the electrical connection and connection cables are not

damaged, and replace them if necessary.

- Check the pump fi lter and clean it if necessary.

- Clean the fan and its housing and check that they are not

damaged.

- Check and clean the combustion head.

- Check the ignition electrodes, adjust or replace them if necessary.

- Replace the nozzle.

- Fit the combustion head. Respect the adjustment dimensions.

- Install the burner.

- Start the burner, check the exhaust gas data and adjust the burner

settings if necessary.

Maintenance Of Your Boiler Page 33

Loading...

Loading...