16

Be careful during fuel lter installation to prevent contamination

from getting into the suction line.

OIL FILTER

• Unscrew oil ller plug (18).

• Use wire hook to remove the oil lter (h) through the oil ller hole

(g. Y).

• Wash the oil lter in petrol or replace with a new one.

• Remove dirt from the tank.

• Install the oil lter in the tank.

• Tighten oil ller plug (18).

When putting the oil lter into the tank make sure it reaches front

right corner.

IGNITION PLUG

To maintain reliable operation of the device, check condition of the

ignition plug on a regular basis.

• Remove air lter lid (4).

• Remove air lter (d).

• Remove wire (i) from the ignition plug.

• Put on plug key (included) and unscrew the ignition plug (g. Z).

• Clean and adjust spacing between contacts (0.65 mm) (replace

ignition plug when necessary).

OTHER INSTRUCTIONS

Ensure there are no fuel leaks, loosened joints or damages of main parts,

especially main handle joints and guide bar xing. When you nd any

damage, make sure it is repaired before next use of the chain saw.

All faults should be repaired by service workshop authorized by the

manufacturer.

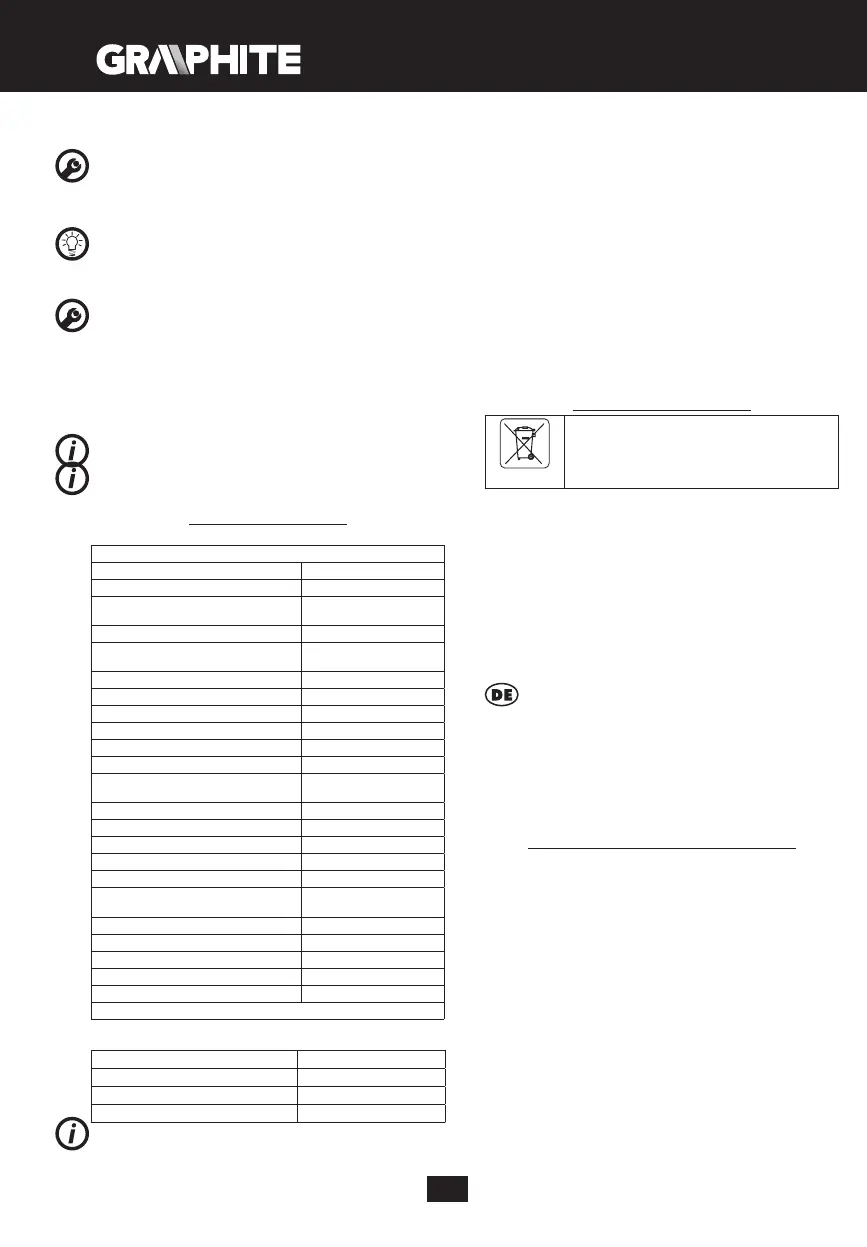

TECHNICAL PARAMETERS

RATED PARAMETERS

Petrol Chain Saw

Rated parameter Value

Engine displacement 52 cm

3

Guide bar working length 58G953 - 16 ‚’ (400 mm)

58G954 - 18 ‚’ (450 mm)

Engine power 2 kW (2,7 KM)

Engine speed with cutting system

(maximum)

10500 min

-1

Idle rotational speed 3000 min

-1

Fuel Petrol / oil (for 2-stroke engines) 25:1

Fuel tank capacity 550 ml

Chain oil tank capacity 260 ml

Ignition system Spark

Ignition plug L7T, BPM7A, CJ6Y

Oil feed system Automated pump with

controller

Chain wheel (teeth x pitch) 7T x 8,255 mm

Chain pitch 0,325” (8,255mm)

Chain thickness 0,058” (1,47 mm)

Dimensions (LxWxH) (w/o guide bar) 270x235x225mm

Weight (w/o guide bar and chain) 5,53 kg

Chain guiding in guide bar Bearing mounted toothed

wheel

Cutting system speed 4000 min-1

Fuel consumption 1,63 l/h

Throttle-type carburetor MP16

Chain type .325 0.058

Year of production 2021

58G953/58G954 denes type and indication of the device

NOISE LEVEL AND VIBRATION PARAMETERS

Sound pressure L

PA

= 96,7 dB (A) K=3dB (A)

Sound power L

WA

= 110 dB(A) K=3dB(A)

Vibration acceleration (front handle) a

h

= 7,907 m/s

2

K=1,5 m/s

2

Vibration acceleration (rear handle) a

h

= 6,879 m/s

2

K=1,5 m/s

2

Noise and vibration information

Noise produced by the device is dened with: level of produced sound

pressure L

pA

and level of sound power L

wA

(where K is measurement

uncertainty). Vibrations produced by the device are dened with

vibration acceleration value a

h

(where K is measurement uncertainty).

Sound pressure L

pA

, sound power L

wA

and vibration acceleration a

h

specied in this manual have been measured in accordance with the

standard EN ISO 11681-1A:2011. Specied vibration level a

h

can be used

to compare tools and for initial evaluation of exposition to vibrations.

Specied vibration level is typical only for the main applications of the

device. When the device is used for other purposes or with dierent

working tools, the vibration level may change. Insucient or too rare

maintenance may increase vibration level. The abovementioned factors

may lead to higher exposure to vibrations during whole working time.

To precisely dene exposure to vibrations, include periods when

the device is switched o and when it is switched on but not used

for working. Once all factors have been carefully considered, total

exposition to vibrations may be signicantly lower.

To protect the user from results of exposure to vibrations, use additional

safety measures such as: device and working tool periodic maintenance,

proper hand temperature conditions, good work organisation.

ENVIRONMENT PROTECTION

Do not dispose of combustion engine driven products with

household wastes, they should be utilized in proper plants.

Obtain information on waste utilization from your seller or local

authorities. Worn out equipment contains substances active

in natural environment. Unrecycled equipment constitutes a

potential risk for environment and human health.

* Right to introduce changes is reserved.

“Grupa Topex Spółka z ograniczoną odpowiedzialnością” Spółka komandytowa with

seat in Warsaw at ul. Pograniczna 2/4 (hereinafter Grupa Topex) informs, that all

copyrights to this instruction (hereinafter Instruction), including, but not limited to,

text, photographies, schemes, drawings and layout of the instruction, belong to Grupa

Topex exclusively and are protected by laws accordingly to Copyright and Related

Rights Act of 4 February 2004 (ustawa o prawie autorskim i prawach pokrewnych, Dz.

U. 2006 No 90 item 631 with later ammendments). Copying, processing, publishing,

modications for commercial purposes of the entire Instruction or its parts without

written permission of Grupa Topex are strictly forbidden and may cause civil and legal

liability.

ÜBERSETZUNG DER

ORIGINALBETRIEBSANLEITUNG

MOTORKETTENSÄGE

58G953/58G954

ACHTUNG: LESEN SIE VOR DER INBETRIEBNAHME DER

MOTORKETTENSÄGE GRÜNDLICH DIE VORLIEGENDE

BETRIEBSANLEITUNG DURCH UND BEWAHREN SIE SIE AUF.

DETAILLIERTE SICHERHEITSVORSCHRIFTEN

DER SICHERE GEBRAUCH VON MOTORKETTENSÄGEN

Warnung!

• Personen, die sich mit der Betriebsanweisung nicht vertraut

gemacht haben, dürfen mit der Motorkettensäge nicht arbeiten.

• Die Motorkettensäge darf ausschließlich zum Schneider von Holz

verwendet werden.

• Der Benutzer haftet voll für das Risiko des anderweitigen

Gebrauchs der Motorkettensäge mit dem Bewusstsein, dass dies

gefährlich sein kann.

•

Der Hersteller haftet für keine Schäden, die aus dem nicht

ordnungsmäßigen Gebrauch der Motorkettensäge resultieren.

ARBEITSPLATZ

a. Achten Sie auf einen aufgeräumten Arbeitsplatz und sorgen

für eine ausreichende Beleuchtung des Arbeitsplatzes. Der

unaufgeräumte Arbeitsplatz und die schlechte Beleuchtung tragen zu

Arbeitsunfällen beim Gebrauch von Motorkettensägen bei.

b. Halten Sie Kinder und Beobachter vom Einsatzort fern. Die

Ablenkung der Aufmerksamkeit beim Bediener kann zum Verlust der

Kontrolle über das Gerät führen.

PERSONENSICHERHEIT

a. Die persönliche Schutzausrüstung wie Uniform, Schutzbrille,

Loading...

Loading...