48

D Series Modular Air-cooled Scroll Chillers

Service Manual

6. Reinstall

the electronic

H[SDQVLRQ

valve coil and

vacuum the

system and

then charge

refrigerant

and lastly

put the

panel back

ƹ

The coil shall be matched with the valve

ERG\H[DFWO\

ƹ

T

he degree of vacuum shall be kept as low

as -1.0 bar.

ƹ

The refrigerant charge and quality shall comply

ZLWKWKHVSHFL¿FDWLRQRQWKHQDPHSODWH

ƹ

$IWHUUHSODFHWKHHOHFWURQLFH[SDQVLRQ

valve, energize the unit again.

ƹ

Reinstall the panel.

4 ROUTINE MAINTENANCE

5RXWLQHPDLQWHQDQFHVKDOOEHSHUIRUPHGE\WKHVNLOOHGDQGTXDOL¿HGVHUYLFHPHQ

(1). Refrigerant Leakage

Suds is usually used for the leakage test by applying it at the spot (soldering spots, valve pistols,

connectors) where leakage is probably to occur. During the test, if soap bubbles pop up, it indicates leakage

H[LVWVDQGUHSDLULVUHTXLUHG,IVXGVIDLOVWRZRUNDHOHFWURQLFOHDNDJHGHWHFWRUVLVDDOWHUQDWLYH5HIULJHUDQW

charge can be checked by measuring the suction and discharge pressure. Leakage test should be performed

wherever leakage occurs or some components of the refrigeration system are replaced.

There are two difference conditions for charging refrigeration stated as below.

ƹ

Complete charging

In this case, take a leakage test by charging hi-pressure nitrogen (15~20kg) or refrigerant into the system. If

VROGHULQJLVUHTXLUHGQRWHWKDWJDVLQVLGHWKHV\VWHPPXVWEHH[SHOOHG¿UVWO\7KHZKROHV\VWHPPXVWEHGULHG

and vacuumed prior to charging.

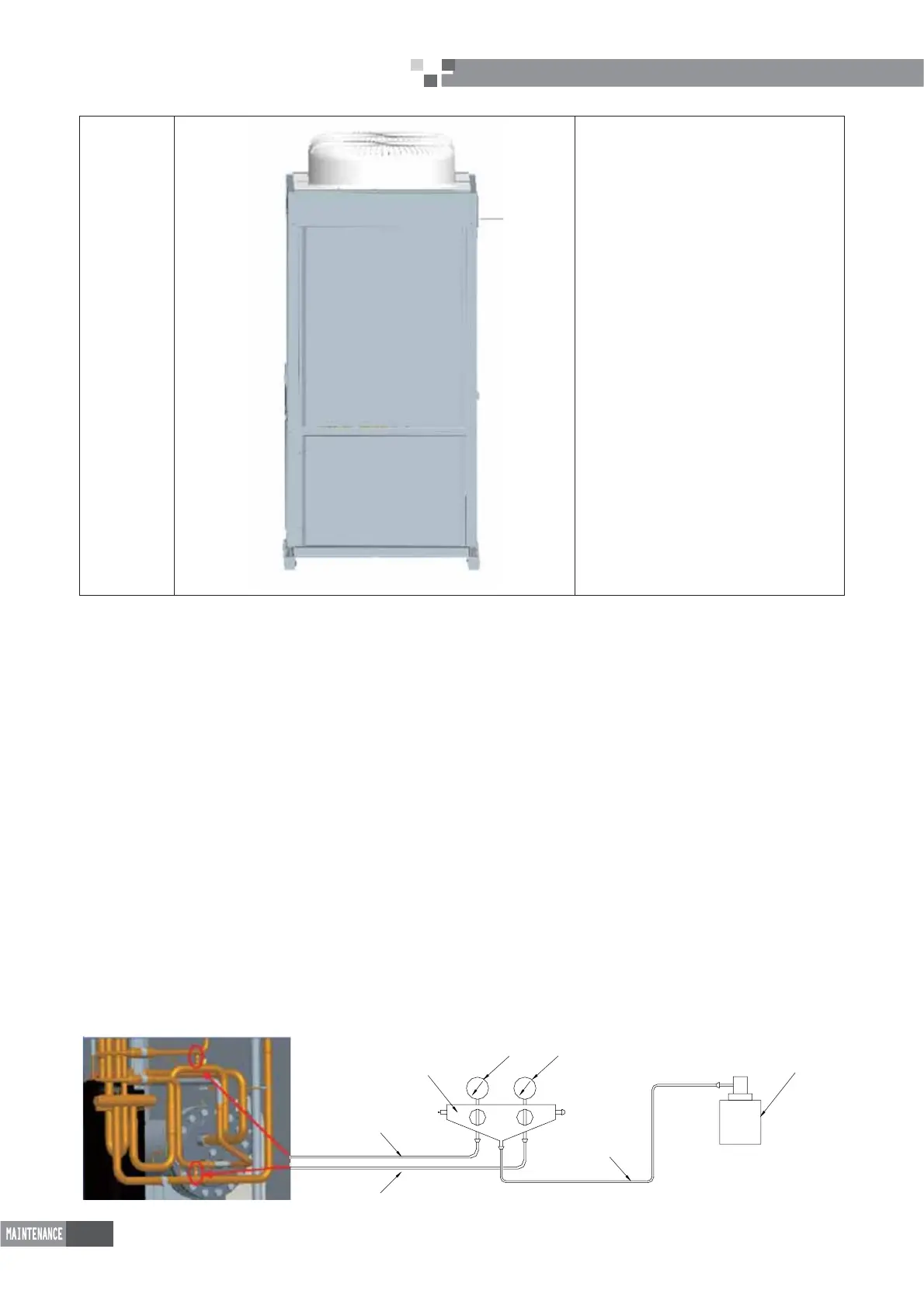

a. Connect the manifold gage.

b. Vacuum the system with a vacuum pump.

6WHS([SHOWKHKLSUHVVXUHQLWURJHQIRUOHDNDJHWHVW

Step 2: Connect the pipeline at both the high and low pressure sides of the manifold gage as shown in the

¿JXUHEHORZ1RWHWKDWYDFXXPLQJVKDOOEHWDNHQDWERWKVLGHV7KHGHJUHHRIYDFXXPZLOOUHIHUWRWKHUHDGLQJ

of the manometer at the low side.

Manifold gage

Hi-pressure gage

Low-pressure gage

Vacuum pump

Pipeline

Pipeline

Pipeline

ТОО "Everest climate" г. Алматы, Варламова 1а, тел.+7 727 230 00 10, e-mail: info@aircon.kz, сайт:www.aircon.kz

Loading...

Loading...