GREE DC Inverter Multi VRF System II Service Manual

62

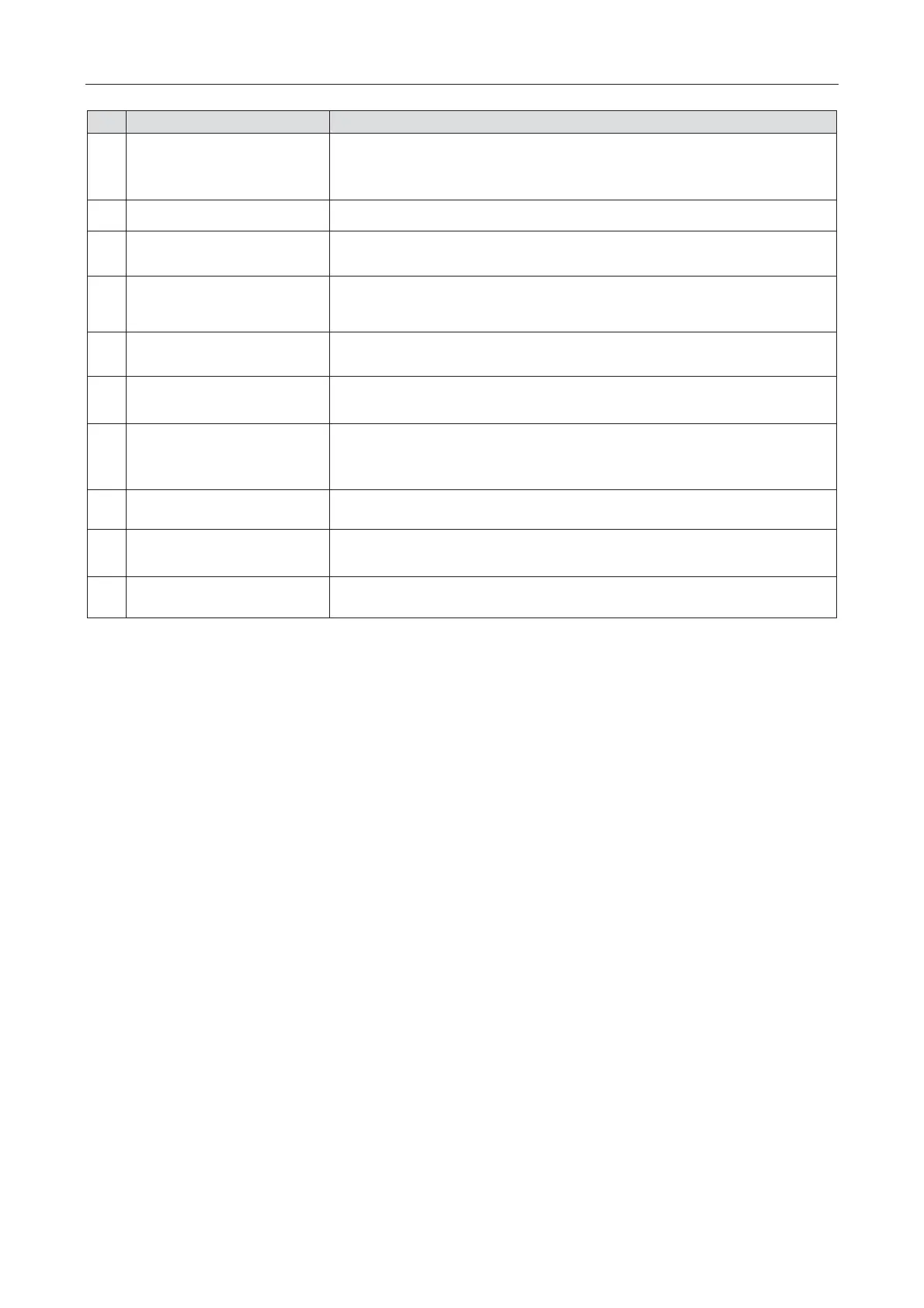

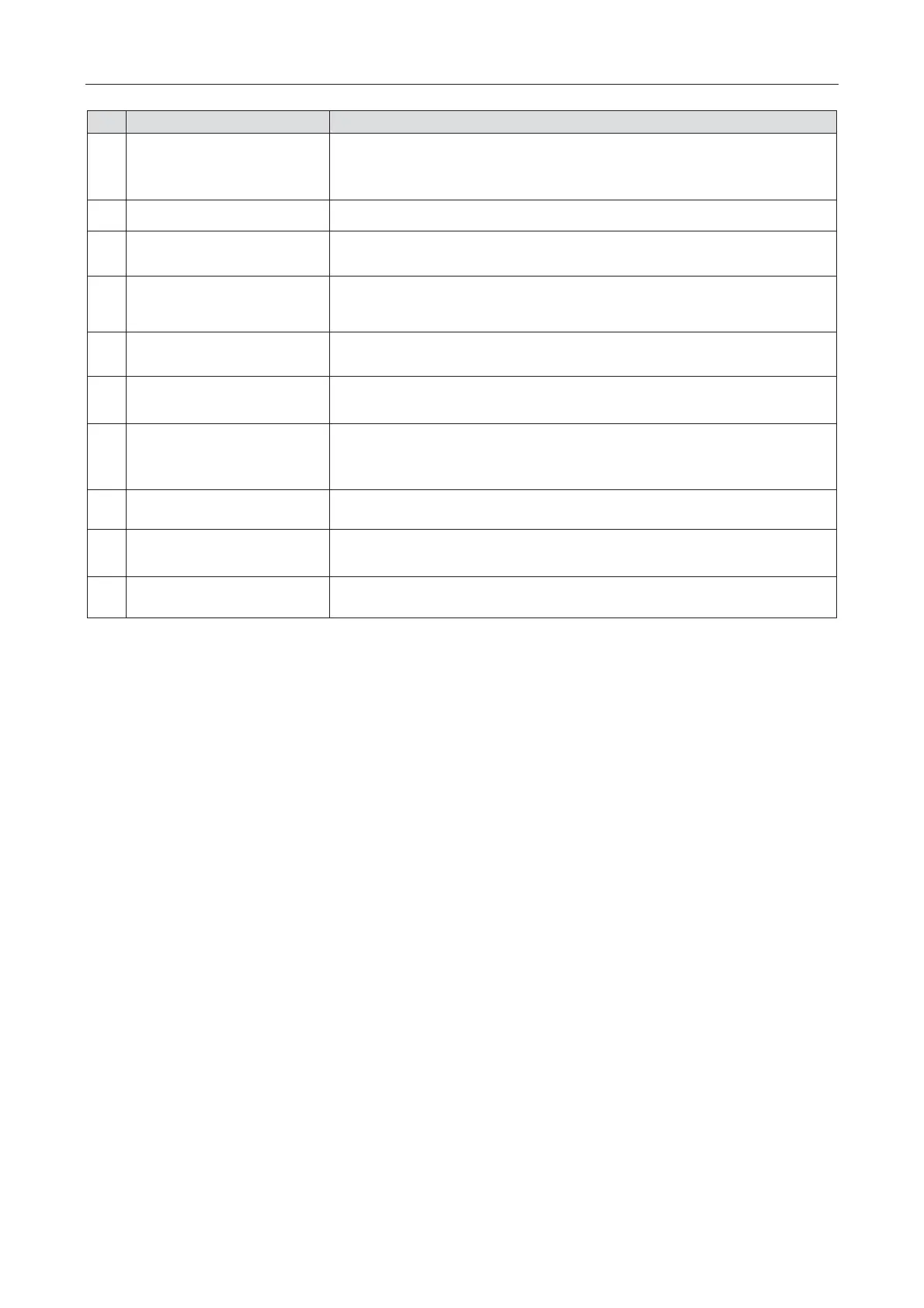

The ratio of slop for condensate

water pipe is insufficient or the

condensate water pipe is

incorrectly connected.

Reverse slop or inconsistent connection of condensate water pipe can hinder the

smooth drainage and cause leakage of the IDU.

The air channel is improperly

fixed.

The air channel will deform; vibration and noise occur during unit operating.

The guide vane of air channel is

not reasonably manufactured.

Uneven air quantity allocation reduces the overall performance of the air

conditioner.

The refrigerant pipe or

condensate water pipe does not

meet the insulation requirement.

Water can easily condensate and drip to damage the indoor decoration, or even

trigger the protection mode of system due to overheating operation.

The installation space for IDU is

insufficient.

Since there is a lack of space for maintenance and checking, indoor decoration

might need to be damaged during such operation.

The IDU or the location of the air

outlet or return air inlet is not

designed reasonably.

The air outlet or return air inlet may be short-

circuited, thus affecting the air

conditioning performance.

The ODU is improperly installed.

The ODU is difficult to be maintained; unit exhaust is not smooth, which reduces

the heat exchanging performance or even prevent the

system from normal

operation; in addition, the cold and hot air for heat exchange and the noise may

annoy people in surrounding areas.

Power cables are incorrectly

provided.

Unit components may be damaged and potential safety hazard may occur.

Control communication cables

are incorrectly provided or

improperly connected.

The normal communication in the system fails or the control over IDUs and ODUs

turn in a mess.

Control communication cables

are not properly protected.

The communication cables are short-

circuited or disconnected, and the unit

cannot be started up due to communication failure.

Understand the special requirement (if any) for unit installation before implementation to ensure

installation quality. Relevant installers must have corresponding engineering construction qualifications.

Special type operators involved in the engineering implementation, such as welders, electricians,

and refrigeration mechanics must have relevant operating licenses and are accredited with vocational

qualification certification.

2 Installation Materials Selection

The materials, equipment and instruments used during air conditioning engineering construction

must have certifications and test reports. Products with fireproof requirements must be provided with

fireproof inspection certificates and must meet national and relevant compulsory standards. If

environmentally-friendly materials are to be used as required by customers, all such materials must meet

national environmental protection requirement and be provided with relevant certificates.

2.1 Refrigerant piping

a. Material requirement: Dephosphorization drawing copper pipe for air conditioners;

b.Appearance requirement: The inner and outer surface of pipe should be smooth without pinhole,

crack, peeling, blister, inclusion, copper powder, carbon deposition, rust, dirt or severe oxide film,

and without obvious scratch, pit, spot and other defects.

c.Test report: Certifications and quality test reports must be provided.

d.The tensile strength must be at least 240 kgf/mm².

Loading...

Loading...