Unit

Size

6 - - - 3/8 -

7 - - - 3/8 -

9 - - - 1/2 1/2

10 3/8 1/4 5/32 1/2 1/2

12 3/8 - 5/32 - 1/2

13 7/16 1/4 5/32 - 1/2

15 1/2 1/4 5/32 - 1/2

16 1/2 1/4 5/32 - -

18 5/8 3/8 5/32 - 1/2

20 5/8 3/8 5/32 - 5/8

22 11/16 - 5/32 - 5/8

24 3/4 3/8 5/32 - -

25 - - - - 3/4

27 7/8 - 3/16 - 3/4

30 15/16 1/2 3/16 - 3/4

33 1-1/16 - 3/16 - -

36 1-3/16 1/2 3/16 - -

4

PRE-STARTING CHECKS

Wheels must rotate freely and not rub on the inlet

venturi. Model SWB wheels overlap the inlet venturi

as shown in Figure 2. Refer to the SWB fan wheel

overlap and radial gap chart for proper dimensions.

Models SFD and SFB wheels do not overlap the

venturi, but have a gap between the inlet venturi and

the wheel (Fig. 3). Wheel position is preset at the

factory and the unit is test run. Wheel movement

may occur during shipment or installation and wheel

alignment may be necessary.

On belt drive units, centering can be accomplished

by (1) loosening the inlet cone bolts to move the

inlet cone or by (2) loosening the bearings in order

to move the shaft. Wheel and inlet cone overlap can

be adjusted by loosening the wheel hub set screw

and moving the wheel to the desired position.

Tighten all fasteners and set screws securely and

realign drive pulleys after adjustment. Check pulleys

and belts for proper alignment to avoid unnecessary

belt wear, noise, vibration and power loss. Motor

and drive shafts must be parallel and pulleys in line

(Fig. 4)

The adjustable motor pulley is set at the factory for

the fan RPM specified by the customer. Fan RPM

can be increased by closing or decreased by

opening the adjustable motor pulley. Multi-groove

variable pitch pulleys must be adjusted an equal

number of turns open or closed. Any increase in fan

speed represents a substantial increase in load on

the motor.

To avoid motor overheating and possible burnout,

motor load amperes should always be checked and

compared to nameplate rating when fan speed is

increased.

Rotation direction of the wheel is critical and

incorrect rotation will result in reduced air

performance, increased motor loading and possible

motor burnout.

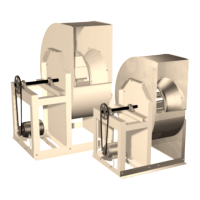

MODEL SWB

Fig. 2

Wrong Wrong Right

Fig. 4

APPROXIMATE WHEEL CLEARANCE DIMENSIONS

Overlap (inches)

Series

100

Series

200

Radial Gap

(inches)

SWB

SFD

GAP

(in.)

SFB

GAP

(in.)

MODEL SFD OR SFB

Fig. 3

Loading...

Loading...