-34-

Model G0708 (Mfd. Since 1/15)

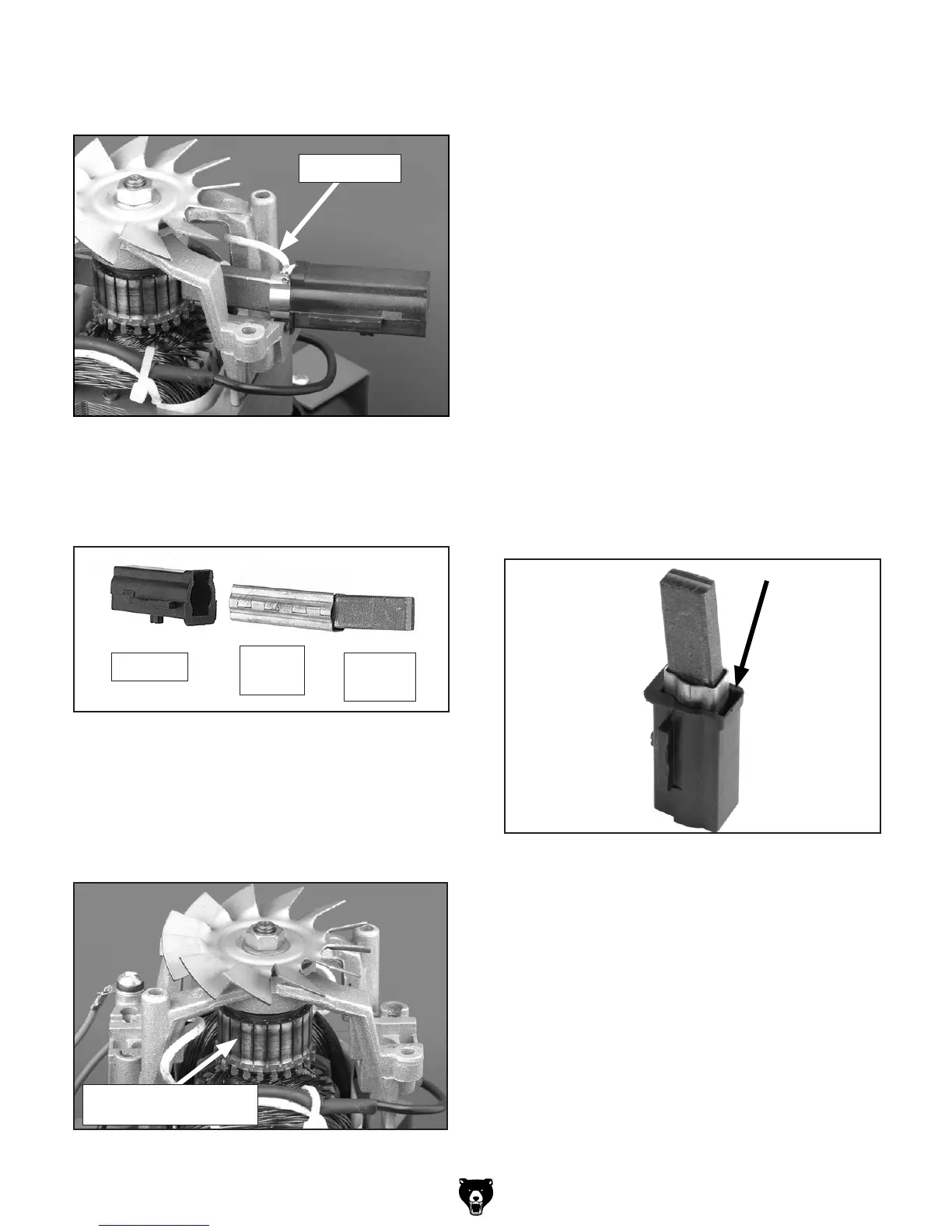

6. Lift each brush housing out of its seat and

unplug the power wire (Figure 35).

Figure 35. Brush housing removal.

Power Wire

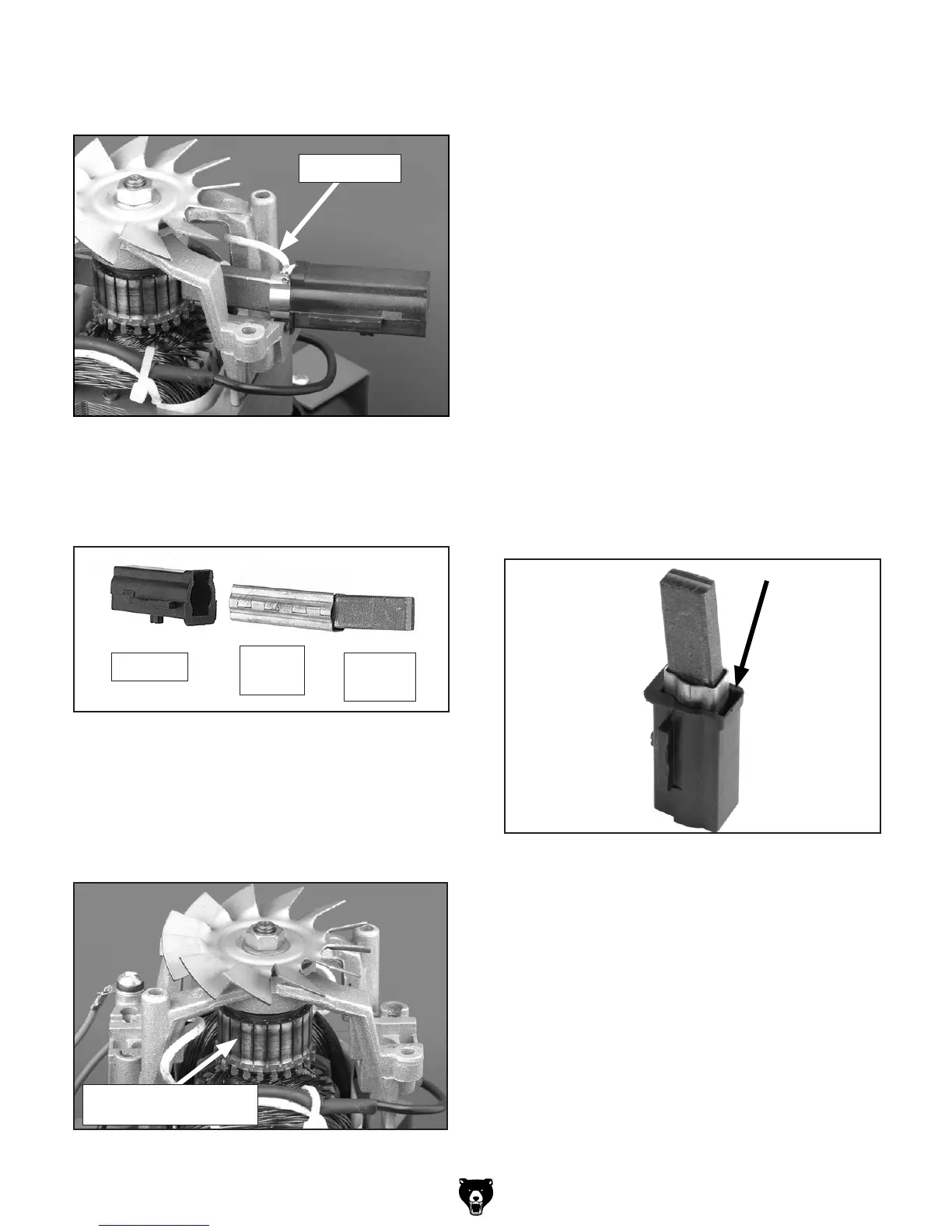

7. Slide the brush assembly apart, clean the

housings and brass sleeves with mineral spir-

its, and allow the parts to dry (Figure 36).

Figure 36. Brush assembly.

8.

Reassemble the housings with the brass

sleeves and the new carbon brushes (Figure

36) and set aside.

9.

Inspect the commutator surface (Figure 37).

Housing

Brass

Sleeve

Carbon

Brush

—If the brushes have worn deep grooves in

the commutator, we recommend replacing

the motor. Typically the labor involved with

re-turning the commutator on a lathe and

then undercutting the insulator segments

far exceeds the price of a new motor.

—If the commutator only has minor wear and

black-colored carbon tracking (Figure 37),

use a fine crocus cloth to polish the com-

mutator where the brushes ride. DO NOT

use emery cloth or sandpaper to clean

the commutator or you will make it out-of-

round, which will cause the new brushes to

arc, overheat, and wear out quickly.

Finish the cleaning process by using acetone

and a cotton rag to wipe off any oils or con-

taminants from the commutator.

10.

Insert the power wire spade terminal into the

brush assembly between the brass sleeve

and the housing (Figure 38).

Figure 37. Commutator.

Insert Power Wire Spade Terminal Here.

Figure 38. Brush power lead location.

Carbon Tracking on

Commutator Surface

Loading...

Loading...