3 OM-EE-20 & 40 (CE) INTERNATIONAL

The unit will arrive in a heavy wooded crate and will be bolted or banded to a skid.

Immediately upon receipt, inspect the carton carefully for exterior damage.

Carefully cut any polyester straps around the carton and detach the sides of the

box from the skid. Pull the carton up off the unit.

Thoroughly inspect the unit for concealed damage. Report any shipping damage or

incorrect shipments to the delivery agent.

Write down the model number, serial number, and installation date, and retain this

information for future reference. Space for these entries is provided at the top of

the Service Log at the back of this manual. Keep this manual on file and available

for operators to use.

When installation is to begin, carefully cut any straps which hold the unit on the

skid. Lift the unit straight up off the skid. Examine packing materials to be sure

loose parts are not discarded with the materials.

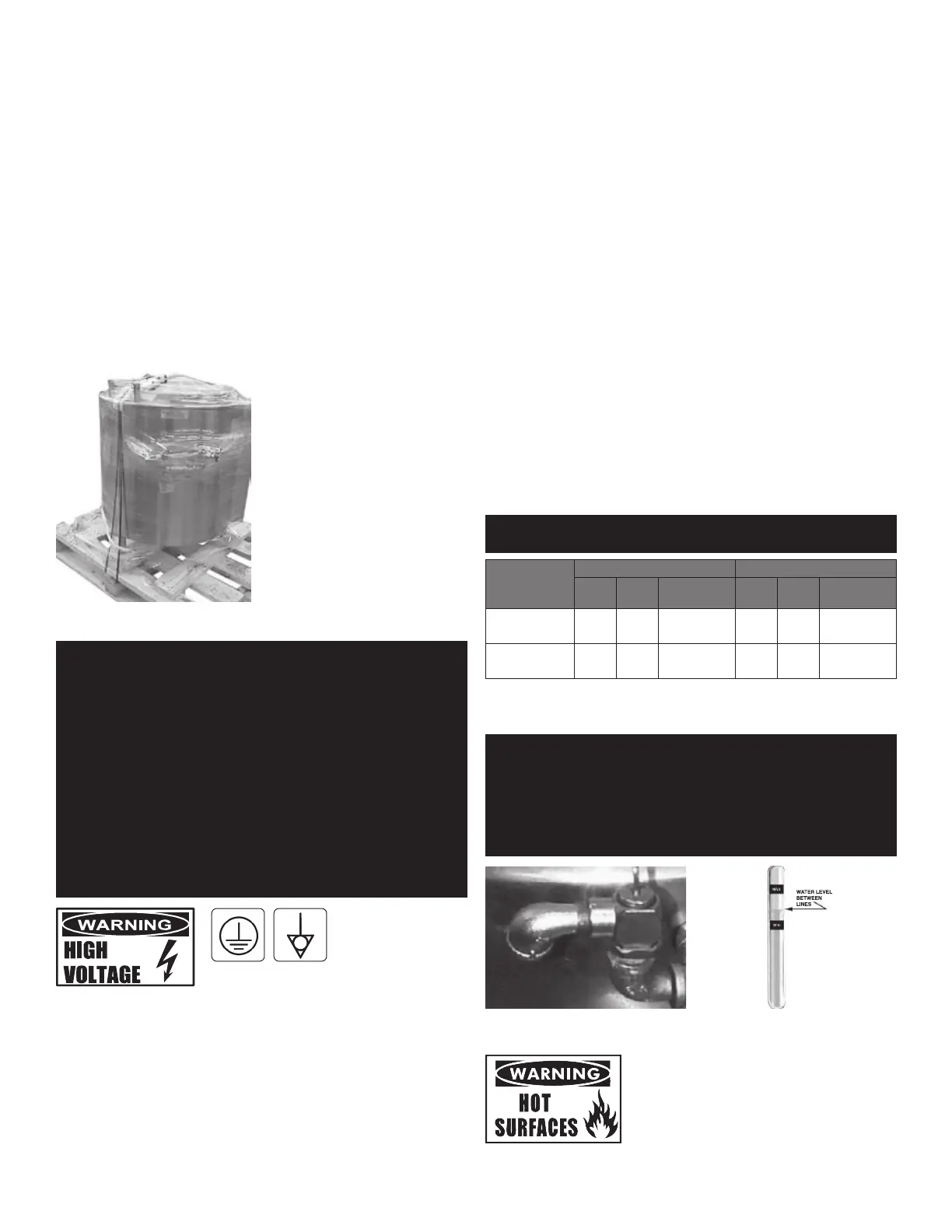

Once the kettle is unpacked, the tangent draw-off valve is easily attached, as

shown above. The large nut which attaches the valve to the kettle should be hand

tightened only.

INSTALLATION

WARNING: INSTALLATION OF THE KETTLE MUST BE DONE BY A CERTIFIED

ELECTRICIAN OR AUTHORIZED REPRESENTATIVE QUALIFIED TO WORK

WITH ELECTRICITY. IMPROPER INSTALLATION CAN RESULT IN INJURY TO

PERSONNEL AN/OR DAMAGE TO EQUIPMENT.

DANGER: ELECTRICALLY GROUND THE UNIT AT THE TERMINAL PROVIDED. FAILURE

TO GROUND UNIT COULD RESULT IN ELECTROCUTION AND DEATH.

CAUTION: BEFORE ANY ELECTRICAL CONVERSION, VERIFY THAT THE BRANCH

CIRCUIT WIRING IS ADEQUATE TO HANDLE ANY INCREASE AMPERAGE

REQUIREMENTS. REFER TO THE ELECTRICAL SPECIFICATIONS LISTED

BELOW.

WARNING: DO NOT CONNECT ANY PIPING TO THE PRESSURE RELIEF VALVE. THE VALVE

MUST BE FREE TO VENT STEAM AS NEEDED. IMPROPER INSTALLATION

WILL VOID THE WARRANTY! THE ELBOW ATTACHED TO THE SAFETY VALVE

MUST POINT TO THE FLOOR. INSTALLATION WILL VOID THE WARRANTY!

THE ELBOW ATTACHED TO THE SAFETY VALVE MUST POINT TO THE FLOOR.

The kettle is provided with complete internal wiring and is ready for immediate

connection. Wiring diagrams are provided in this manual and on the inside of

the control housing service panel. Any mechanical or electrical changes must be

approved by the Food Service Engineering Department.

The completed unit has been operated at the factory to test all controls and heater

elements.

1. Set the kettle in place and level it by turning the bullet feet to adjust leg length.

Allow clearance around the unit for cleaning, maintenance and

service.

2. Confirm that the jacket water level is at the mid point of sight glass. If the level

is low, follow the instructions under “Jacket Filling and Water Treatment,” in

this manual.

3. The open end of the elbow on the outlet of the pressure relief valve must face

downward. If it does not, turn it to the correct position.

4. Provide electrical power specified on the equipment electrical information

plate.

5. Bringing the electrical service through the entrance at the rear of the support

housing with 1-1/4” (35 mm) conduit, making a watertight connection with the

incoming lines.

6. Electrically protective earth ground the unit at the terminal provided (figure 1).

7. This unit is fitted with an equipotential terminal in accordance with national

regulations and CE directives. Locate this marking for equipotential terminal

connection (figure 2).

8. Check the following to confirm that your kettle is properly installed:

• Room for cleaning and servicing

• The kettle is level

• The correct amount of water is in the kettle jacket

• Pressure relief valve is pointed down

• Unit is connected with a waterproof supply of the proper voltage, phase

and amperage rating

ELECTRICAL SPECIFICATIONS

WARNING: USE COPPER WIRE RATED AT LEAST 75ºC (UNDER “ELECTRICAL

SPECIFICATIONS”).

Voltage/Phase

EE-20 EE-40

kW Amps Min. Wire Gauge kW Amps Min. Wire Gauge

230 V olt

Single-Phase

11 57

10 AWG

(6 mm

2

)

21 96

4 AWG

(24 mm

2

)

400 V olt

3-Phase

12 57

14 AWG

(2.5 mm

2

)

24 96

10 AWG

(6 mm

2

)

INITIAL START-UP

IMPORTANT: BE SURE ALL OPERATORS READ, UNDERSTAND AND FOLLOW THE OPERATING

INSTRUCTIONS, CAUTIONS, AND SAFETY INSTRUCTIONS CONTAINED IN THIS

MANUAL.

WARNING: AVOID ALL DIRECT CONTACT WITH HOT SURFACES. DIRECT SKIN CONTACT

COULD RESULT IN SEVERE BURNS. AVOID ALL DIRECT CONTACT WITH HOT

FOOD OR WATER IN THE KETTLE. DIRECT CONTACT COULD RESULT IN SEVERE

BURNS.

The open end of the pressure relief valve

elbow must face downward.

Correct water level.

Now that the kettle has been installed, you should test it to ensure that the unit is

operating correctly.

Figure 2Figure 1

Loading...

Loading...