7 OM-EE-20 & 40 (CE) INTERNATIONAL

SEQUENCE OF OPERATION

The following “action-reaction” outline is provided to help understand how the

kettle works.

When the operator starts up the kettle by turning the power switch “ON” and

heat knob from 0 to a desired setting, the control relay closes. This lights up the

heating indicator light and causes the contactors to close, allowing power to flow

to heating elements.

When the temperature of the steam jacket reaches the value corresponding to

the heat setting, the control relay opens. This turns off the heating indicator light

and causes the contactors to open, stopping the power to the heaters.

As soon as the controller senses that the kettle is cooling below the set point, the

control relay closes, the heating indicator light comes on, the contactors close,

and the heaters come on again. On-off cycling continues, keeping the kettle at

the set temperature.

This is why the heating indicator light cycles on and off during normal operation.

Every time the kettle is tilted, the tilt cut-off switch interrupts the power supply to

the heaters, so that the heating elements will not operate while not submerged

in the jacket water.

If steam pressure greater than 30 psi (206 kPa, 2.06 bar) is generated in the

jacket, the safety valve will open and relieve the excess pressure.

If the jacket water level gets too low before the heating elements overheat, the high-

limit control will open and shut off power to the elements until the kettle cools.

Setting the power switch dial to 0 shuts down all control and heating circuits.

The kettle has the following safety features:

1. Low water cutoff relay that will remove power from control and contactors

until the jacket water level is corrected.

2. High limit pressure switch, set to open at about 24 psi (165 kPa, 1.65 bar)

and to shut down the heat until jacket pressure is decreased.

3. Pressure relief valve, which will release steam if jacket pressure exceeds 30 psi

(206 kPa, 2.06 bar)

4. Tilt switch, which shuts off all heat when the kettle is tilted.

REPLACEMENT PARTS

To order parts, contact your Authorized Service Agent. Supply the model

designation, serial number, part description, part number, quantity, and when

applicable, voltage and phase.

CONTACT US

If you have questions pertaining to the content in this manual, contact Unified

Brands at 888-994-7636.

TROUBLESHOOTING

This unit is designed to operate smoothly and efficiently if properly maintained.

However, the following is a list of checks to make in the event of a problem.

Wiring diagrams are found at the end of this manual. When in doubt, turn unit

off and call for service at 888-994-7636. If an item on the check list is marked

with (X), it means that the work should be done by an Authorized Service Agent.

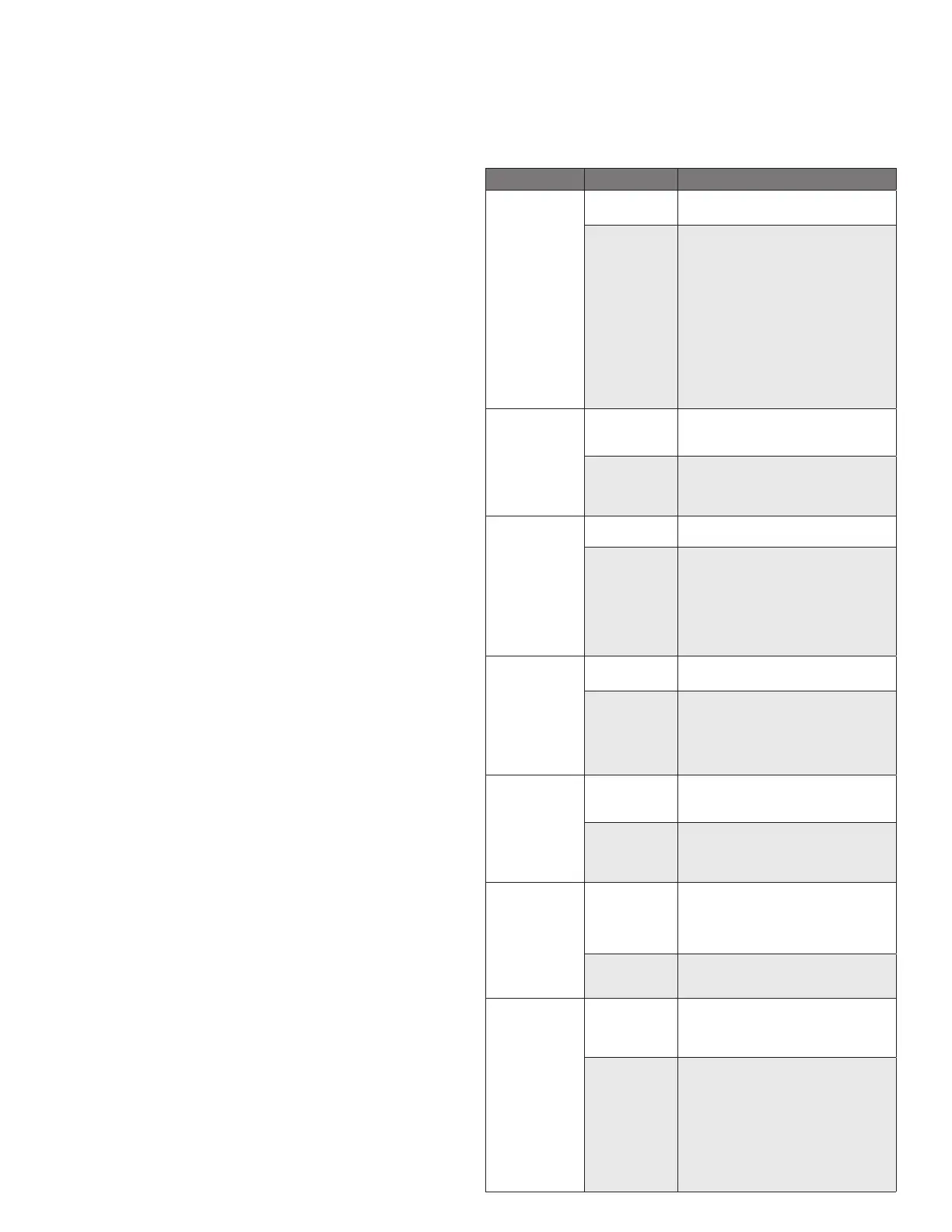

SYMPTOM WHO WHAT TO CHECK

Kettle will not

heat and heating

indicator will not

come on.

User a. Electric power supply to the unit.

b. Water level in jacket.

Authorized

Service Rep Only

c. Control circuit fuses in the control console.

X

REPLACE BLOWN FUSES ONLY WITH A

FUSE OF

THE SAME AMP RATING. A HIGHER RATED

FUSE

WILL NOT PROTECT THE UNIT OR THE

BUILDING.

d. For loose or broken wires. X

e. Operation of variable thermostat. X

f. Low water cutout switch. X

g. Water probe. X

h. That high limit pressure switch is closed.

X

Kettle will not

heat but heating

indicator comes

on.

User a. For air in the jacket. See “Jacket

Vacuum” in the “Maintenance” section of

this manual.

Authorized

Service Rep Only

b. Contactor. X

c. Heater elements with ohmmeter for

ground short or open element. If element

is defective, call Groen. X

Kettle continues

heating after

it reaches

the desired

temperature.

User a. Thermostat dial setting.

Authorized

Service Rep Only

b. Thermostat circuit for short. X

c. Thermostat calibration. X

d. Thermostat operation. The thermostat

should click when the dial is rotated to

settings above and below the temperature

of the kettle. X

e. Contactor, to determine whether it is

energized or stuck. X

Kettle stops

heating before

it reaches

the desired

temperature.

User a. Thermostat dial setting.

b. Jacket water level.

Authorized

Service Rep Only

c. Thermostat calibration. X

d. Thermostat operation. The thermostat

should click when the dial is rotated

above and below the setting for the

temperature of the kettle. X

e. Pressure limit the switch. X

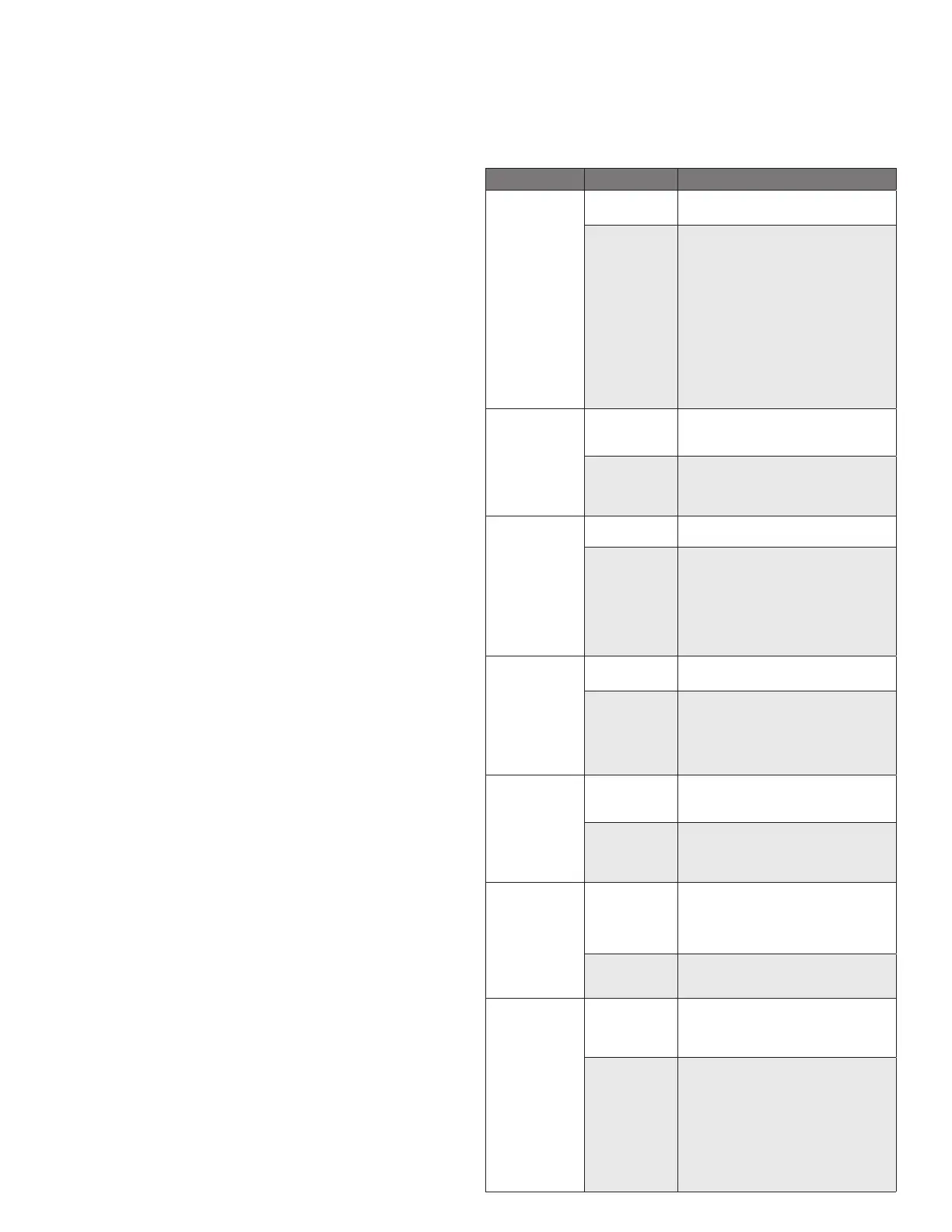

Kettle heats

slowly.

User a. For air in the jacket. See “Jacket

Vacuum” in the “Maintenance” section of

this manual.

Authorized

Service Rep Only

b. Heater elements with ohmmeter for

ground short or open element. If an

element is defective, call Groen. X

c. Voltage of main power source. X

Safety valve leaks

a small amount of

steam when the

kettle is operating.

User a. For contamination that prevents seating of

valve. With full pressure in the jacket, pull

the lever all the way briefly to blow the

valve clean, then let the lever snap back

to seat the valve.

Authorized

Service Rep Only

b. Safety valve for defects. Replace any

defective valve with an identical valve. X

Safety valve pops. User a. For air in the jacket. See “Jacket Vacuum”

in the Maintenance section of this manual.

b. Whether kettle was being heated empty

when valve popped.

Authorized

Service Rep Only

c. Pressure limit switch. X

d. Thermostat operation. Thermostat should

click when the dial is rotated above and

below the setting for the temperature of

the kettle. X

e. Safety valve. If the valve pops at

pressures below 196 kPa (28 psi), replace

it. X

f. Contactor, to determine whether it is de-

energized. X

Loading...

Loading...