Dismantling Procedures CR, CRN 32•45•64•90

58

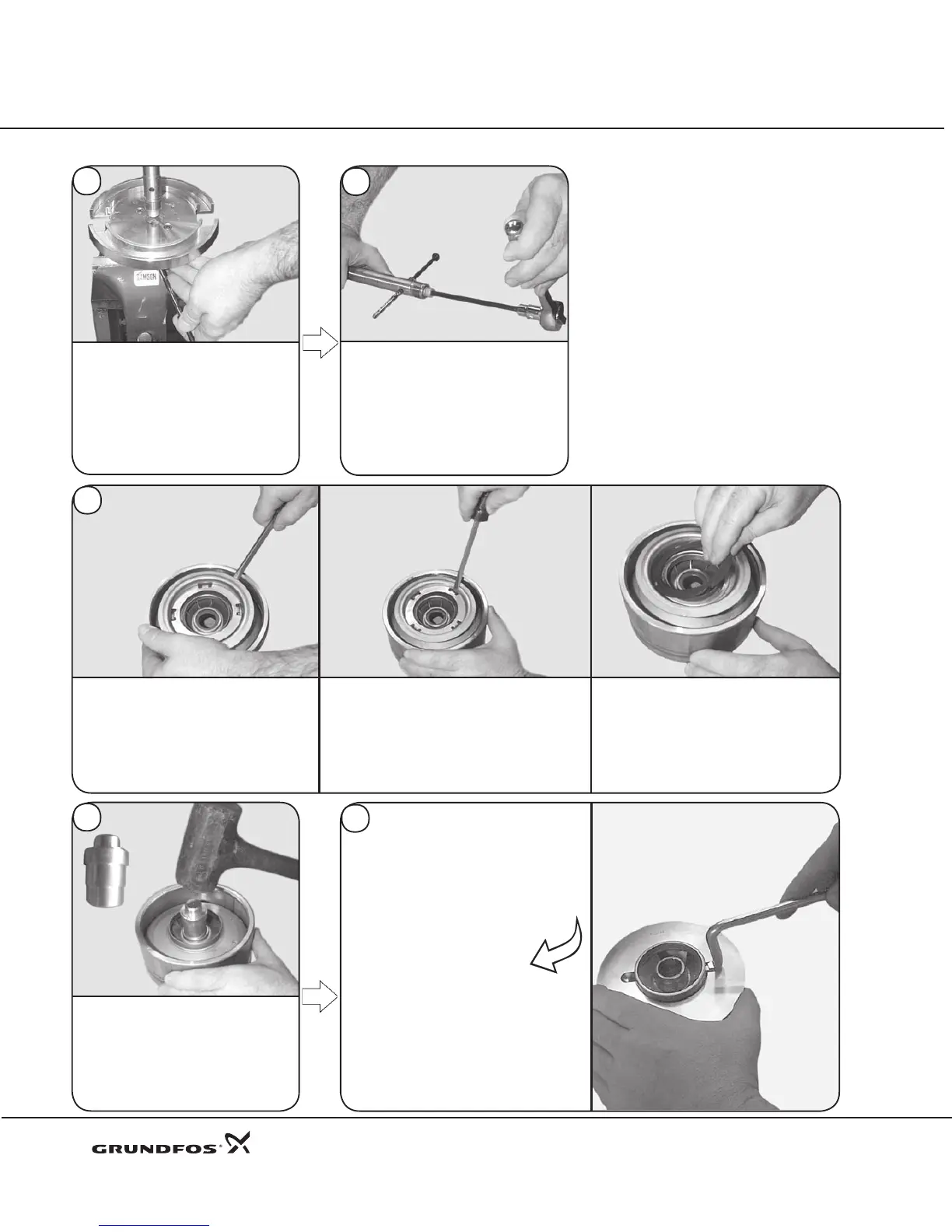

To remove the shaft from the

assembly/disassembly tool, remove

the holding pin from the shaft and

lift shaft out of tool.

After inspecting the parts, if further

disassembly is required, proceed to

the next steps.

59

Remove bearing from shaft. Remove

6 mm hex socket Allen Screw (Pos. 67),

locking washers (Pos. 66b), washer

(Pos. 66), and journal bearing (Pos. 47b).

Loosening the allen screw may require

use of the holding pin as a countering

device so the shaft does not spin.

Depending on wear, the Neck Ring (Pos. 45),

Retainer (Pos. 65), and Holder (Pos. 45a)

may need to be removed. Using a at bar,

pry these components out of the chambers

and base interface as a complete assembly.

If wear or damage is minor, the neck

ring may be replaced using a screw-

driver to twist and pry out the retainer.

Lift out the Neck Ring (Pos. 45).

60

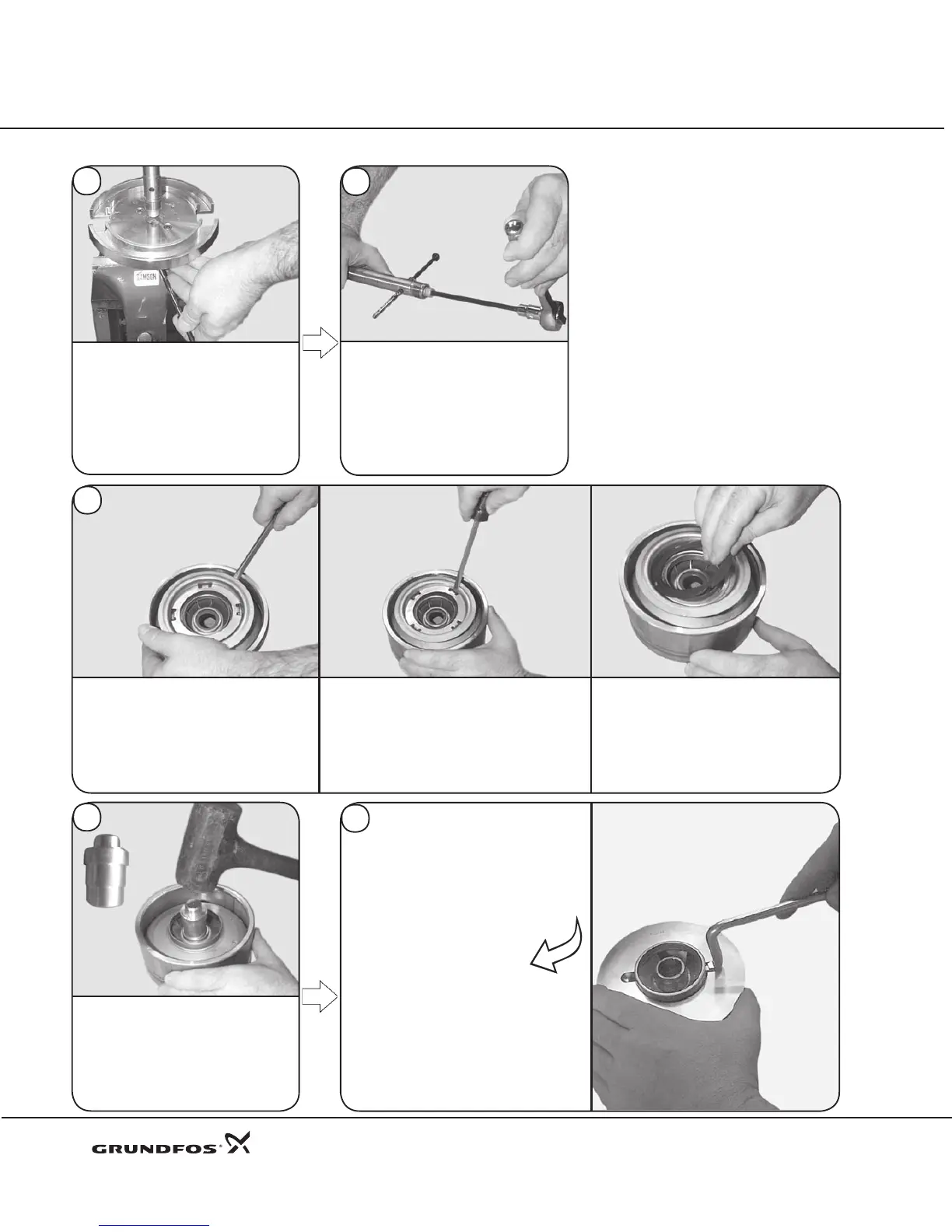

To r e m o v e t h e C h a m b e r

Bearing (Pos. 47), Bearing Sleeve

(Pos. 47c), and Bearing Lock Ring

(Pos. 47d), place chamber upward

using the punch (00SV0015).

Drive the bearing downward.

61

62

If the Impeller Wear Ring (Pos. 49c) is

worn and the split cone nut/impeller

hub threads are not damaged, the

wear ring may be removed using

the app ropria te suppo rt t oo l,

• CR, CRN32 00SV0043

• CR, CRN45 00SV0044

• CR, CRN64 00SV0045

• CR, CRN90 00SV0046

along with the wear ring puller

(00SV0239) used to pry off the wear

ring. If the threads of the impeller hub are

damaged, a new impeller will be required.

10

Punch

Loading...

Loading...