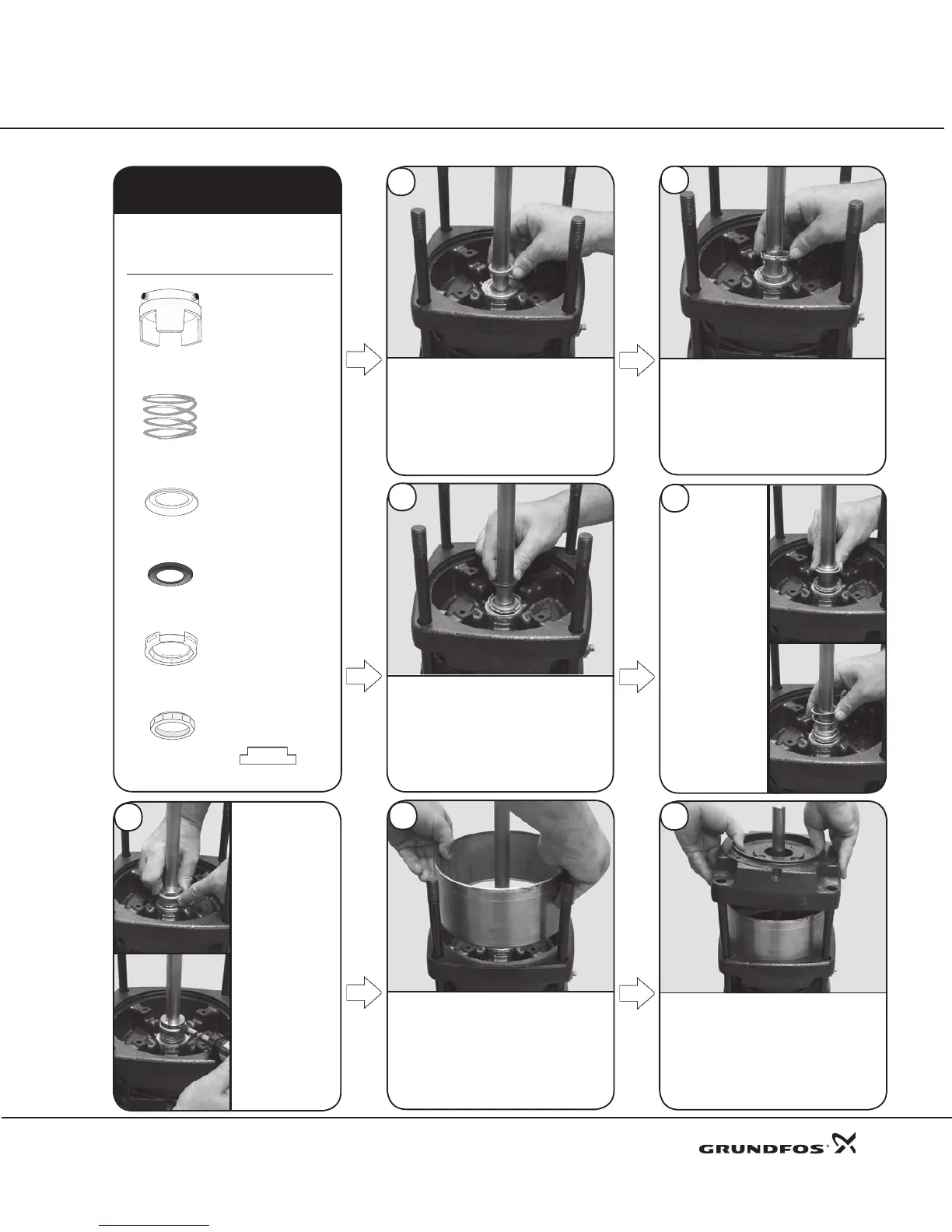

Pos. 112

Seal Driver with set

screws, Pos. 113

Pos. 108

Spring

Pos. 106

Cup for O-ring and

Spring

Pos. 107

O-Ring

Pos. 111

Floating Seal Driver

Pos. 104

Rotating Seal Face

(The tapered face should point

upward through the driver 111

and press against the O-ring

107).

LOWER COMPONENTS OF

SEAL ASSEMBLY

COMPONENTS OF ROTATING SEAL

Reassembly Procedures CR, CRN 32•45•64•90

Back-to-Back Seal (continued)

39

With the tapered edge facing upward,

lower the Rotating Seal Face (Pos. 104)

down onto the stationary seal face.

40

Lower the Floating Seal Driver

(Pos. 111) until it fully engages

the rotating seal face. Ensure

the taper of the rotating seal

p r o t r u d e s t h ro u g h d r i v e r.

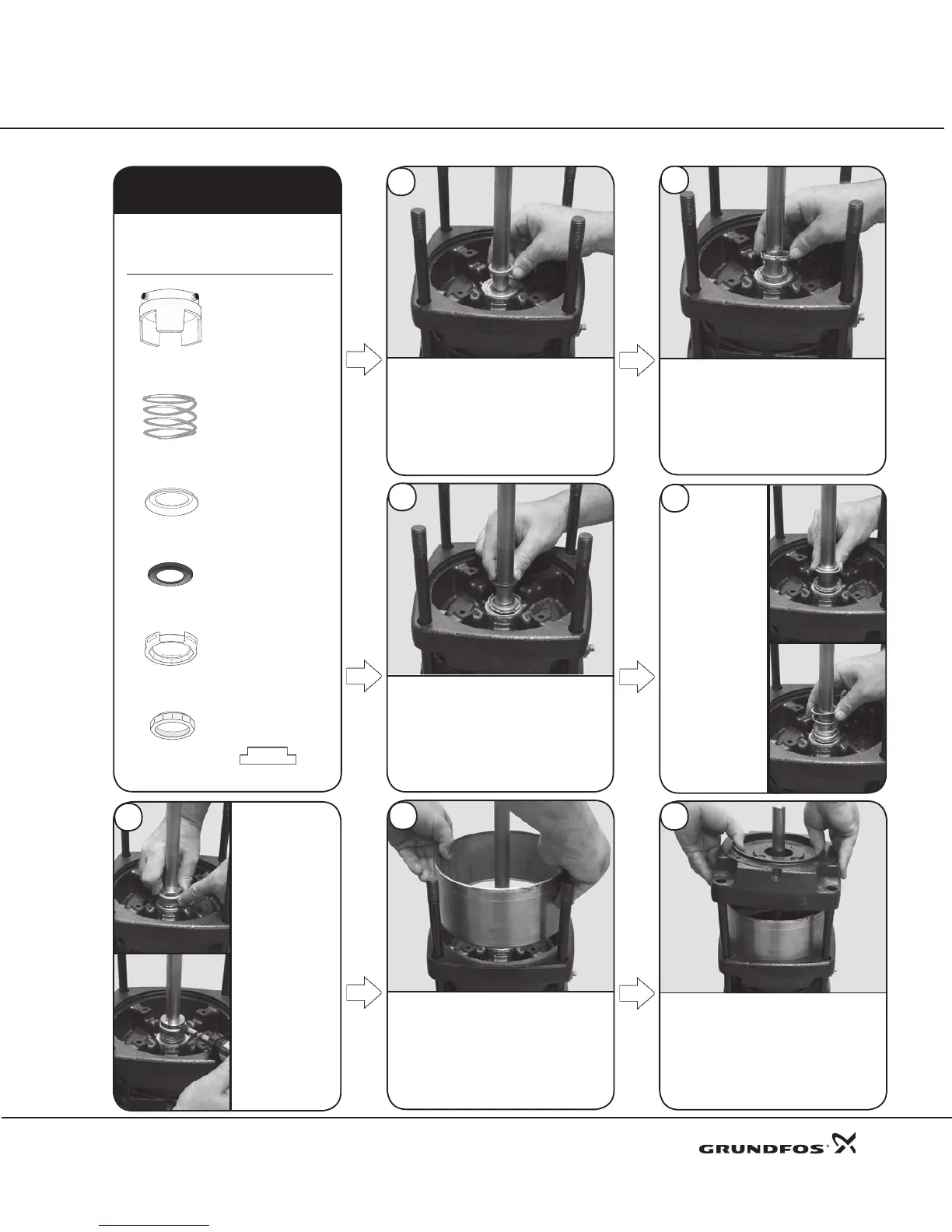

Lower and seat the upper Sleeve

(Pos. 55a) into the middle pump head.

44

43

45

Lower and rmly seat the uppermost

Pump Head (Pos. 2b) onto the

upper sleeve. Proceed to step 46.

19

41

Lubricate the inner surface of the

O-ring (Pos. 107) with Rocol, Dow

Corning 111, or soapy water. Slide the

O-ring down the shaft until it contacts

both the driver and the protruding

surface of rotating seal face.

42

Lower the

Cup (Pos. 106)

over the O-ring.

Lower the

Spring

(Pos. 108) until

it ts over the

cup.

Lower the Driver

(Pos. 112) with

set screws

(Pos. 113).

Driving tabs

should pass and

engage each

other. With the

shaft and the

seal drivers

pushed down as

far as possible,

tighten the

3mm Set Screws

(Pos. 113) to

10ft.-lbs./13Nm.

Loading...

Loading...