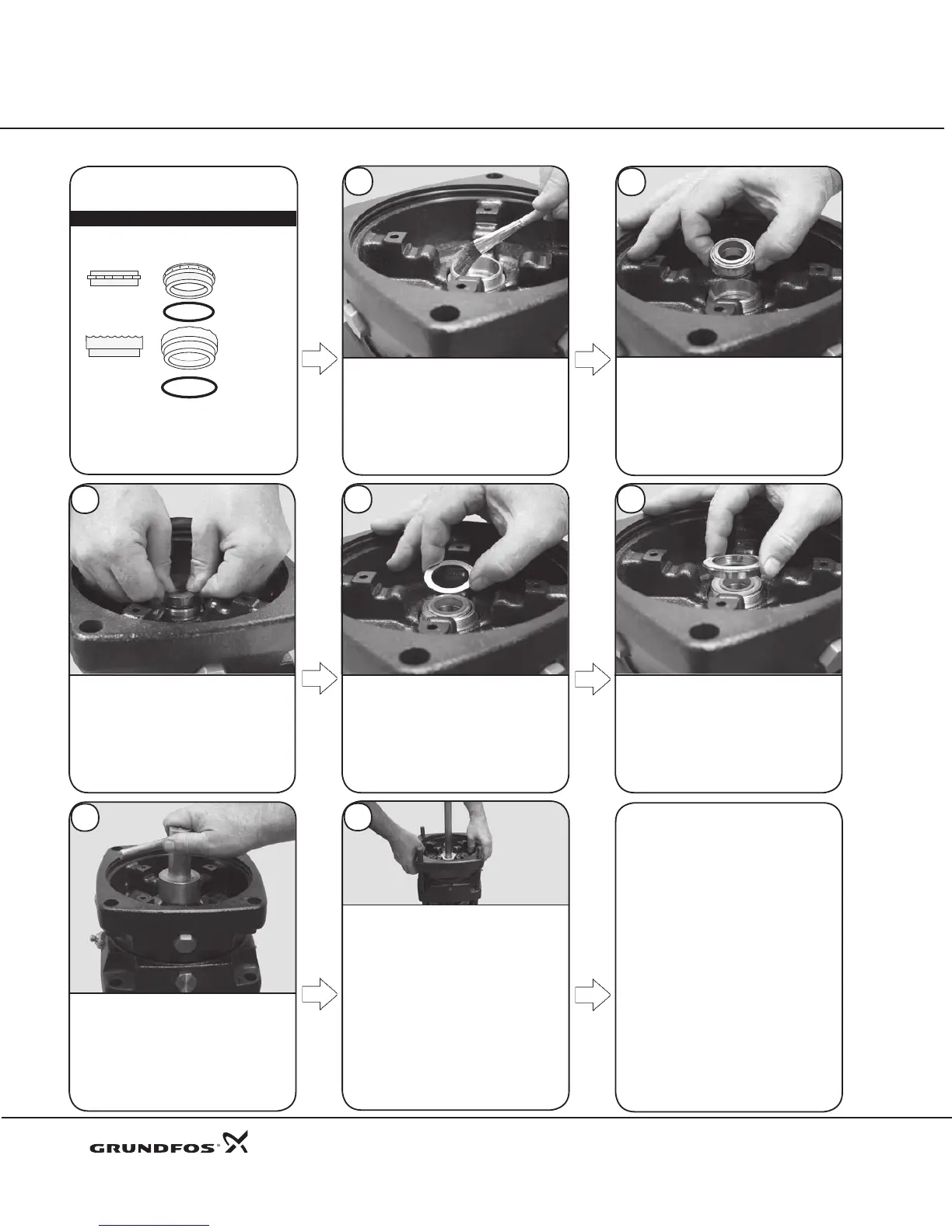

COMPONENTS OF

STATIONARY SEAL

Pos. 103

Upper Seal

Ring

Pos. 102a

O-Ring

Pos. 103a

Retainer

For Upper

Seal Ring

Pos. 102

O-Ring

"N" PUMPS AND MODEL B

Side View

Side View

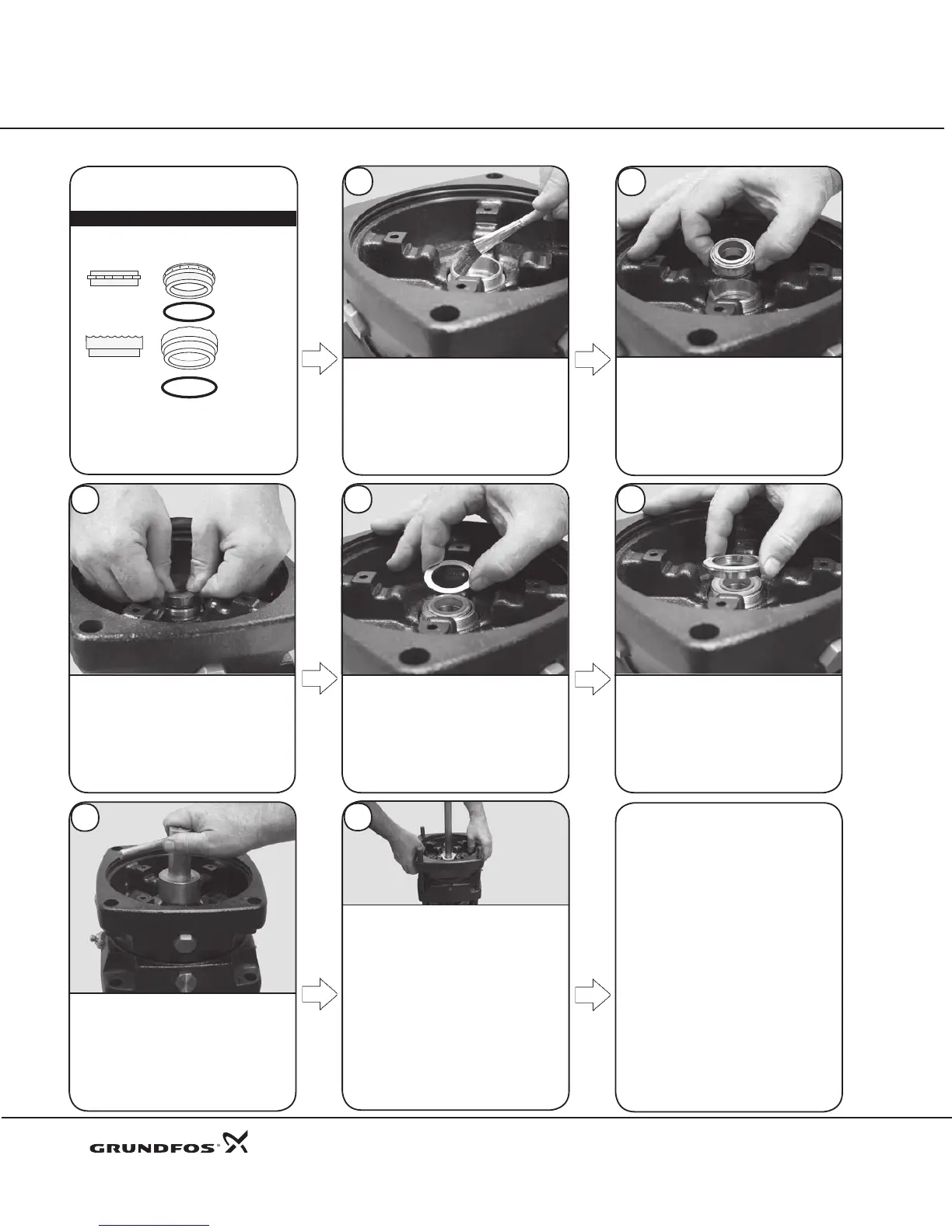

Use special tool 00SV7902 to tighten

the nut.

Reassembly Procedures CR, CRN 32•45•64•90

Back-to-Back Seal (continued)

Lubricate the inner surface of

the connecting pipe with Rocol,

Dow Corning 111, or soapy

water. Lubricate the threads with

Gardolube or an equivalent FDA

approved non-toxic lubricant.

32

Press the stationary seal assembly

i n t o th e co n n e c t i n g p i p e .

Clean the polished seal face

surface with an alcohol wipe.

34

18

Loosely thread the Securing Nut

(Pos. 148) onto the connecting pipe.

36

The order of assembly

for the rotating portion

of the seal can be seen

on the next page.

To prevent leakage,

it is critical to position

the rotating seal

face correctly.

37

When reusing an existing shaft, rst

clean any set screw marks off the shaft

with a light grit emery cloth before

proceeding with the next step. Then,

lift the complete assembly (lowermost

pump head, spacing ring, middle pump

head, and complete stationary seal) by

the lowermost pump head. Make sure

the Priming Vent Plug (Pos. 18) on the

lowermost pump head is inline/over the

discharge port of the suction/discharge

base. Carefully lower the assembly down

the shaft and staybolts. Firmly seat the

assembly in place onto the sleeve.

38

Lower and press the completed

s t a t i o n a r y s e a l a s s e m b l y

i nt o t h e co n n e c t i n g pi p e .

33

Place the Retaining Washer (Pos. 59a)

onto the seal.

35

Loading...

Loading...