English (US)

30

18. Emergency operation (only 15-30 hp)

If the pump is stopped and you cannot start the pump

immediately after normal remedies, the reason could be a faulty

frequency converter. If this is the case it is possible to maintain

emergency operation of the pump.

Before change over to emergency operation we recommend you

to:

• check that the power supply is OK

• check that control signals are working (start/stop signals)

• check that all alarms are reset

• make a resistance test on the motor windings (disconnect the

motor leads from the terminal box).

If the pump remains stopped it is possible that the frequency

converter is faulty.

To establish emergency operation proceed as follows:

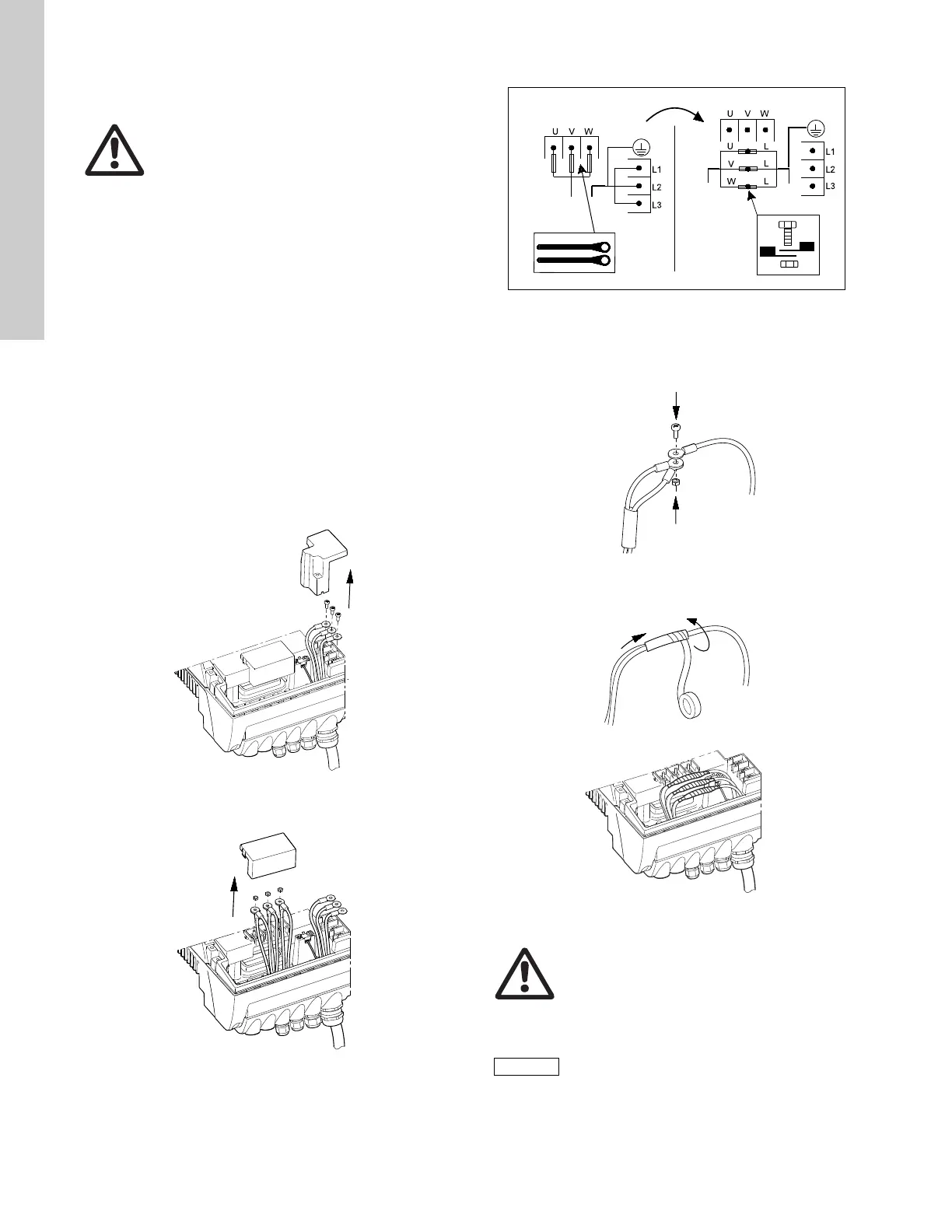

1. Disconnect the three power supply leads, L1, L2, L3, from the

terminal box, but leave the protective ground lead(s) in

position on the PE terminal(s).

2. Disconnect the motor supply leads, U/W1, V/U1, W/V1, from

the terminal box.

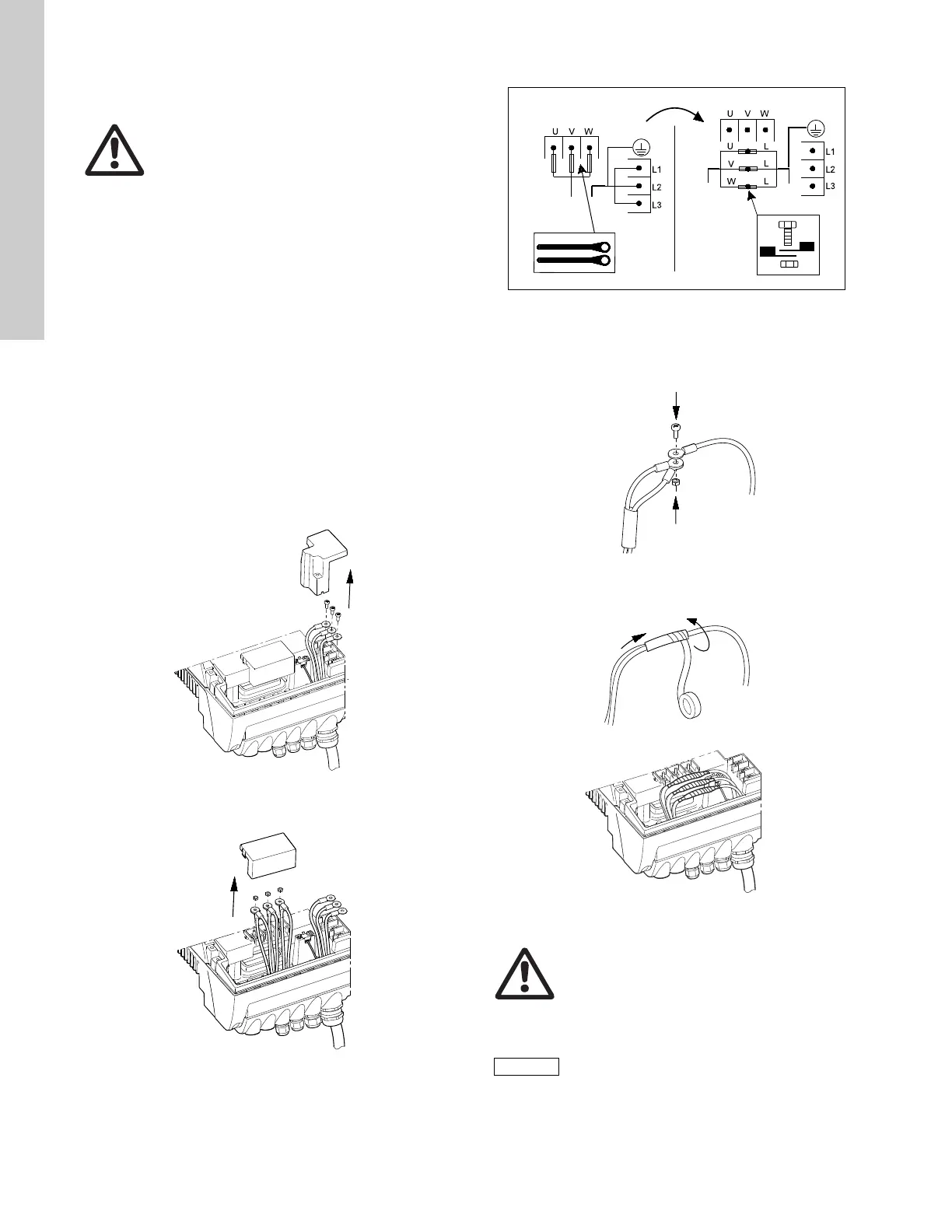

3. Connect the leads as shown in fig. 42.

Fig. 42 How to switch an E-pump from normal operation to

emergency operation

Use the screws from the power supply terminals and the nuts

from the motor terminals.

4. Insulate the three leads from each other by means of

insulating tape or the like.

5. A motor starter is required.

Warning

Never make any connections in the pump

terminal box unless all electric supply circuits

have been switched off for at least 5 minutes.

Note for instance that the signal relay may be

connected to an external supply which is still

connected when the power supply is

disconnected.

TM03 8607 2007TM03 9120 3407

TM04 0018 4807TM03 9121 3407TM03 9122 3407

TM03 9123 3407

Warning

Do not bypass the frequency converter by

connecting the power supply leads to the U, V

and W terminals.

This may cause hazardous situations for

personnel as the high voltage potential of the

power supply may be transferred to touchable

components in the terminal box.

Check the direction of rotation when starting up

after switching to emergency operation.

Loading...

Loading...