English (GB)

8

6.3 Pump identification

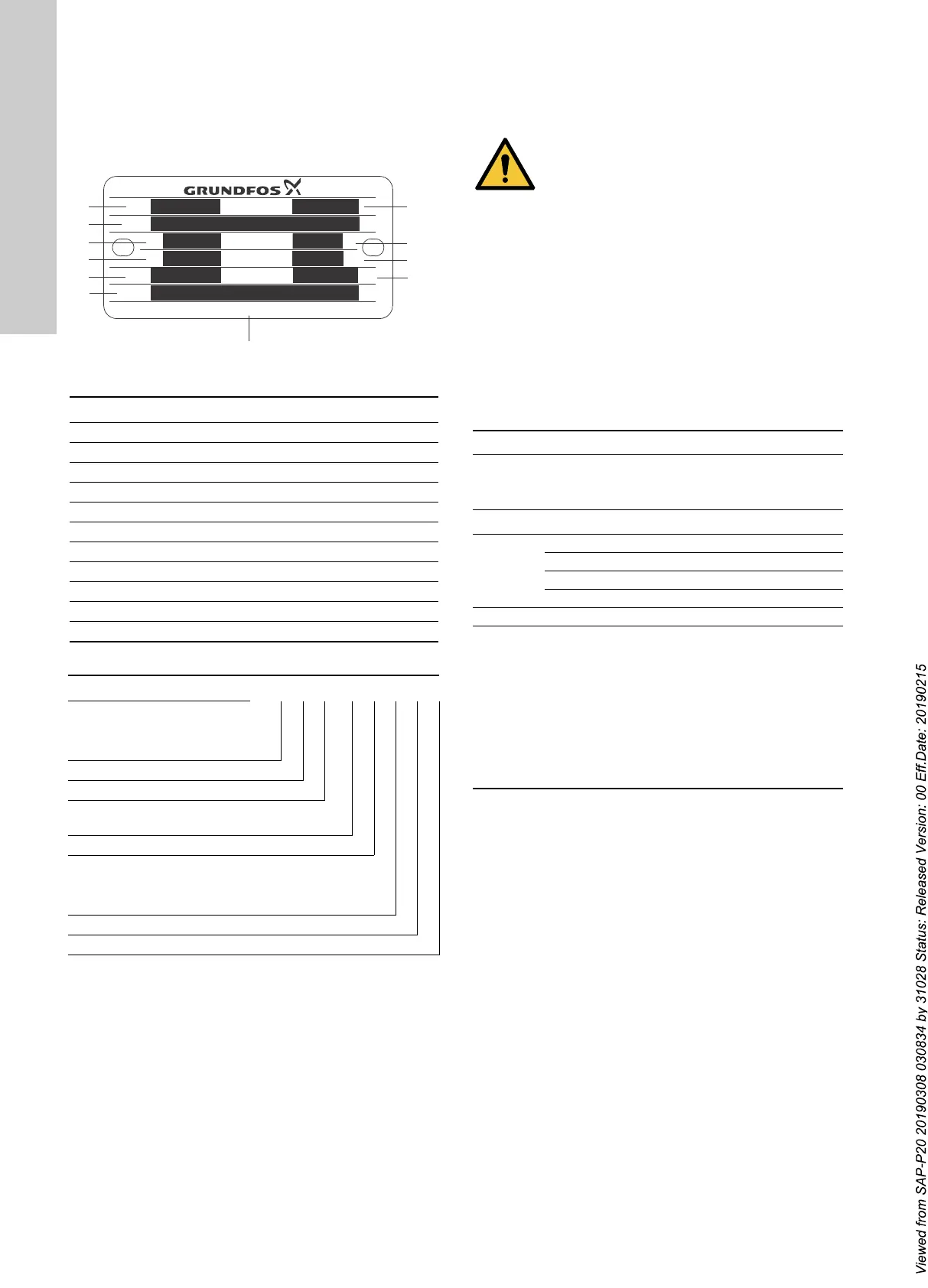

6.3.1 Nameplate

All pumps are identified by catalogue and serial numbers. These

numbers are stamped on the pump nameplate, as shown in fig. 6,

affixed to the pump housing. Refer to these numbers in all

correspondence with Grundfos.

Fig. 6 Nameplate of CVM, CHM pumps

6.3.2 Type key

* X material code is made according to customer requirement or

with special construction for different application.

7. Servicing the product

7.1 Maintaining the product

7.2 Lubricating the product

7.2.1 Lubricating the motor

Always follow the motor manufacturer's lubricating instructions, if

they are available, and periodically check grease fittings and

drain plugs for leaks. If the lubricating instructions are not

available, refer to the table below for recommended lubricating

intervals.

• The motor can be lubricated both when it is running or when it

is stopped.

Remove the grease drain plug, if any, and filler plug on the

grease fitting. Grease with clean lubricant until grease

appears at the drain hole or along the motor shaft.

One-half to one cubic inch (0.5

3

- 1

3

inch) of grease is sufficient

for motors of 4 kW and lower, with proportionately more grease

for bigger kW motors.

Most fractional and some integral frame motors have

"sealed-for-life" bearings, and do not require further lubrication

throughout motor life.

The table Approved grease lubricants in section 7.2.2 Lubricating

the pump lists the recommended types of grease for both pump

and motor lubrication. These grease types have all been

thoroughly tested and must be used whenever possible.

TM07 3130 5218

Pos. Description

1 Product number

2 Serial number

3 Type designation (see Type key on page 8)

4 Rated flow rate [m

3

/h]

5 Pump head at rated flow rate [m]

6 Speed of rotation [rpm]

7 Impeller diameter [mm]

8 Pressure rating and maximum temperature

9 Rated motor power [kW]

10 Production date, year-month-date

11 Country of production

Example CVM 5/ 4- B10 (R) H 55 4

Type

CVM: vertical multi-stage pump

CHM: horizontal multi-stage pump

Pump inlet nominal diameter

Number of stages

Material code

(B-10/20., I, N or X*)

Option: with wear ring

Motor power unit (optional)

H: NEMA motor [HP]

None: IEC motor [kW]

Motor power rated x 10

Motor poles

P/N:

Type:

SER#:

Q:

m

3

/h

m

mm

kW

r/min

EDU°C

MAX

P:

H:

IMP DIA:

n:

ST:

DATE:

MADE IN XXXX

1

2

5

7

9

3

4

6

8

10

11

DANGER

Moving machine parts

Death or serious personal injury

- Before any inspection, maintenance, service or

repair of the product, make sure the motor controls

are in the "OFF" position, locked and tagged.

Recommended lubricating intervals

Motor

speed

[rpm]

Motor

power

[kW]

Operating conditions

Standard Severe Extreme

1450 and

below

0.25 - 5.5 3 years 1 year 6 months

7.5 - 30 1-3 years 6 months - 1 year 3 months

37-110 1 year 6 months 3 months

132 and up 1 year 6 months 3 months

above 1450 all kW 6 months 3 months 3 months

Standard conditions:

Operating 8 hours per day, normal or light load, clean air, 37 °C

maximum ambient temperature.

Severe conditions:

Operating continuously 24-hours, shock loads or vibrations, poor

ventilation, 37-65 °C ambient temperature.

Extreme conditions:

Operating continuously, heavy shocks or vibrations, dirt or dust in

the air, extremely high ambient temperature.

Loading...

Loading...