8 | Page 9 | Page

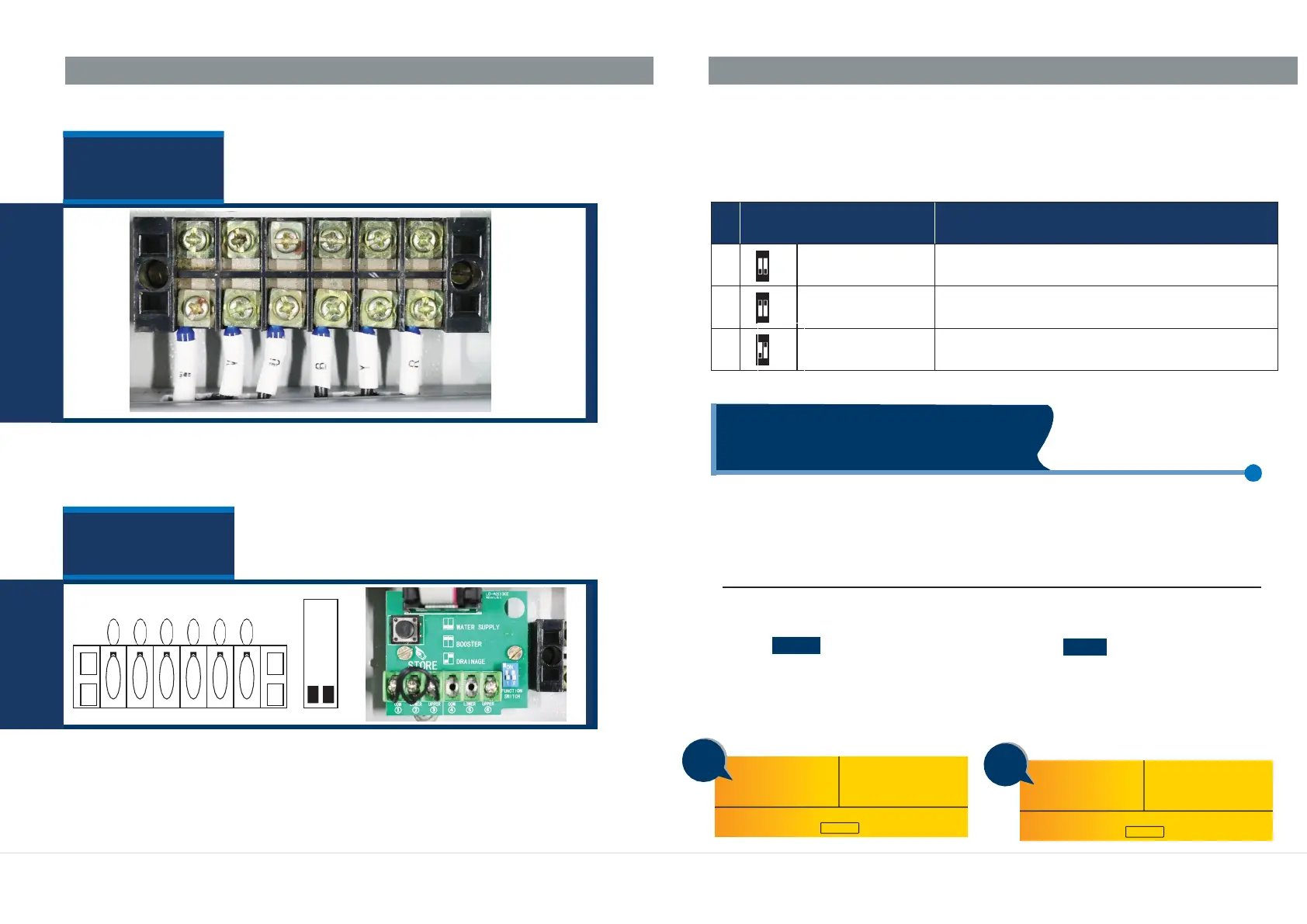

Control terminals

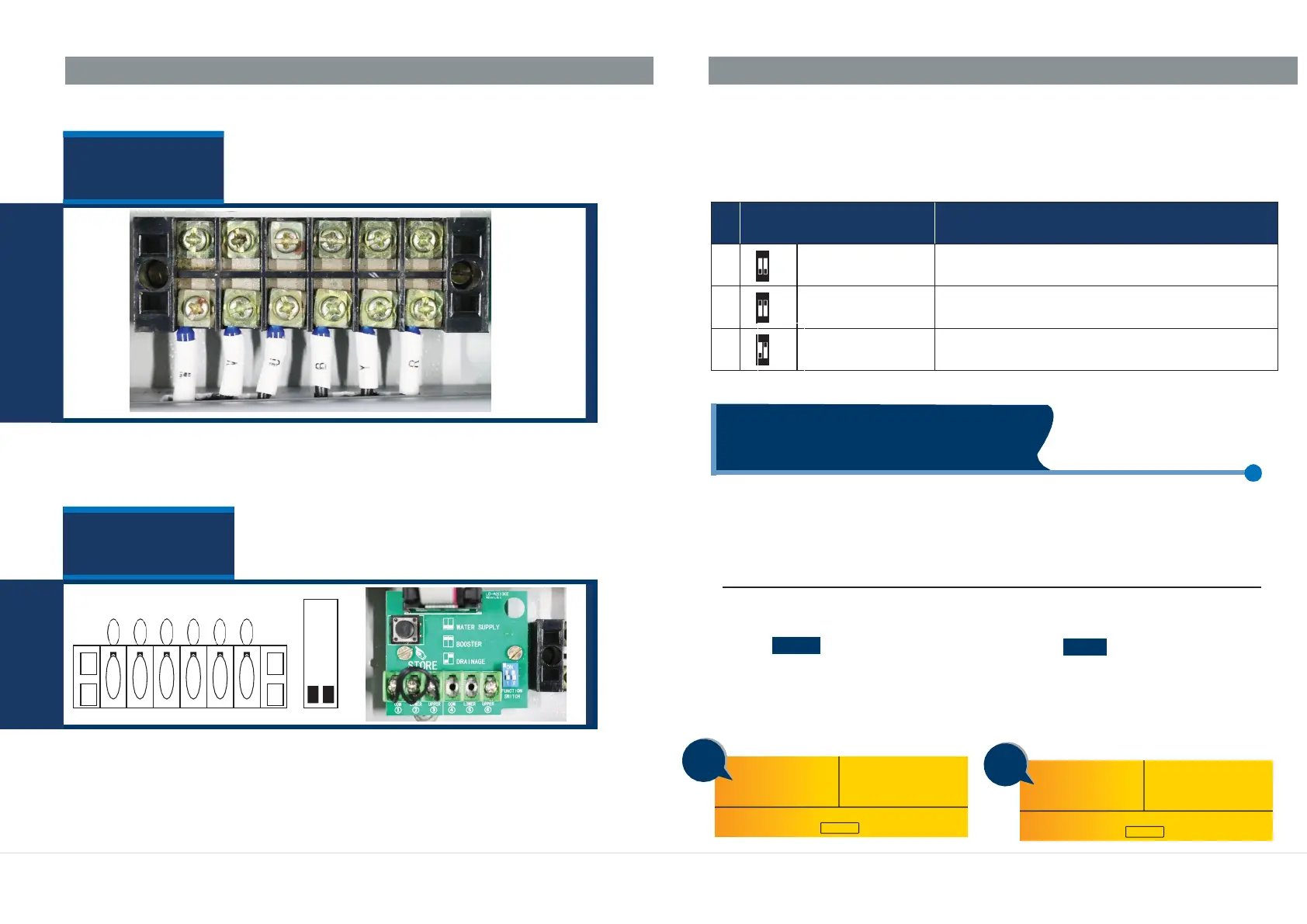

TERMINALS

DIP SWITCH SETTINGS

Users can set the function switch to suit different applications. Before setting

the function switch; the unit should be disconnected from the power supply.

After completing the settings of dip switches, power may be applied to the unit.

Following signs will be displayed in voltage displaying area on the LCD

conforming to the following list.

(a) Power terminals for connecting mains incoming and outgoing

In order to achieve best performance of the controller and for providing

maximum protection to the pump, it is essential that parameter calibration is

done at the time of installation itself or after pump is repaired and installed back.

CALIBRATION:

Setting of parameters (calibration of unit according to the connected load):

X

X

X

X

X

X

(b) Control terminals for connecting probes or float switches

Press the MODE key to switch to manual

mode. Make sure the pump is not running

and LCD screen looks as below

Press the START key to run the pump,

confirm the pump is running OK and drawing

rated current. Also confirm the mains supply

is healthy and incoming voltage is normal,

LCD screen will display voltage and current

being drawn by pump:

A

A

Applied for drainage by liquid level control through

float switch

1

1

1

ON

1 2

3

Applied for water supply by pressure control through

pressure switch & pressure tank

222

ON

1 2

2

Applied for water supply by liquid level control through

probe/float switch

000

ON

1 2

1

ITEM

MESSAGES & IN

VOLTAGE DISPLAYING AREA

SWITCH

POSITION

ITEM

Power terminals

CALIBRATION AND ERASING

Loading...

Loading...