6

Original installation and operating instructions.

CONTENTS

Page

1. Symbols used in this document 6

2. Scope of these instructions 6

3. Product description 6

4. Nameplate 7

5. Type key 7

6. Operating conditions 8

7. Installation 8

7.1 Mechanical installation 8

7.2 Electrical installation 9

8. Control panel 9

9. Start-up 9

10. Operating modes 9

10.1 Manual operation 9

10.2 Automatic operation 9

10.3 Dry-running protection 9

10.4 Emergency operation 10

11. Functions 10

12. Settings 10

12.1 Setting the pressure switches 10

12.2 Setting the diaphragm tank pre-charge pressure 11

13. Maintenance 11

13.1 Pump 11

13.2 Settings 11

13.3 Frost protection 11

14. Fault finding chart 12

15. Related documentation 12

16. Disposal 12

1. Symbols used in this document

2. Scope of these instructions

These installation and operating instructions apply to Grundfos

Hydro Multi-S booster sets.

Hydro Multi-S is a range of factory-assembled booster sets, ready

for installation and operation.

3. Product description

The Grundfos Hydro Multi-S booster set is designed for pressure

boosting of clean water.

Examples:

• blocks of flats

• hotels

•schools.

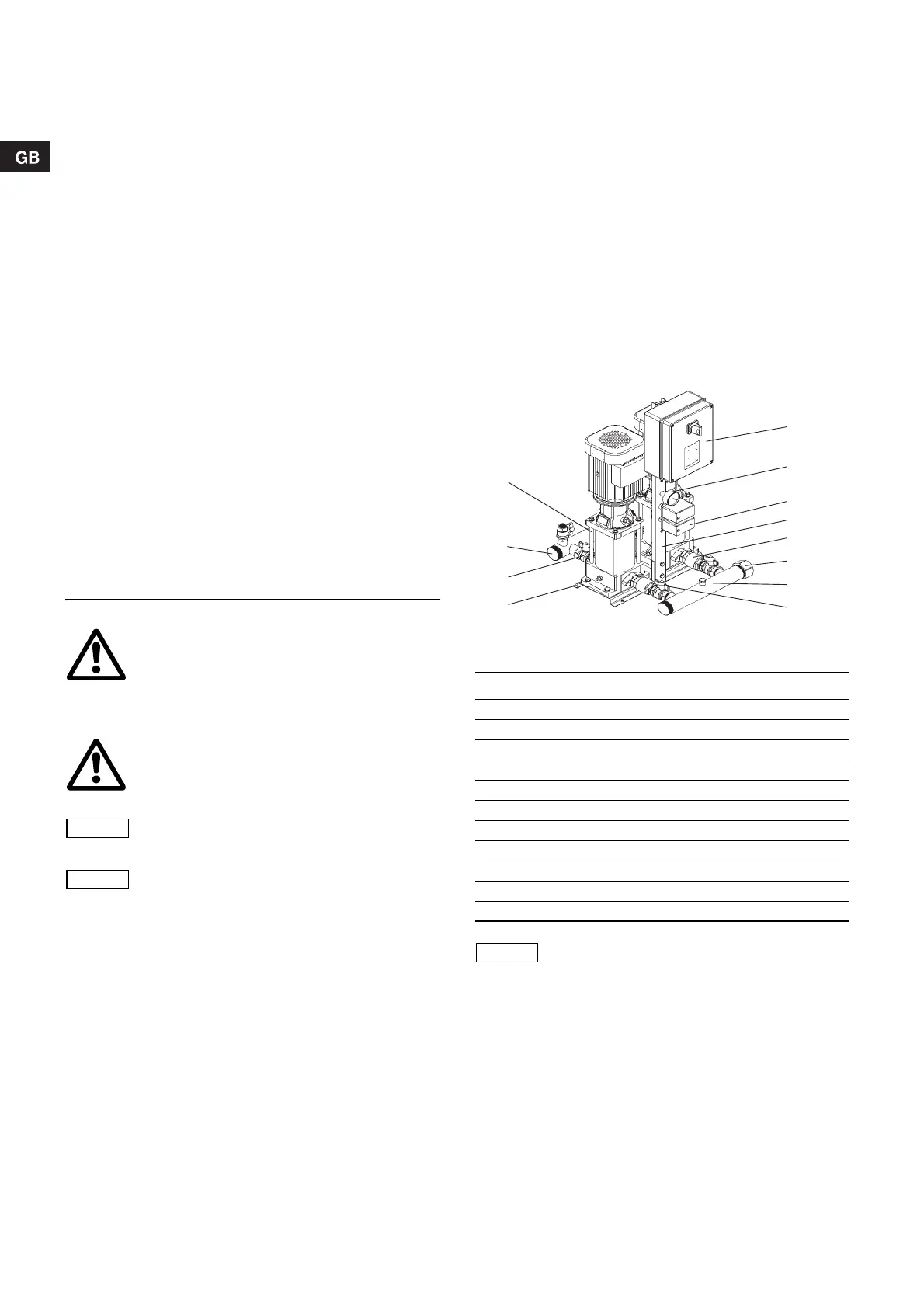

Hydro Multi-S consists of two or three identical Grundfos CH or

CR pumps connected in parallel and mounted on a common base

frame, suction and discharge manifolds, isolating valves, non-

return valves, pressure gauge, pressure switches and a control

cabinet. See fig. 1.

Fig. 1 Hydro Multi-S booster set

Warning

Prior to installation, read these installation and

operating instructions. Installation and operation

must comply with local regulations and accepted

codes of good practice.

Warning

If these safety instructions are not observed,

it may result in personal injury!

If these safety instructions are not observed,

it may result in malfunction or damage to the

equipment!

Notes or instructions that make the job easier

and ensure safe operation.

TM03 9724 4307

Pos. Components

1 Pumps (Grundfos CH or CR)

2 Discharge manifold

3 Isolating valves

4 Base frame

5 Control cabinet

6 Pressure gauge

7 Pressure switches

8 Stand

9 Non-return valves

10 Screw caps

11 Suction manifold

A diaphragm tank must always be installed on

the discharge side of the booster set.

Loading...

Loading...