Do you have a question about the Grundfos Hydro Multi-E and is the answer not in the manual?

Describes warning symbols and hazard statements used in the manual.

Explains symbols for instructions, warnings, and tips for easier work.

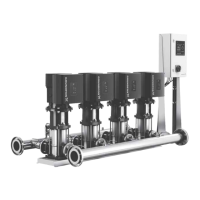

Describes the Hydro Multi-E system, its components, and applications.

Specifies the system's purpose and function for pressure boosting.

Details the information provided on the product's nameplate.

Explains the coding system used for product type designation.

Provides essential safety precautions for handling and lifting the system.

Guidance on selecting an optimal location for adequate cooling.

Detailed steps for the mechanical installation of the system.

Instructions on managing motor drain holes for moisture control.

Safety measures to prevent electric shock and indirect contact.

Details terminal connections for CRE, CRIE, and CRNE pump types.

Step-by-step guide for installing a CIM module.

Pre-startup cleaning instructions to ensure system hygiene.

Startup procedure for systems with positive inlet pressure.

Instructions for setting the desired pressure setpoint.

Overview of system settings and parameters.

Describes system operating modes like Stop, Normal, and Max.

Details on controlling the system to maintain constant pressure.

Details on the functions and configuration of analog inputs.

Methods for setting parameters via pump panel or external signal.

Instructions for setting system parameters using Grundfos GO.

Details on communication methods between Grundfos GO and the pump.

Methods to protect the system against dry running.

Maintenance guidelines for pumps, motors, and breaker cabinet.

Procedures for safely decommissioning the system.

Instructions for restarting the system after a standstill period.

Troubleshooting steps when the system fails to start.

Troubleshooting for systems that stop shortly after startup.

Troubleshooting steps when the system stops and won't restart.

Troubleshooting for issues related to unstable water supply.

Details on electrical supply voltage requirements and fuse sizes.

Specifications for leakage current according to standards.

Recommended torque values for terminal connections.

Environmental and operational limits for the system.

Safety precautions to follow before dismantling or disposing the system.

Guidance on environmentally sound disposal methods for the product.

| Product Name | Grundfos Hydro Multi-E |

|---|---|

| Category | Water Pump |

| Pump Type | Multi-stage centrifugal pump |

| Number of Pumps | 2-4 |

| Pressure Range | Up to 16 bar |

| Motor Power | Up to 22 kW per pump |

| Shaft Seal | Mechanical Seal |

| Control Type | Electronic |

| Pump Model | CRE |

| Power Supply | 3 x 380-480 V, 50/60 Hz |

| Max Head | 160 m |

| Approvals | CE |

| Communication | Modbus, BACnet |

| Housing Material | Stainless steel |

| Impeller Material | Composite |

| Connection Size | DN32 |

| Motor Type | Permanent magnet motor |