4. Installing the product

WARNING

Crushing

Death or serious personal injury

‐ Use professional installation tools when moving or

lifting the system or the components.

‐ Use safety equipment when mounting the base frame.

‐ Use the supplied wooden beams delivered to support

the system when mounting the vibration dampers.

‐ Installation must be carried out by trained personnel.

CAUTION

Overhead load

Minor or moderate personal injury

‐ Use appropriate lifting equipment when placing the

system.

CAUTION

Crushing of feet

Minor or moderate personal injury

‐ Use safety equipment when installing the pipes.

‐ Use safety equipment when installing the tank.

CAUTION

Sharp element

Minor or moderate personal injury

‐ Wear safety gloves.

4.1 Location

Observe the following to ensure adequate cooling of motor and

electronics:

• Position Hydro Multi-E in such a way that adequate cooling is

ensured. See section Ensuring motor cooling.

• The ambient temperature must not exceed 40 °C.

• Keep motor cooling fins and fan blades clean.

The system must have a 1-metre clearance in front and on the two

sides.

For outdoor installation, always place the system under a

roof to avoid exposing the system to direct sunlight.

Related information

4.2.1 Ensuring motor cooling

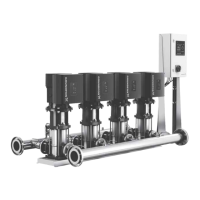

4.2 Mechanical installation

Arrows on the pump base show the direction of the flow of water

through the pump.

1. The pipes connected to the system must be of adequate size.

Fit expansion joints in the inlet and outlet pipes to avoid

resonance.

• Connect the pipes to the manifolds of the system.

The manifold comes with a screw cap fitted to one end. If this

end is to be used, remove the screw cap, apply sealing

compound to the other end of the manifold, and fit the screw.

Fit a blanking flange with gasket on flanged manifolds.

• Fasten all screws and bolts before starting the pump.

• If systems are installed in blocks of flats or the first consumer

on the line is close to the system, we recommend that you fit

expansion joints on the inlet and outlet pipes to prevent

vibration being transmitted through the pipes.

2. Position the system on a plane and solid surface, for example a

concrete floor or foundation. If the system is not fitted with

vibration dampers, it must be bolted to the floor or the

foundation.

3. Fasten the pipes to parts of the building to ensure that they

cannot move or be twisted.

TM007748

Installation example with expansion joints and pipe supports

Pos. Description

1 Expansion joint

2

Pipe support (and recommended location for isolating

valve)

The expansion joints and pipe supports shown in above figure are

not included in the standard system.

4.2.1 Ensuring motor cooling

Leave at least 50 mm between the end of the fan cover and a wall

or other fixed objects.

TM055236

Minimum distance (D) from the motor to a wall or other fixed

objects

4.3 Drain holes

When the motor is installed in moist surroundings or areas with high

humidity, the bottom drain hole must be open. If the humidity is

constantly high and above 85 %, open the drain holes in the drive-

end flange. The enclosure class of the motor will then be lower. This

helps prevent condensation in the motor as the motor becomes

self-venting, and it allows water and humid air to escape.

The motor has a plugged drain hole on the drive side. You can turn

the flange 90° to both sides or 180°.

TM029037

Drain holes

9

English (GB)

Loading...

Loading...