17. Digital input

Hydro Multi-E has a digital input for external faults. The input has

been factory-set to external fault and will be active in closed

condition.

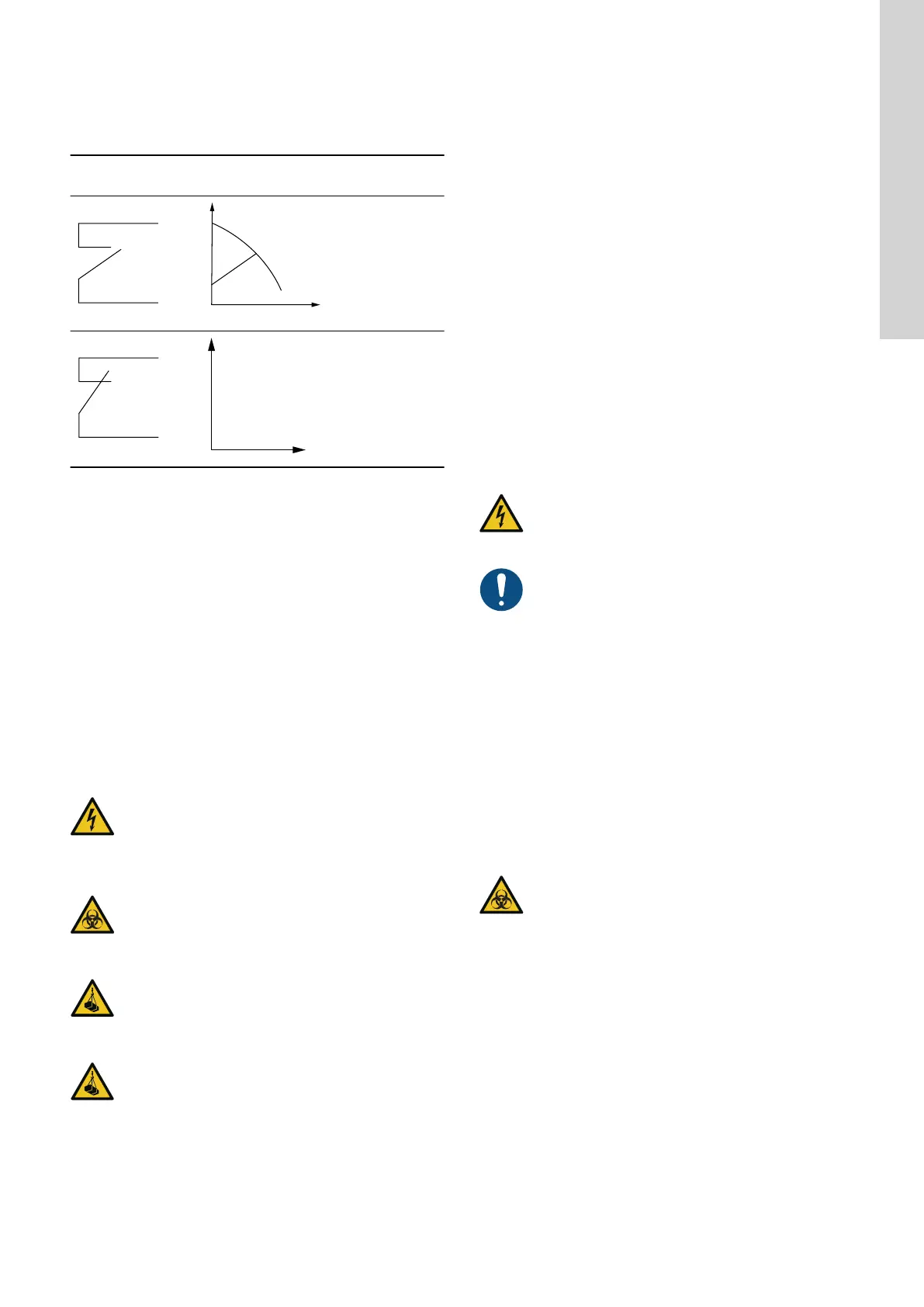

Functional diagram: input for digital function

Digital function

(terminals 1 and 9)

Normal duty

External fault

If the digital input is active for more than 10 seconds (s), Hydro

Multi-E will stop because of an external fault.

The digital input is used for the dry-running protection.

18. Data communication

It is possible to connect the system to an external network. The

connection can be made via a GENIbus-based network or a

network based on another fieldbus protocol.

The system can communicate via CIM modules. This enables the

system to communicate with different types of network solutions.

A CIM module is an add-on communication interface module. The

CIM module enables data transmission between the pump and an

external system, for example a BMS or SCADA system.

For further information on CIM modules, see Grundfos Product

Center at www.grundfos.com or contact Grundfos.

19. Servicing the product

DANGER

Electric shock

Death or serious personal injury

‐ Before you maintain the system, make sure that the

power supply is disconnected and cannot be

accidentally switched on.

WARNING

Contaminated drinking water

Death or serious personal injury

‐ Flush the system after a standstill period in

compliance with local legislation.

WARNING

Overhead load

Death or serious personal injury

‐ Use hard hat.

CAUTION

Overhead load

Minor or moderate personal injury

‐ Use appropriate tools and lifting equipment for

maintenance.

19.1 Maintaining the product

19.1.1 Pumps

Pump bearings and shaft seals are maintenance-free.

If pumps are to be drained for a long period of inactivity, remove

one of the coupling guards to inject a few drops of silicone oil on the

shaft between the pump head and the coupling. This will prevent

the shaft seal faces from sticking.

19.1.2 Motors

Keep motor cooling fins and fan blades clean to ensure sufficient

cooling of the motor and electronics.

Motors above 7.5 kW must be lubricated according to the

recommended intervals and type of bearing grease stated on the

motor.

Motors above 10.0 Hp (7.5 kW) must be lubricated according to the

recommended intervals and type of bearing grease stated on the

motor.

19.1.3 Breaker cabinet

The breaker cabinet is maintenance-free. Keep it clean and dry.

19.1.4 Service kits

See Grundfos Product Center at www.grundfos.com for service

manuals.

19.2 Taking the product out of operation

DANGER

Electric shock

Death or serious personal injury

‐ Make sure that the power supply is disconnected and

cannot be accidentally switched on.

Drain the product if you are not going to use it for a long

time.

1. Switch off the main switch to take the system out of operation.

2. Switch off the corresponding motor protective circuit breaker,

automatic circuit breaker or fuse to take the individual pump out

of operation.

19.2.1

Frost protection

If pumps are not used during periods of frost, they must be drained

to avoid damage.

Drain the pump by loosening the vent screw in the pump head and

removing the drain plug from the base.

Do not tighten the vent screw or refit the drain plug until the system

is to be used again.

19.3 Startup the product after standstill

WARNING

Contaminated drinking water

Death or serious personal injury

‐ Flush the system after a standstill period in

compliance with local legislation.

See section Startup for further instructions.

Related information

7. Startup

41

English (GB)

Loading...

Loading...