10.4 Pipe-filling function

The function is typically used in pressure-boosting applications and

ensures a smooth startup of systems with for instance empty pipes.

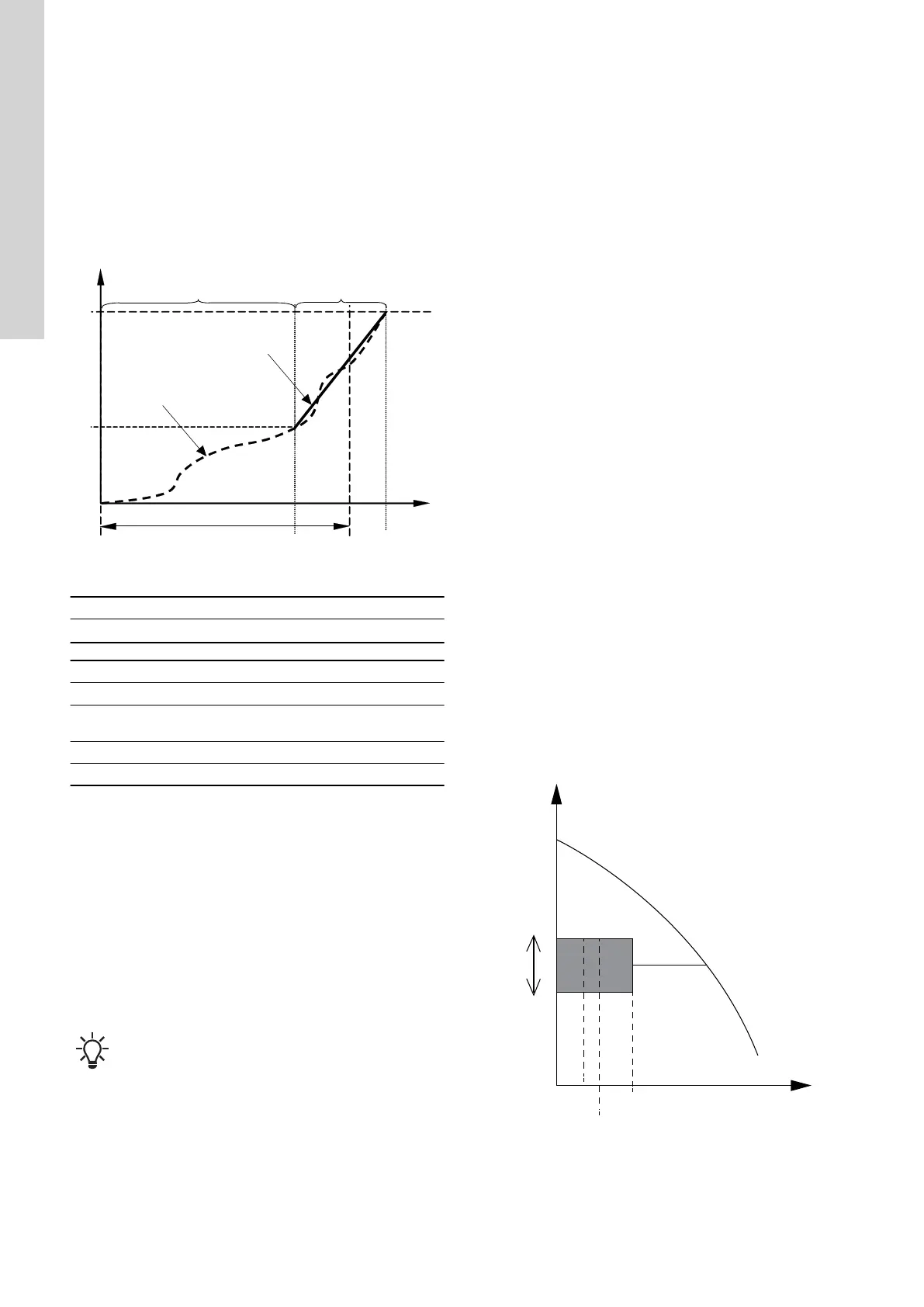

Startup takes place in two phases:

• Filling phase (1): The pipes are slowly filled with water. When

the pressure sensor of the system detects that the pipes have

been filled, Phase 2 begins.

• Pressure build-up phase (2): The system pressure is

increased until the setpoint (SP) is reached. The pressure

buildup takes place over a ramp time. If SP is not reached within

a given time, a warning or an alarm can be given, and the

pumps can be stopped at the same time.

TM078698

Filling and pressure build-up phases

P: Pressure T: Time [second]

P

f

: Filling pressure T

f

: Filling time

Pos. Description

1 Filling phase: constant-curve operation

2

Pressure build-up phase: constant-pressure

operation

A Actual value

B Setpoint ramp-up

Setting range

• Filling speed. Fixed speed of the pump during the filling phase.

• Filling pressure. The pressure that the pump must reach

before the maximum filling time.

• Max. filling time. The time in which the pump must reach the

filling pressure.

• Max. time reaction. Reaction of the pump if the maximum filling

time is exceeded:

- warning

- alarm (pump stops).

• Pressure build-up time. Ramp time from when the filling

pressure is reached until the setpoint must be reached.

When you activate this function, the function always starts

when the pump has been in operating mode Stop and is

changed to Normal.

Factory settings

See section Factory settings.

Related information

21.6 Factory settings

10.5

Stop function

You can set the Low-flow stop function to these values:

• Not active

• Energy-optimal mode

• High-comfort mode

• User-defined mode (Customised operating mode).

When the Low-flow stop function is active, the flow is monitored.

If the flow becomes lower than the set minimum flow (Q

min

), the

pump changes from continuous operation at constant pressure to

start-stop operation and stops if the flow reaches zero.

The advantages of enabling the Low-flow stop function are the

following:

• no unnecessary heating of the pumped liquid

• reduced wear of the shaft seals

• reduced noise from operation.

The disadvantages of enabling the Low-flow stop function may be

the following:

• The delivered pressure is not completely constant as it

fluctuates between the start and stop pressures.

• The frequent starts/stops of the pump may in some applications

cause acoustic noise.

The impact of the above disadvantages very much depends on the

setting selected for the stop function.

The High-comfort mode setting minimises pressure fluctuations

and acoustic noise.

Select Energy-optimal mode if the main priority is to reduce the

energy consumption as much as possible.

Possible settings of the stop function:

• Energy-optimal mode: The pump automatically adjusts the

parameters for the stop function so that the energy consumption

during the start-stop operation period is minimised. In this case,

the stop function uses the factory-set values of the minimum

flow (Q

min1

) and other internal parameters.

• High-comfort mode: The pump automatically adjusts the

parameters for the stop function so that the disturbances during

the start-stop operation period are minimised. In this case, the

stop function uses the factory-set values of the minimum flow

(Q

min2

) and other internal parameters.

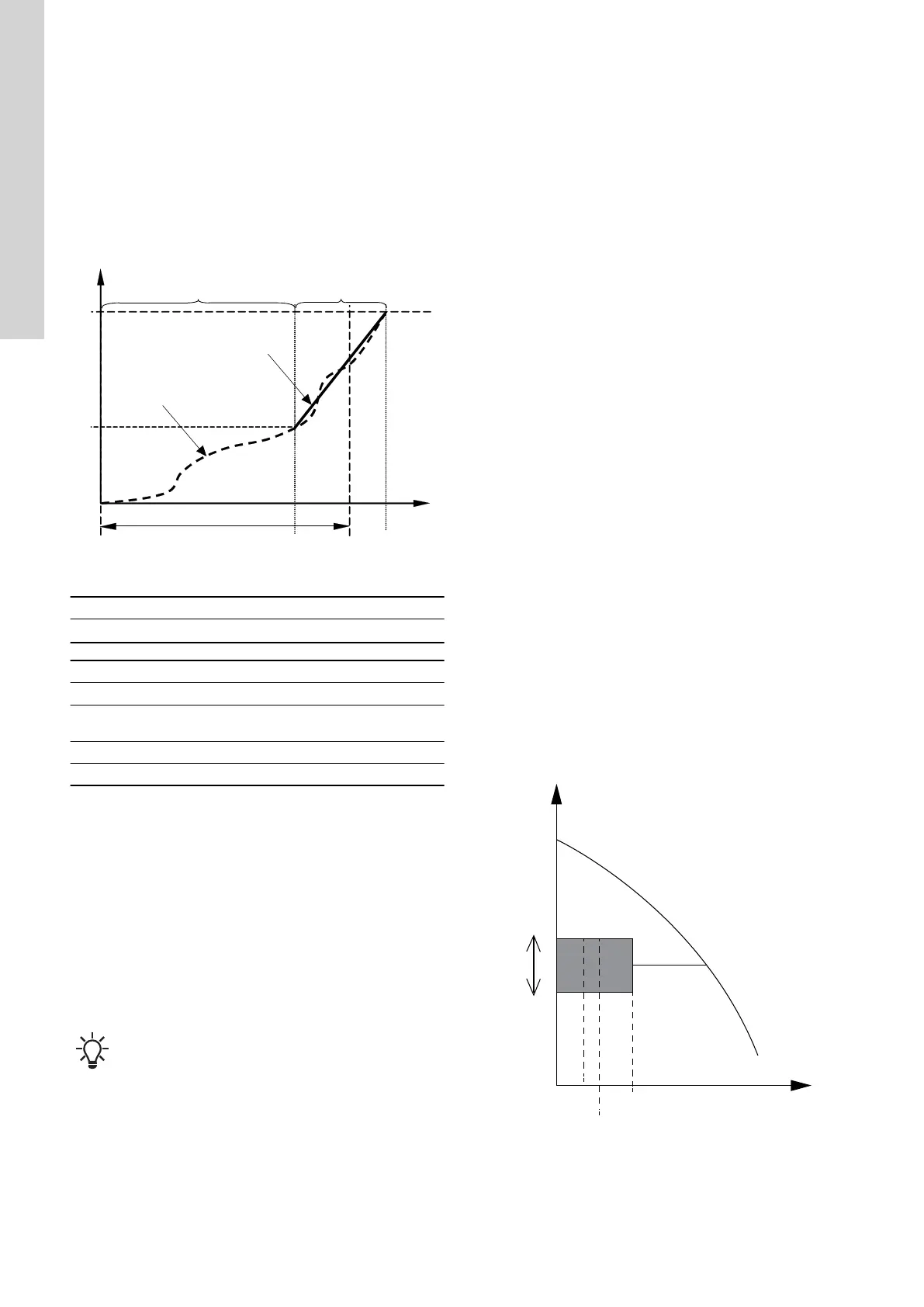

• User-defined mode (Customised operating mode): The

pump uses the parameters set for ΔH and minimum flow (Q

min3)

respectively for the stop function.

TM064267

Difference between start and stop pressures (ΔH) and minimum

flow rate

22

English (GB)

Loading...

Loading...