13. Protective functions

It is important that any protective function, for example dry-running

protection or external start/stop that is detected via a digital input, is

connected to and configured on all the pumps with an outlet-

pressure sensor.

If an additional sensor is used, for example the limit-exceeded

function or setpoint influence, this sensor must also be connected to

all pumps with an outlet-pressure sensor. Alternatively, an additional

sensor per pump with an outlet-pressure sensor can be installed.

13.1 Dry-running protection

Hydro Multi-E must be protected against dry running.

Types of dry-running protection:

• a pressure switch or an inlet pressure sensor is factory-fitted to

the inlet manifold. See sections Pressure switch and Inlet

pressure sensor.

• a level switch fitted in a water tank (optional). See section Level

switch.

Related information

13.1.3 Inlet pressure sensor

13.1.1 Pressure switch

13.1.2 Level switch

13.1.1

Pressure switch

The Hydro Multi-E can be fitted with an adjustable pressure switch

as dry-running protection. The pressure switch is fitted to the inlet

manifold.

If the inlet pressure is below the lower switching point, the

system cannot start.

If the pressure switch has stopped the system during

operation due to the inlet pressure being too low, the inlet

pressure must increase to a pressure that is higher than

the setting of the upper switching point before the system

can restart.

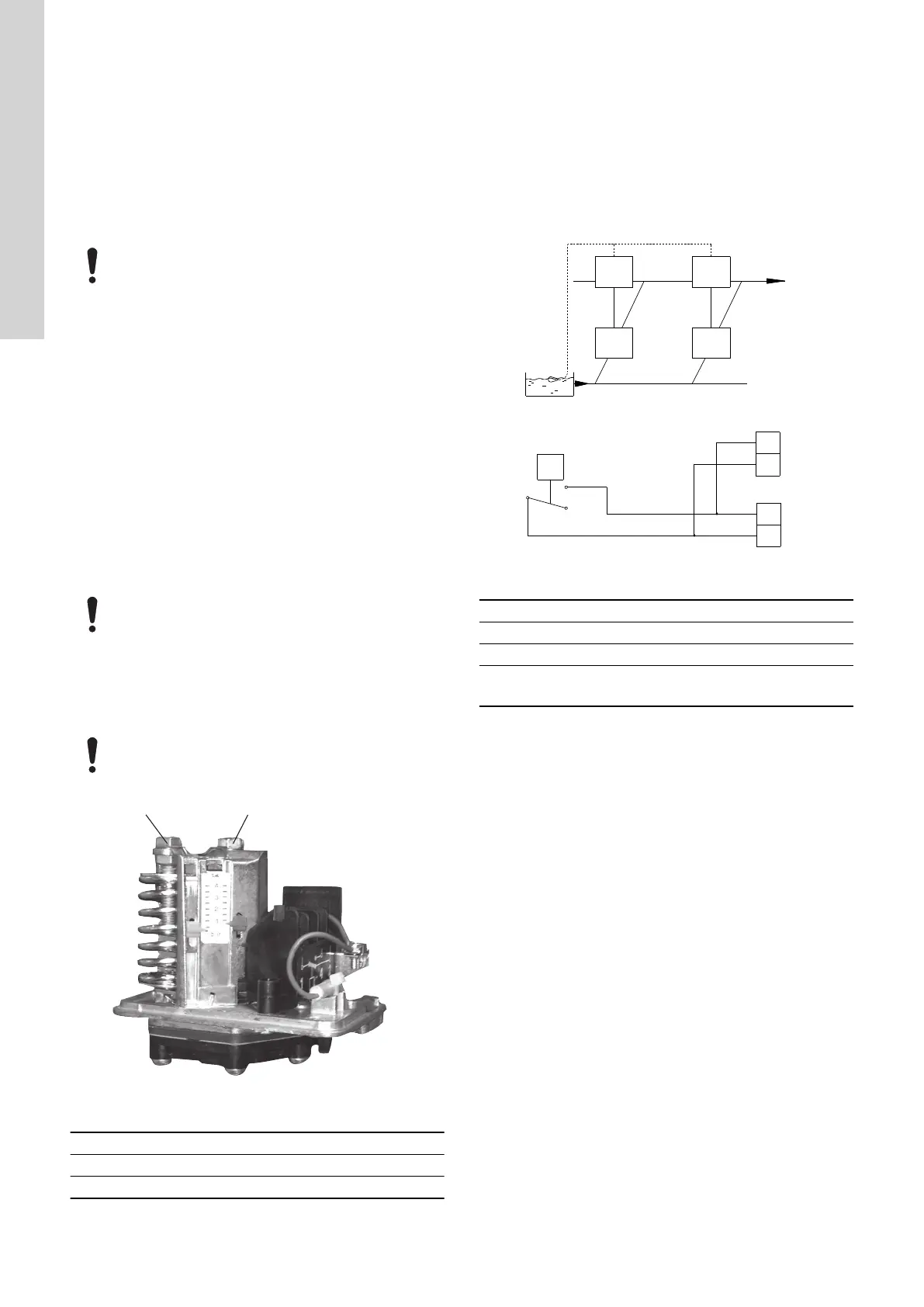

If necessary, adjust the lower switching point by turning screw A

and adjust the upper switching point to a value higher than the

lower switching point by turning screw B. See figure below.

Do not set the lower switching point to a value below the

minimum inlet pressure. See section Minimum inlet

pressure.

TM058436

Adjustment of switching points

Pos. Description

A Low pressure SP

B High pressure SP

Related information

21.4.7 Minimum inlet pressure

13.1.2

Level switch

If there is no inlet pressure, the system can be optionally fitted with

a level switch, either from factory or after delivery. The level switch

can for instance monitor the water level in a tank connected to the

inlet manifold and must be connected to terminal 3 and 10 in all

pumps. See Advanced functional module (FM 300) in section Inlet

pressure sensor.

Furthermore, the digital input must be configured with Grundfos GO

to detect dry running.

The system starts up automatically if it has been stopped due to dry

running. It can be changed to manually restart with Grundfos GO.

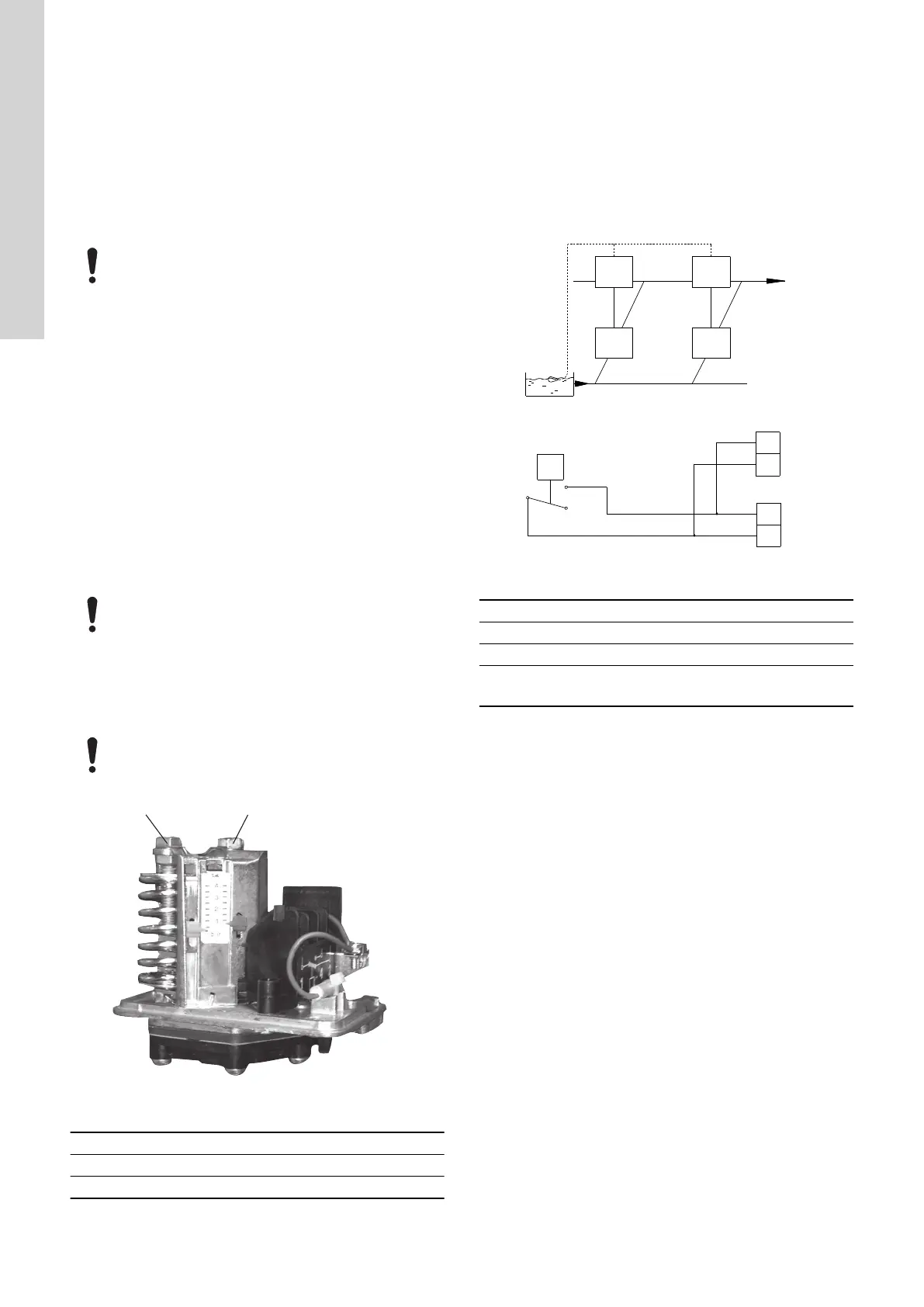

TM065328

Level switch connected to each pump

Pos. Description

A Pump 1

B Pump 2

C

3: GND (frame)

10: Digital input

Related information

13.1.3 Inlet pressure sensor

36

English (GB)

Loading...

Loading...