4.4 Electrical installation

Carry out the electrical connection according to local regulations.

Check that the supply voltage and frequency correspond to the

values stated on the nameplate.

DANGER

Electric shock

Death or serious personal injury

‐ Switch off the power supply and make sure that the

power supply cannot be accidentally switched on.

‐ Make sure that the wires to be connected to the

connection groups are separated from each other by

reinforced insulation in their entire lengths.

WARNING

Electric shock

Death or serious personal injury

‐ Installation must be carried out by qualified personnel,

and according to local regulations.

If the power supply cable is damaged, it must be replaced by the

manufacturer, the manufacturer's service partner or a similarly

qualified person.

The user or the installer is responsible for the installation of correct

earthing and protection according to local regulations. All operations

must be carried out by a qualified electrician.

The system must be stationary and installed

permanently. Furthermore, connect the system permanently to the

power supply.

Carry out the earth connection as duplicate conductors.

If the system cannot be installed with the supply disconnecting

device located minimum 0.6 m above service level according to EN

60204-1 paragraph 5.3.4, install the system with an external "supply

disconnecting device" made according to EN 60204-1, paragraph

5.3.2. The system must be provided with a means permitting it to be

locked in OFF (isolated) position.

4.4.1

Protection against electric shock, indirect contact

DANGER

Electric shock

Death or serious personal injury

‐ Connect the motor to protective earth and protect

against indirect contact according to local regulations.

Protective-earth conductors must always have a green, or green/

yellow (PE) colour marking.

Protection against mains voltage transients

The motor is protected against mains voltage transients in

accordance with EN 61800-3.

Motor protection

The motor requires no external motor protection. The motor

incorporates thermal protection against slow overloading and

blocking.

4.4.2

Insulation resistance

Do not measure the insulation resistance of motor

windings or an installation incorporating motors with

integrated frequency converters using high-voltage

megging equipment as this may damage the built-in

electronics.

4.5 Mains supply

Check that the supply voltage and frequency correspond to the

values stated on the nameplate.

Use dedicated IT network motors if the system is supplied

through an IT network. Contact Grundfos.

The wires in the breaker cabinet must be as short as possible.

Excepted from this is the separated earth conductor which must be

so long that it is the last one to be disconnected in case the cable is

inadvertently pulled out of the cable entry.

For maximum backup fuse, see section Supply voltage.

A

N

N

B

PE

L3

L3

L2

L2

L1

L1

ELCB

(GFCI)

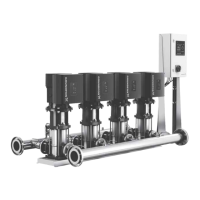

TM024547

Example of a mains-connected Hydro Multi-E with backup fuses

and additional protection (applies only for systems with single-

phase motors)

Pos. Description

A Installation in building

B Breaker cabinet

For maximum backup fuse, see section Supply voltage.

A

ELCB

(GFCI)

PE

L3

L2

L1

L3

L2

L1

B

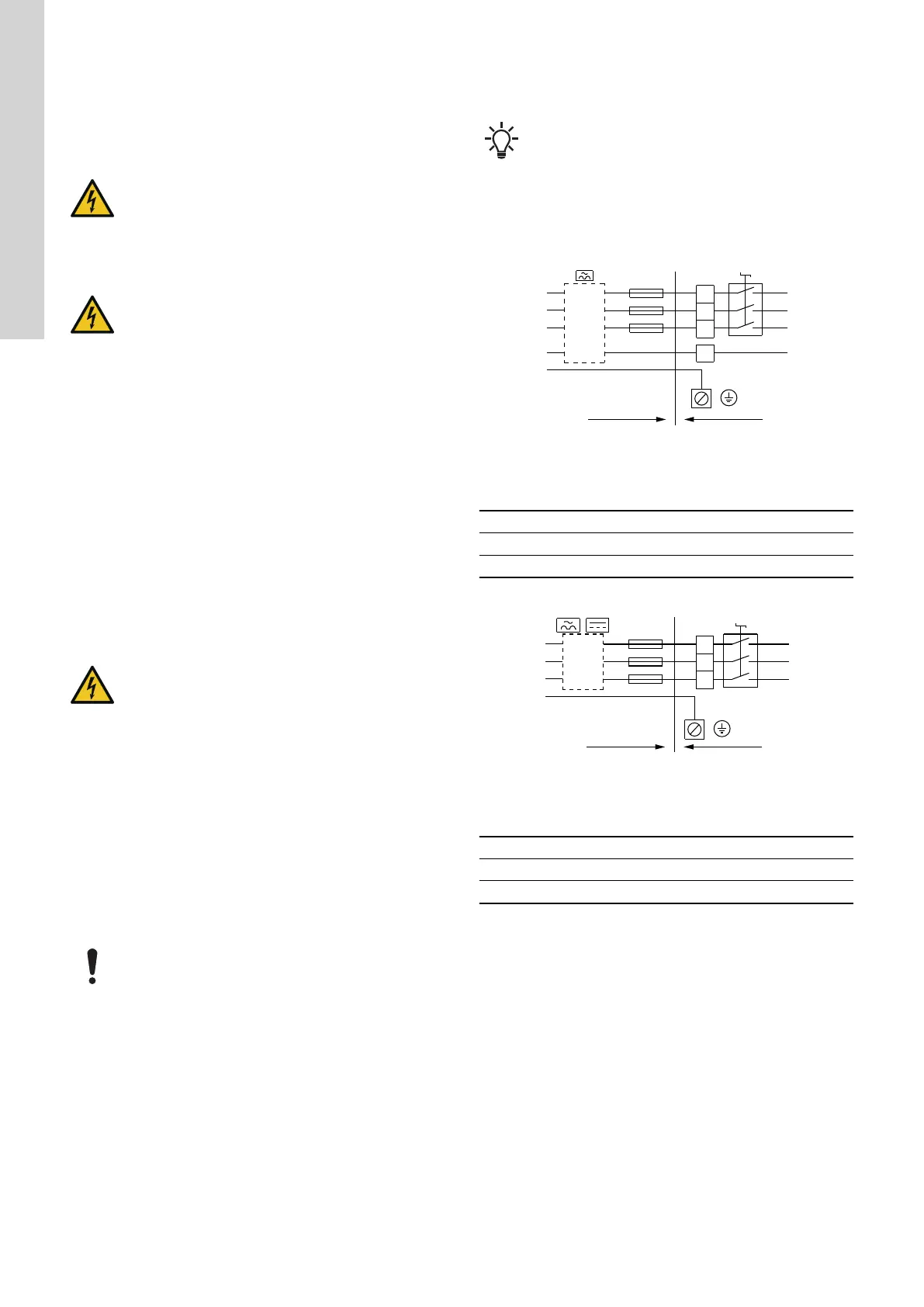

TM024546

Example of a mains-connected Hydro Multi-E with backup fuses

and additional protection (applies only for systems with three-

phase motors)

Pos. Description

A Installation in building

B Breaker cabinet

Related information

21.1 Supply voltage

10

English (GB)

Loading...

Loading...