4.3 Priming

If not primed properly, the pump will not

deliver liquid.

Closed systems or open systems where the liquid

level is above the pump inlet (flooded systems)

Fill the inlet pipe and pump with liquid and vent them

before the pump is started. Proceed as follows:

1. Close the outlet isolating or throttle valve.

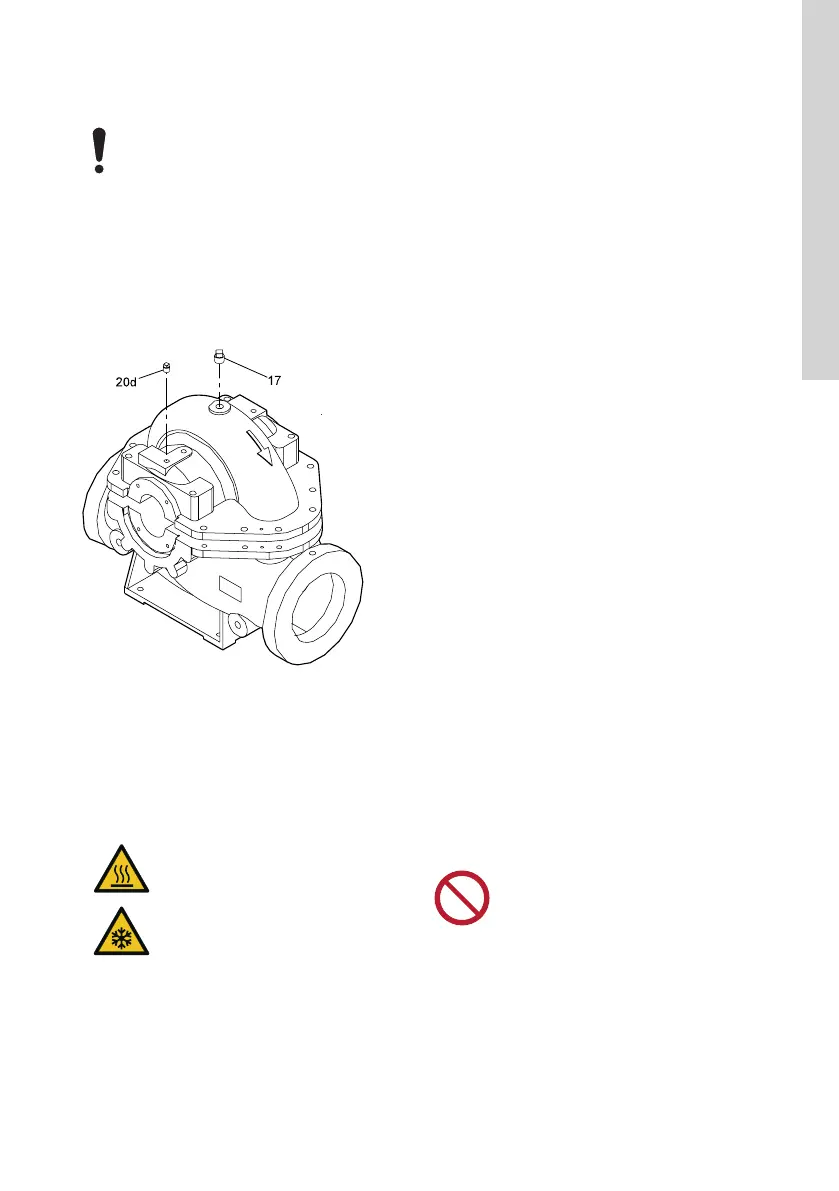

2. Loosen the vent screw (17) and the plug for shaft

seal flushing (20d).

TM042592

Position of the vent valve and plug for shaft seal

flushing

WARNING

Hot or cold surface

Death or serious personal injury

‐ Pay attention to the direction of the

vent hole, and ensure that the

escaping water does not cause

injury to persons or damage to the

motor or other components.

‐ In hot-water installations, pay

special attention to the risk of injury

caused by scalding hot water and

hot surfaces.

‐ In cold-liquid installations, pay

special attention to the risk of injury

caused by cold liquids and cold

surfaces.

3. Slowly open the isolating valve in the inlet pipe

until a steady flow of liquid runs out of the vent

hole.

4. Rotate the shaft by hand, if possible, while priming

and venting to free entrapped air from the impeller

channels.

5. Tighten the vent screw and completely open the

isolating or throttle valve(s).

Open systems where the liquid level is below the

pump inlet (suction lift systems)

Fill the inlet pipe and pump with liquid and vent them

before the pump is started. Proceed as follows:

Suction lift system with foot valve

1. Close the outlet isolating or throttle valve and

open the isolating valve in the inlet pipe.

2. Remove the vent screw and connect a priming

device to a drain hole.

3. Fill the inlet pipe and casing with liquid at a

pressure of 1 to 2 bar from an external source

until the inlet pipe and pump are completely filled

with liquid.

4. Rotate the shaft by hand while priming and

venting to free entrapped air from the impeller

channels.

5. Refit the vent screw and tighten it securely.

6. You can fill the inlet pipe with liquid and vent it

before you connect the pipe to the pump. You can

also install a priming device before the pump.

Suction lift system without foot valve

1. Connect an external vacuum pump to the vent

hole on the top of the pump casing.

2. Close the outlet isolating or throttle valve and

open the isolating valve in the inlet pipe.

3. Open the valves between the pump and vacuum

pump.

4. Start the external vacuum pump.

5. Pump until the inlet pipe and the pump are

completely filled with liquid.

6. Rotate the shaft by hand while priming and

venting to free entrapped air from the impeller

channels.

7. When the liquid runs out of the vacuum pump,

stop the external vacuum pump and close the

valves between the pump and vacuum pump.

Never let the pump run dry. The pump is

not self-priming.

Dry-running will cause serious damage to

the stuffing boxes, shaft seals, wear rings

and shaft sleeves.

4.3.1 Opening of valves

1. Open the valves for the flushing liquid to the

stuffing boxes.

2. Completely open the isolating valve on the inlet

side of the pump and leave the outlet isolating or

throttle valve partly open.

21

English (GB)

Loading...

Loading...