28.04.2003

GB

14 / 24

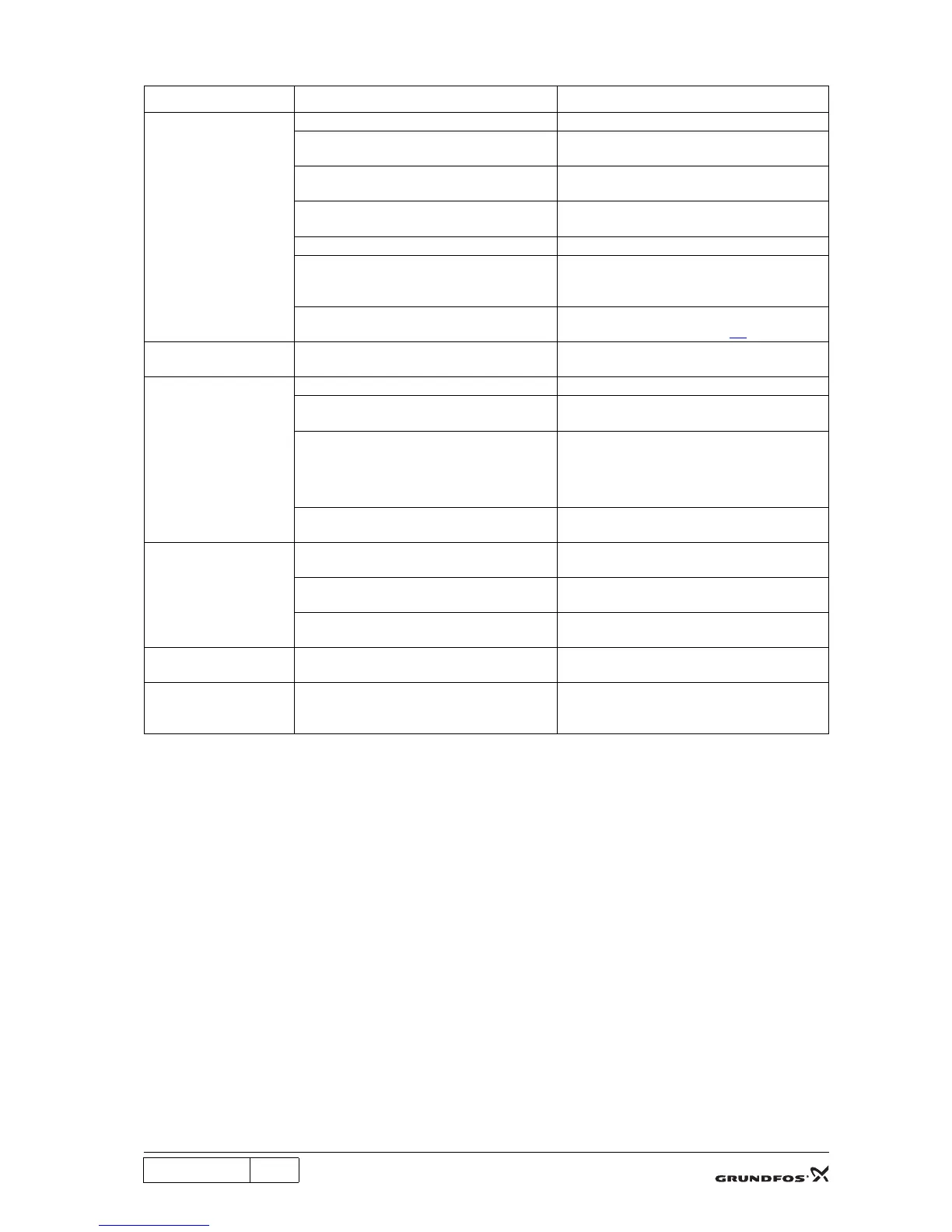

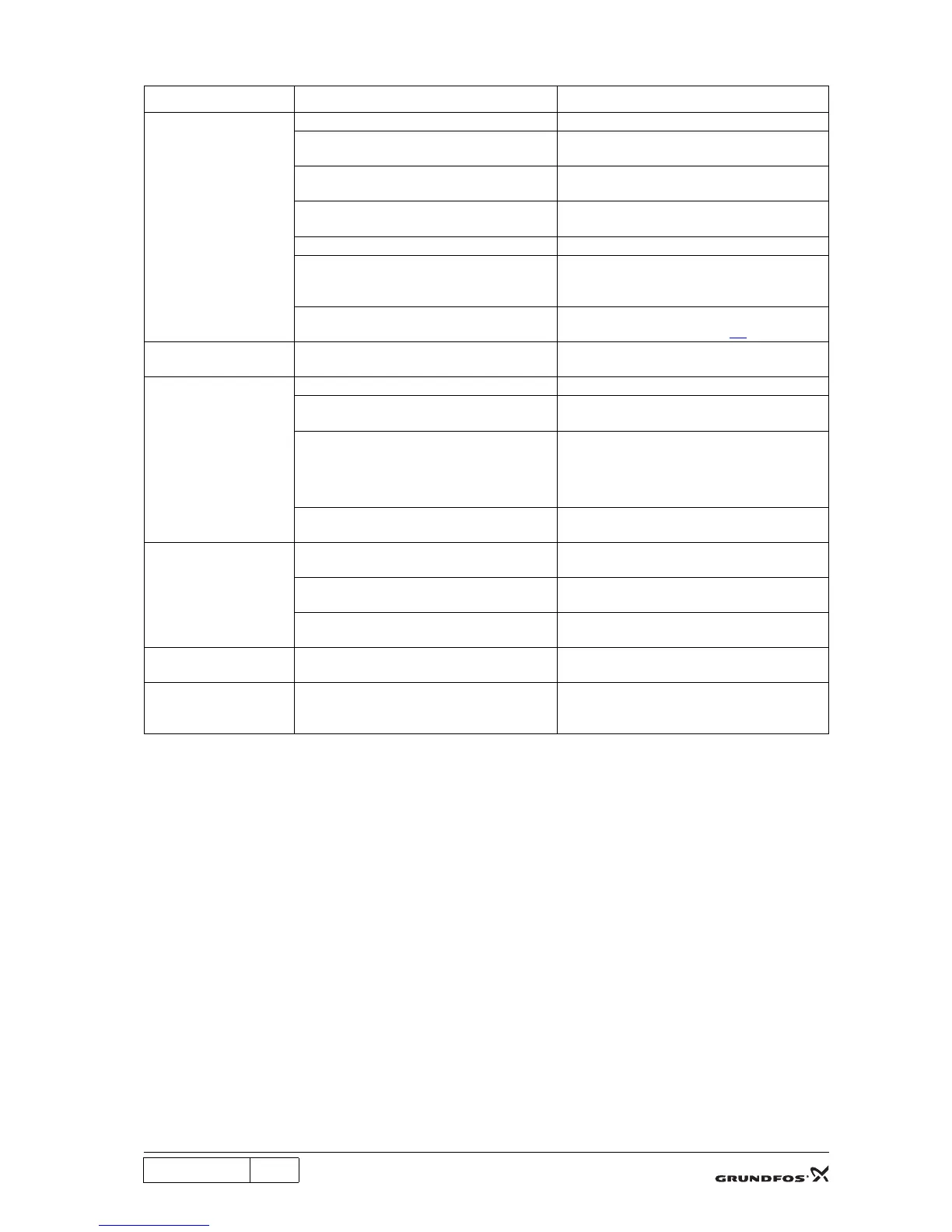

4.9 Fault finding

If the pump does not start when the fault has been corrected, contact your pump supplier or GRUNDFOS for

further information.

Fault Cause Remedy

1. The pump does not

start.

a) Insufficient water. Check the water supply/suction pipe.

b) Overheating due to excessive liquid

temperature (above +35°C).

Supply cold liquid to the pump.

c) Overheating due to seized-up/choked-

up pump.

Contact your pump supplier.

d) Too low or too high supply voltage. Check the supply voltage and correct the

fault, if possible.

e) No electricity supply. Connect the electricity supply.

f) No water consumption. Turn on a tap. Check that the height be-

tween the top point of the discharge pipe

and the pump does not exceed 15 metres.

g) The pump is in alarm condition. Reset the pump by means of the on/off but-

ton. See the table in section 4.7

.

2. The pump does not

stop.

a) The existing pipework is leaking or

defective.

Repair the pipework.

3. The pump cuts out

during operation.

a) Dry running. Check the water supply/suction pipe.

b) Overheating due to excessive liquid

temperature (above +35°C).

Supply cold liquid to the pump.

c) Overheating caused by:

• high ambient temperature (> +45°C),

• overloaded motor or

• seized-up motor/pump.

Contact your pump supplier.

d) Too low supply voltage. Check the supply voltage and correct the

fault, if possible.

4. The pump starts and

stops too frequently.

a) Leakage in suction pipe or air in the

water.

Check the water supply/suction pipe/O-

rings on the inlet part.

b) Too low or too high pressure in pressure

tank pos. 42.

Check pressure in pressure tank. The pres-

sure must be 1.5 to 1.7 bar.

c) Seized-up or missing non-return valve. Clean the valve or fit a new non-return

valve.

5. The pump gives elec-

tric shocks.

a) Defective earth connection. Connect the earth connection to the pump

in accordance with local regulations.

6. The pumps starts

when no water is con-

sumed.

a) Defective non-return valve or the exist-

ing pipework is leaking or defective.

Clean the valve or fit a new non-return

valve.

Loading...

Loading...