English (GB)

8

3.4 Tools

• Thread tape

•Glue

Not delivered with the product:

• Drilling machine

• Drilling bits: Ø6, Ø16, Ø25

• Cup saw: Ø40, Ø100

• Deburring tool for polyethylene

3.5 Installation overview

Depending on your product type, you must go

through different steps in order to install and setup

your system. The steps below are necessary steps in

order to start your system. You may need to go

through extra steps if you have additional

accessories.

Unolift/Duolift with pumps with float switches

1. Fix tank to the floor

2. Drill holes for inlet pipes

3. Connect inlets to tank

4. Fit venting port and cable glands

5. Adjust length of float switch cable to set start

levels

6. Install pumps inside tank

7. Fit inner connecting pipe

8. Fit venting pipe

9. Fit discharge pipes

Unolift/Duolift with controller and level sensor

tube

1. Fix tank to the floor

2. Drill holes for inlet pipes

3. Connect inlets to tank

4. Fit venting port and cable glands

5. Install pumps inside tank

6. Install sensor tube inside tank

7. Fit inner connecting pipes

8. Fit venting pipe

9. Fit discharge pipes

3.6 Positioning the product

Position the tank so that all components are easily

accessible during operation and maintenance.

3.7 Installing the tank

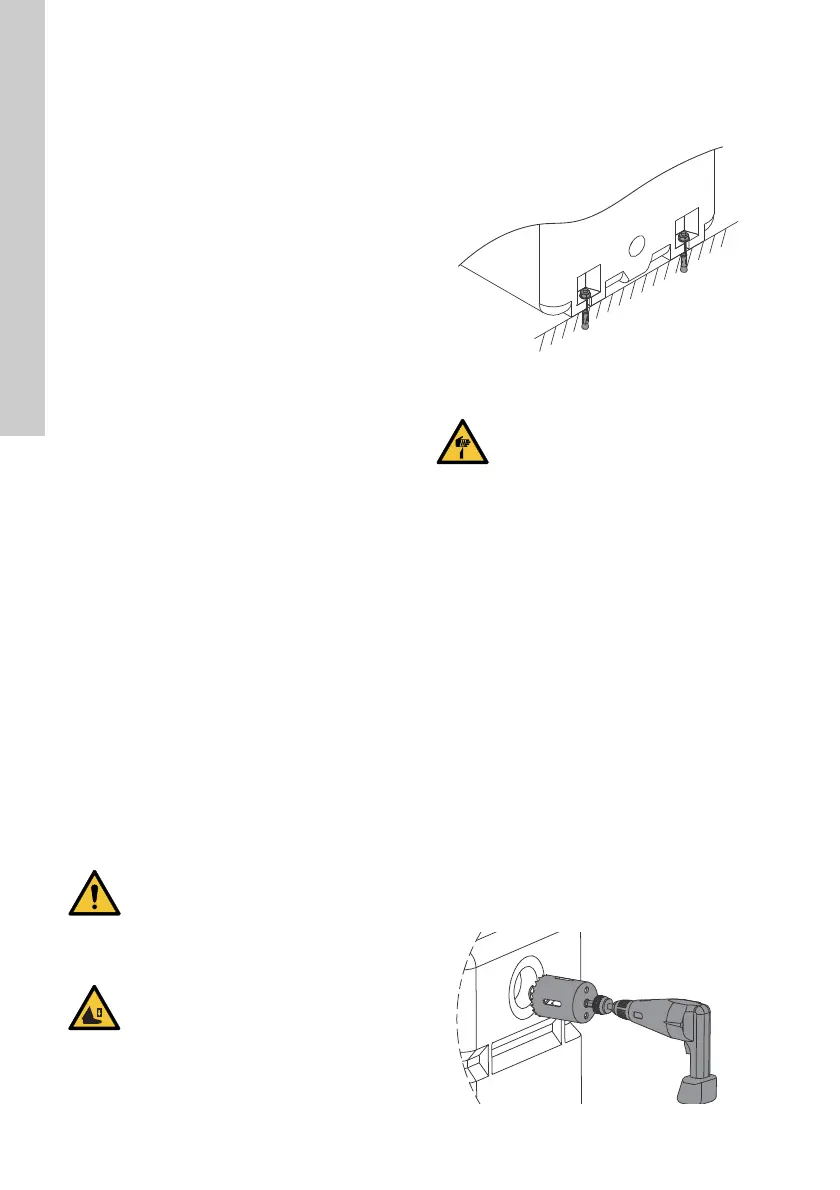

Fix the tank to the floor to prevent uplift and twist.

Use the mounting brackets to fix the tank with

screws.

3.8 Drilling holes in the tank

Depending on the size, the the tank has three to four

pre-moulded holes ∅ 100 for the inlet pipes. The

tank also has a pre-mouled hole ∅ 40 for the

diaphragm pump. See section 5.1 Product overview.

These holes must be cut opened in order to be used.

Holes for discharge pipes, venting pipe and minimum

required cable glands are already opened.

The minimum required cable glands depend on the

model:

• Unolift, APB, CC, KP: one hole opened for pump

cable

• Unolift SEG: two holes opened for pump cable

and sensor hose

• All Duolifts: three holes opened for pump cables

(2) and sensor hose (1)

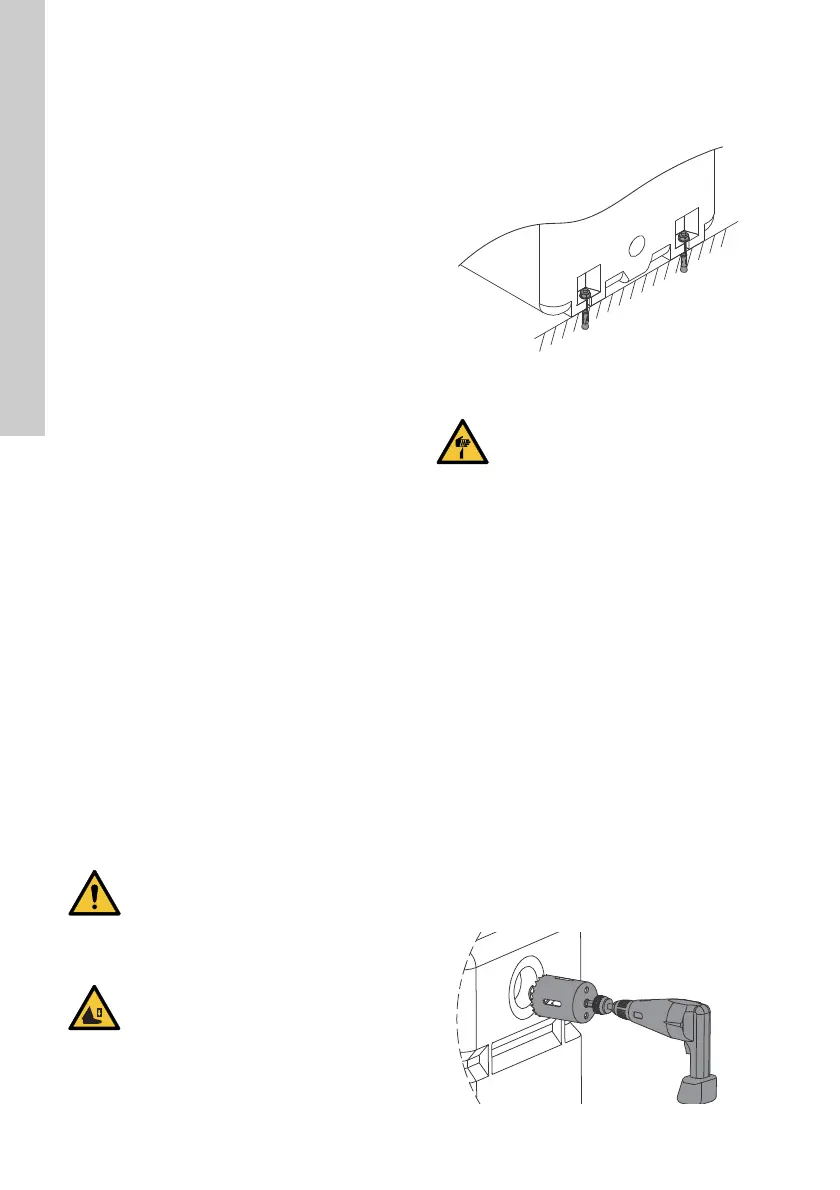

3.8.1 Drilling holes for pipes

1. Determine which inlets you want to use.

See “Choice of tank inlets” on page 6.

2. Drill holes with a cup saw.

The diameter of the cup saw must be the same

as the diameter of the pipe.

Inlet: Ø100

Outlet, pipe for diaphragm pump: Ø40

3. Deburr the holes.

Fig. 3 Drilling holes for pipes

CAUTION

Back injury

• Minor or moderate personal injury

• Get assistance from another person or

use lifting equipment to carry the

product.

CAUTION

Crushing of feet

• Minor or moderate personal injury

• Wear safety shoes when moving the

product.

TM065780 0116

CAUTION

Sharp element

• Minor or moderate personal injury

• Wear protective gloves.

TM065851 0216

Loading...

Loading...