Option Description

Sensor Ports Tells the sensors connected to the sampler do a measurement and supply

advanced information used to identify if the sensor operation is correct. Shows the

measurements and information applicable to the measurements. Shows the type

and firmware version for each sensor.

AUX (or

IO9000 module)

Shows the configuration settings for the AUX I/O port, the flow input signal

(0/4–20 mA) and the flow value. In addition, information used by technical support

shows (ADC counts, Cal gains and Cal offsets).

Note: If the optional IO9000 module is connected to the AUX I/O port, the

configuration and status of the analog inputs, analog output, digital outputs and

relays show after the IO9000 module is configured.

Distributor Moves the distributor arm to all the bottle positions regardless of the number of

bottles that are selected in the sampling program.

Note: To do a diagnostic test for the distributor arm, the sampling program must be

configured for multiple bottles.

Keypad Shows each key that is pushed on the keypad.

Display Sets each pixel of the display to on and off in different patterns.

Memory Shows the percent of the controller memory used.

Calibrate the liquid detector

If the samples composition is very different than tap water, calibrate the liquid detector with the

guidance of technical support. For example, turbidity more than 1000 NTU or solids more than 2%.

1. Put the intake tubing into the sample water.

2. Push MENU.

3. Select Hardware Setup>Liquid Detect>Status. Make sure that the liquid detector is enabled.

4. Select Calibrate>Next. The pump operates in reverse to purge the intake tube. The pump then

operates in the forward direction.

5. When the sample goes through the liquid detector and bubbles are not present, push STOP. The

intake tube is automatically purged. The liquid detector calibration is complete. Make sure that the

display shows no errors occurred.

6. Push Finish to exit or push Retry to do the calibration again.

Appendix

Manning roughness coefficients

Refer to Table 12 and Table 13 for the Manning roughness coefficients.

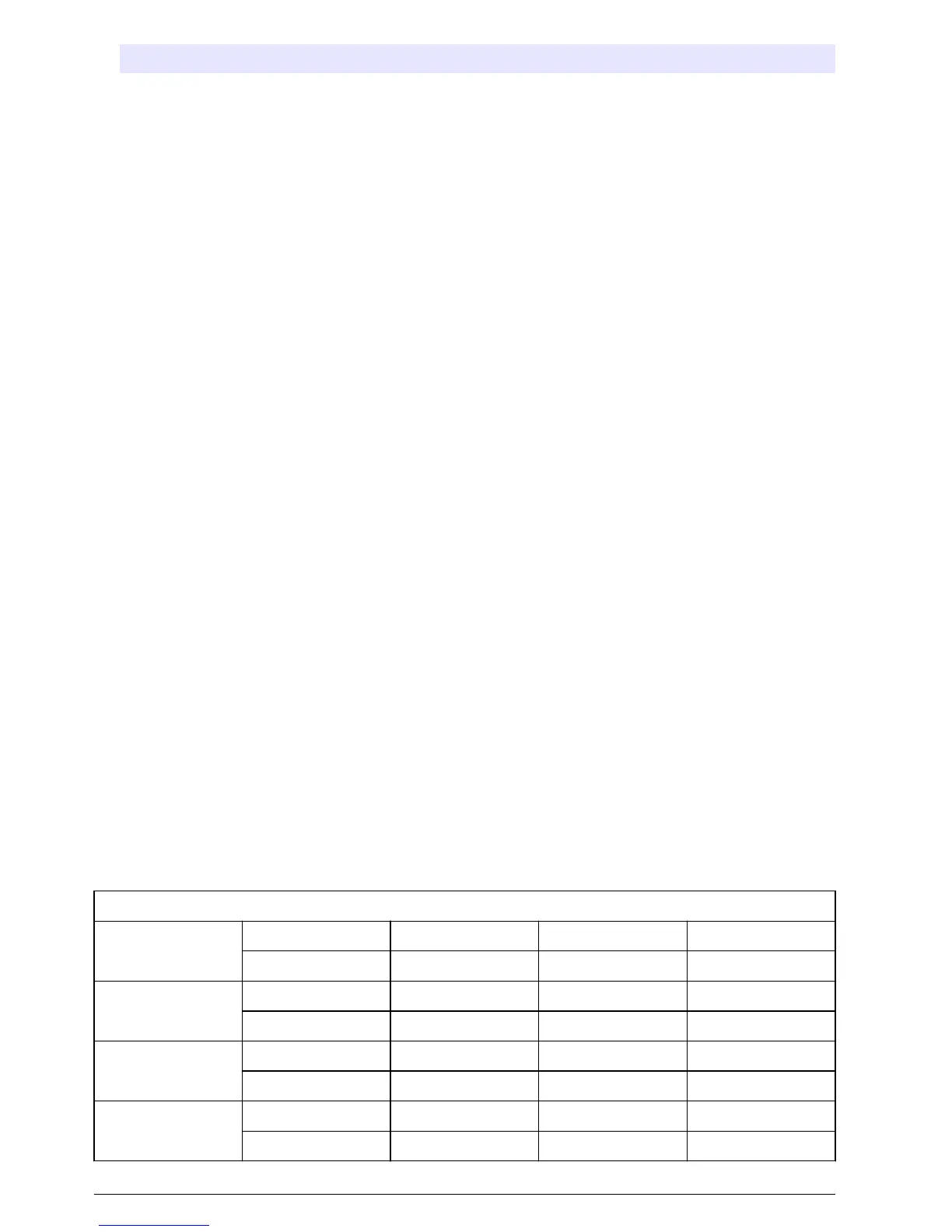

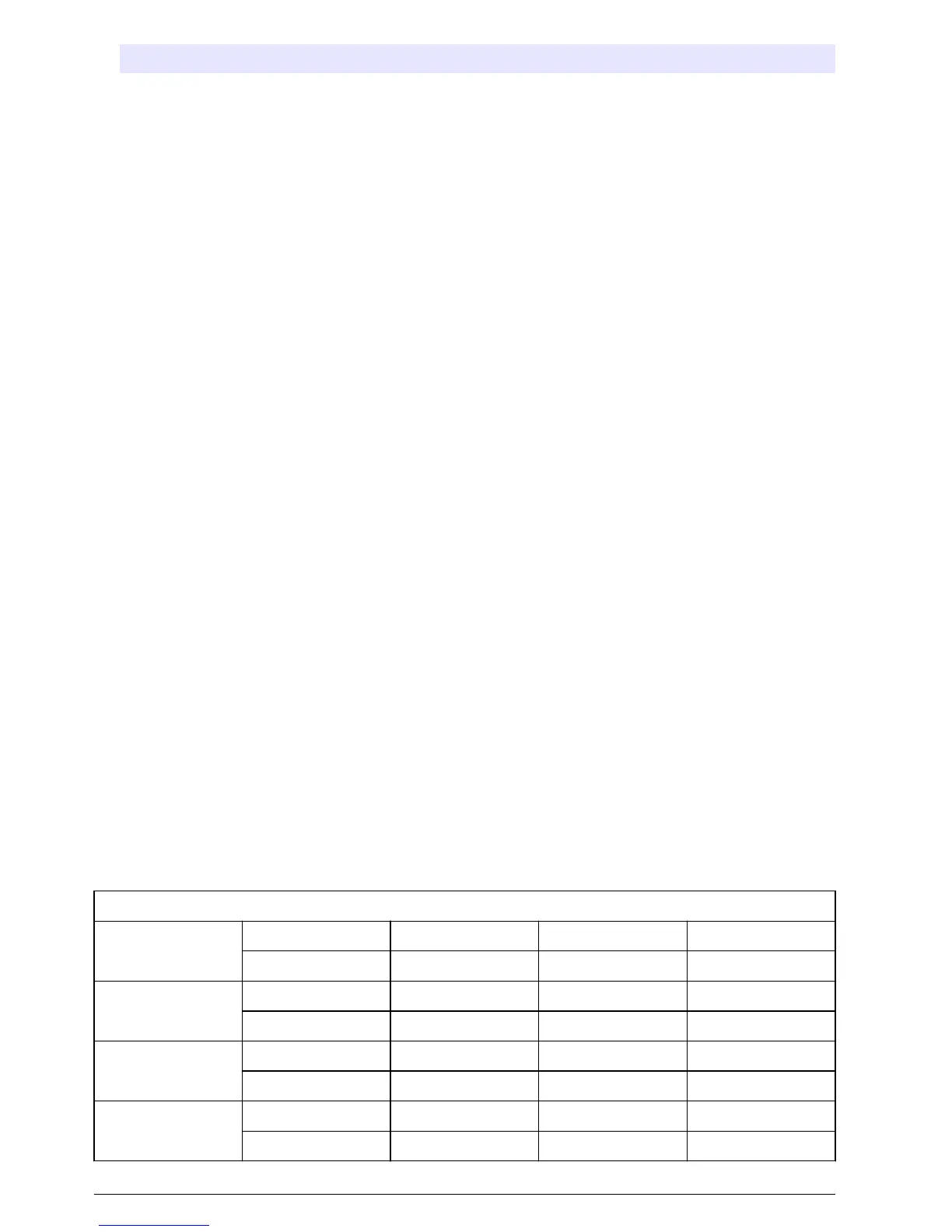

Table 12 Closed conduit—partly full

Metal

Steel Lockbar and welded 0.010 0.012 0.014

Riveted and spiral 0.013 0.016 0.017

Cast iron Coated 0.010 0.013 0.014

Not coated 0.011 0.014 0.016

Wrought iron Black 0.012 0.014 0.015

Galvanized 0.013 0.016 0.017

Corrugated Subdrain 0.017 0.019 0.021

Storm drain 0.021 0.024 0.030

30 English

Loading...

Loading...